Know Your Equipment Costs

Total Cost of Ownership

Construction businesses are asset-intensive and equipment is one of the biggest investments and cost centers. Between initial acquisition costs, over or under utilization, maintenance and repair costs and depreciation, contractors need accurate equipment cost information to easily draw conclusions on how much their assets are costing or earning them.

Tenna’s equipment management software and asset tracking solutions give you insights that better inform you of your equipment costs and total cost of ownership for each asset in your mixed equipment fleet, as well as revenue generated from using and renting out your owned assets that reduces your total costs.

Knowing your accurate equipment cost data helps inform equipment managers and business owners when it makes better sense to own vs. rent and know when it’s time to unload an asset that is costing your more than its working for the business.

Features and Functionality

Analytics

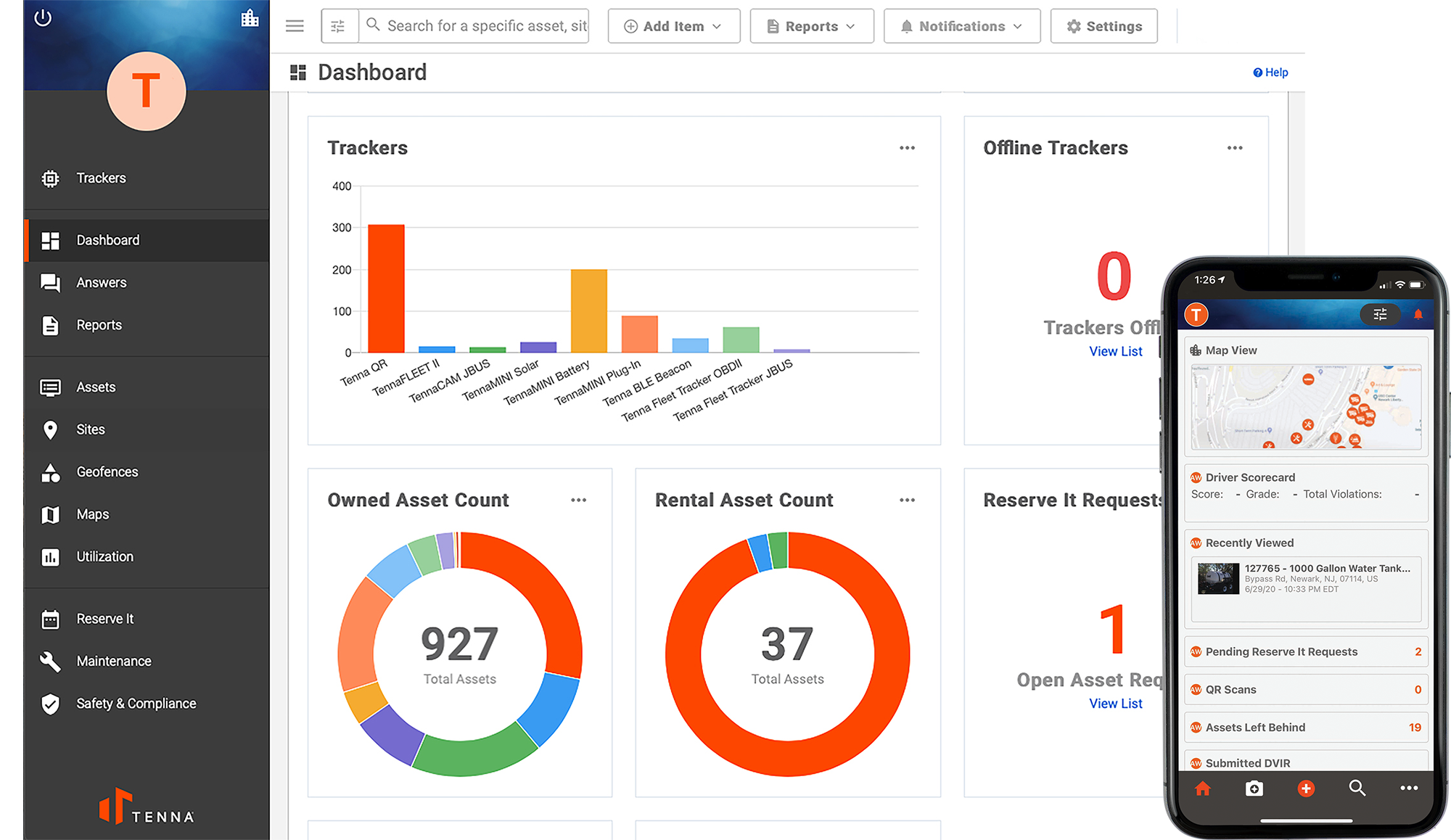

Dashboards provide a high-level view of your fleet. Quickly review your investment costs, equipment utilization, equipment maintenance, repair costs and rental spend to easily draw conclusions on how much your assets are costing you for awareness and opportunities for improvement.

Choose from a variety or standard reports or create your own. Easily report out on your assets’ activity and heavy equipment cost centers like fuel consumption, parts and labor for repairs and operating behaviors over time that can be curbed to reduce costs.

Asset Library

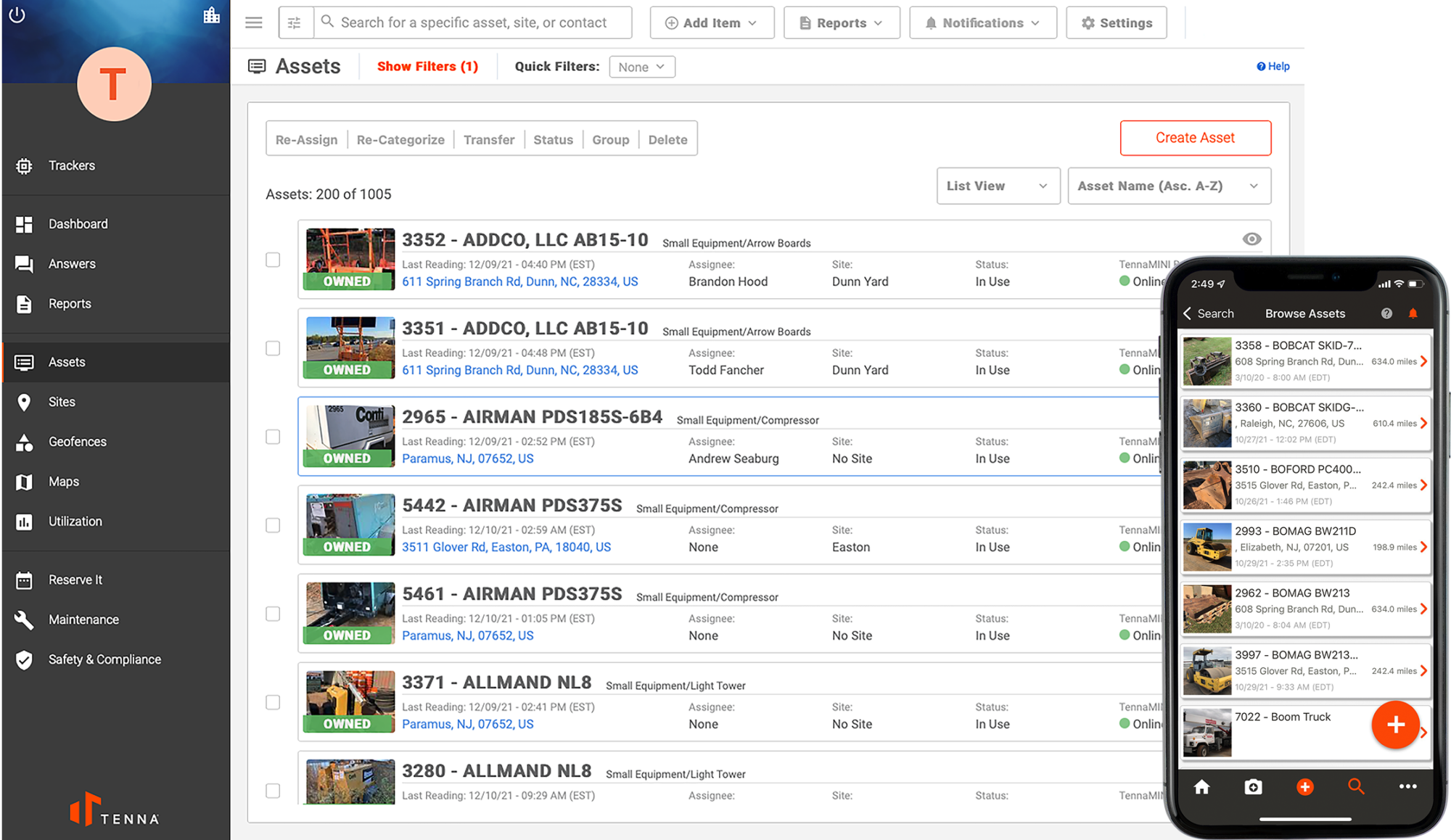

Know what you have and where to save tons of time and money by reducing delays and unnecessary rental costs. Monitor costs associated with owning your assets (payments, interest, fees, book gain/loss, net, etc.), operating them (parts and labor costs) and billing rates associated with using and renting them out to manage how much they are costing vs. earning you.

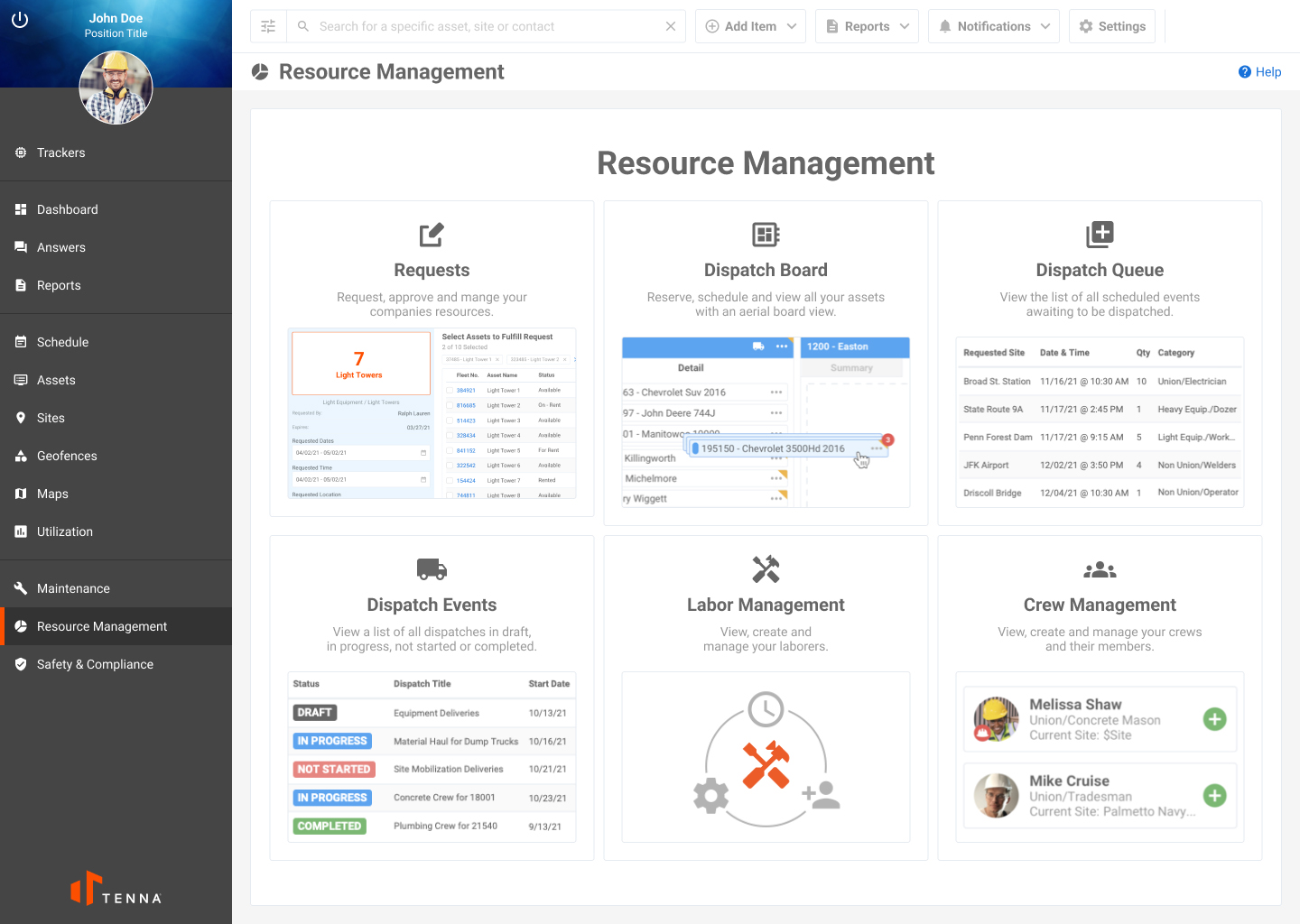

Resource Management

Realtime, comprehensive and flexible resource management of Equipment, Labor and Crews, Trucking and Materials!

Construction Resource Management solution for equipment and labor resource requesting, planning, and dispatching that leverages real-time location, telematics alerts, maintenance needs and other operation insights of assets.

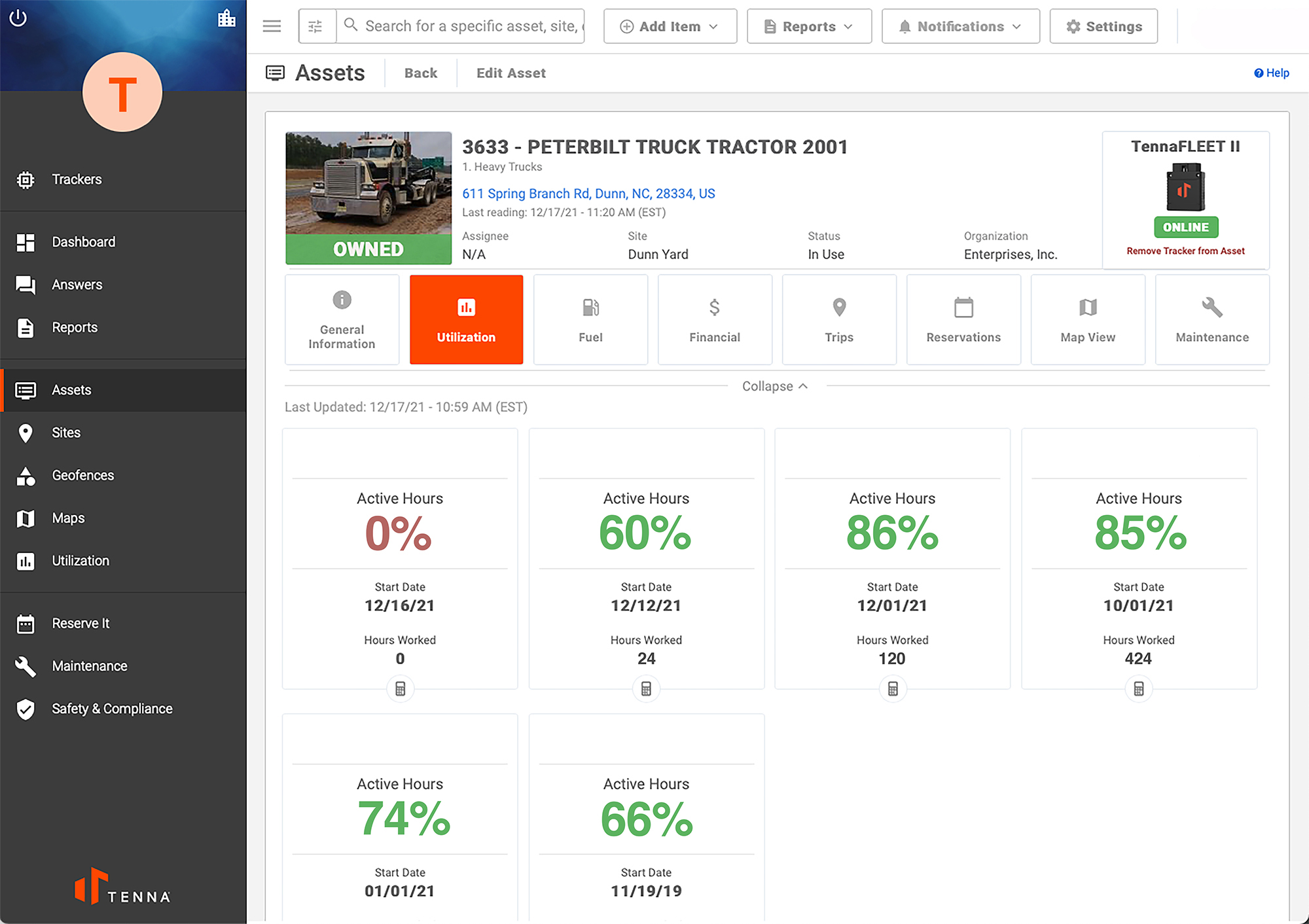

Equipment Utilization (Engine Run Time)

Monitor equipment utilization with telematics to see if each heavy truck and piece of machinery is being sufficiently utilized and getting maximum uptime or learn when you are wasting money on finance payments on assets you aren’t using.

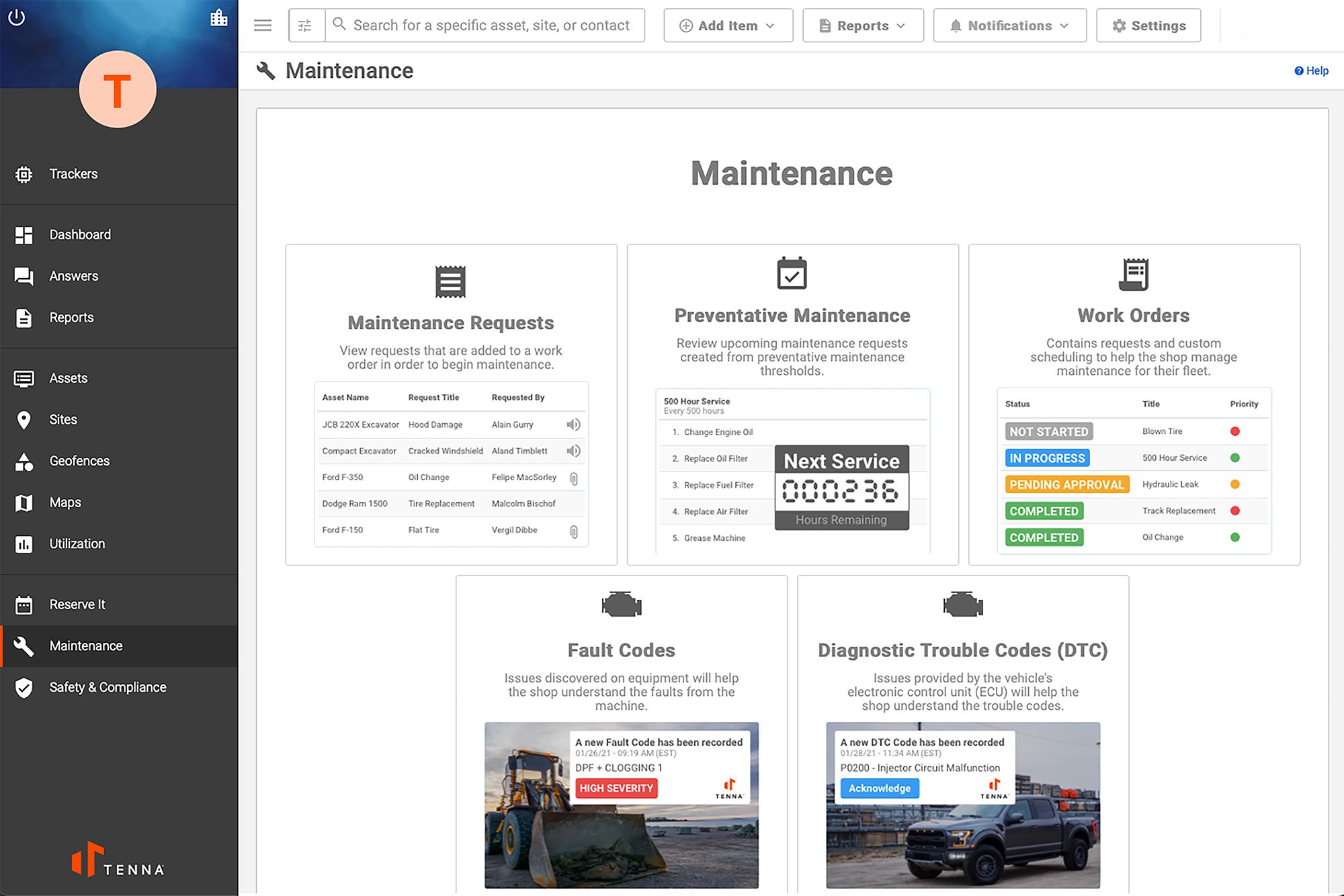

Equipment Maintenance Scheduling and Tracking

Automate preventive maintenance reminders for this major equipment cost center to ensure regular maintenance is performed to reduce costs associated with breakdowns, improve performance and reliability, reduce or slow depreciation and increase your ROI on your owned assets.

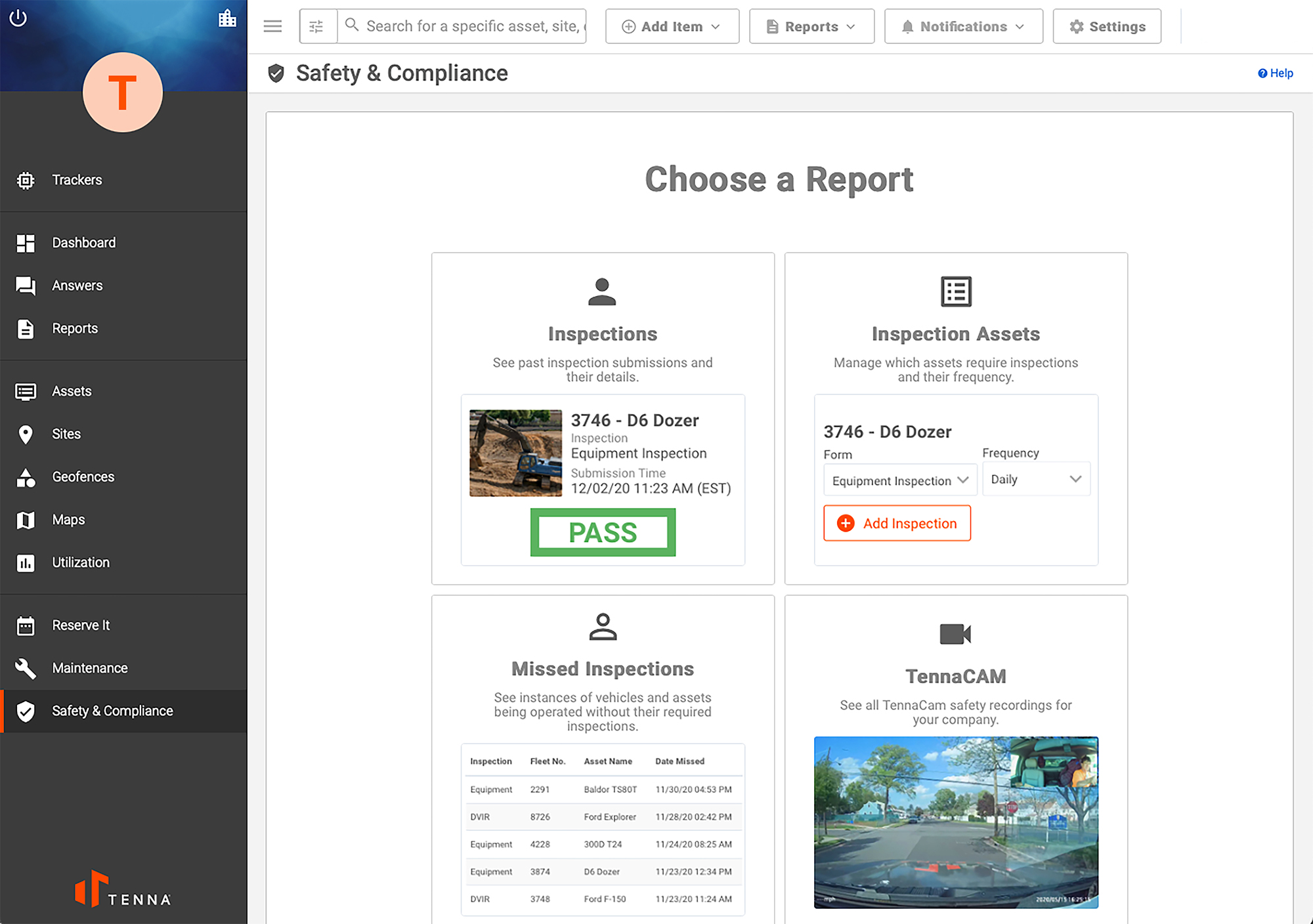

Safety & Compliance

Leverage safety insights from your equipment management software to lower your risk of malfunction, safety issues and repair costs while lowering your insurance premiums for a triple equipment cost reduction benefit.

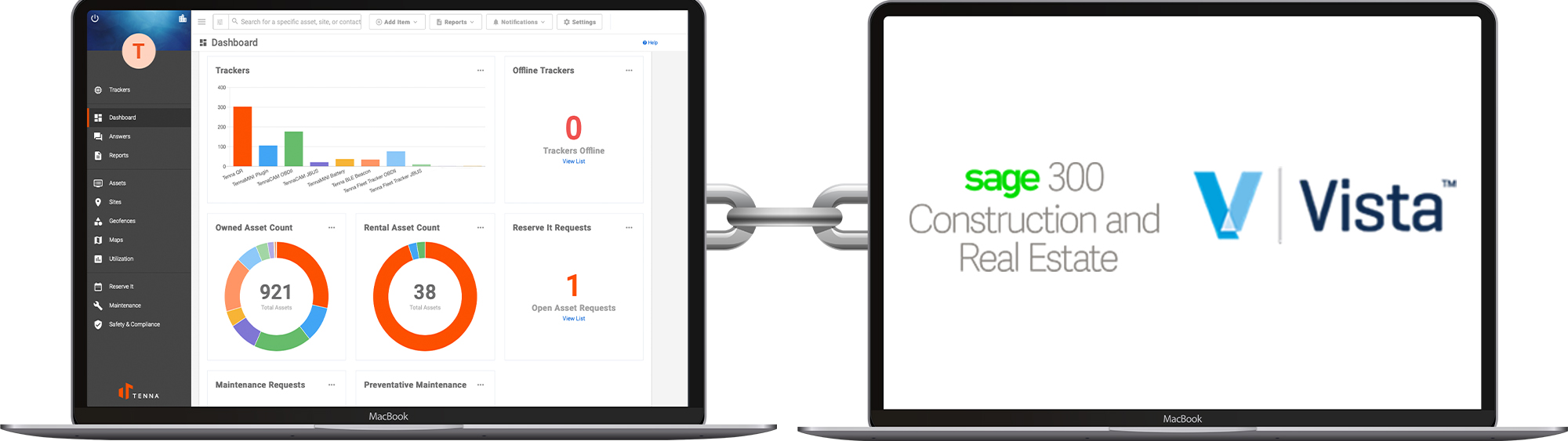

Integrations

Integrate vital equipment cost data from your equipment management software into your ERP/Accounting Systems to ensure complete and comprehensive financial data, fuel your forecasting engine and optimize project margins.

Equipment Management Software Benefits

Better Business

- Increase time savings and efficiencies

- Increase equipment cost earnings and savings

- Reduce ownership and operating costs equals improve ROI

- Improve forecasting and decision making

- Reduce insurance premiums

Total Cost of Ownership White Paper

Read more on how an equipment management system can lower the overall costs of owning and operating your assets.

Tell Us Your Specs!

Schedule a Demo