Safety & Compliance

DVIR Compliance, Safety Cameras, Driver Scorecards and More for Fleet Management

As safety plays a major role in construction, a key component of proper construction equipment fleet management and overall business success involves the safe operation of construction assets and regulatory compliance reporting.

Tenna supports safety efficiencies by letting project, safety and administrative personnel manage and monitor safety and compliance across your entire equipment fleet. Your team can assess driver scorecards and safety camera footage, perform and record equipment inspections and driver vehicle inspection reports for DVIR compliance, use your fleet telematics data to comply with IFTA requirements, and track and reduce violations to efficiently streamline and implement safety across your assets and your business and more.

How Safety and Compliance Features for Fleet Management Work

- Query accurate safety and compliance reports for visibility and to meet regulations.

- Promote awareness and compliance with federal and DOT regulations and company procedures.

- Streamline processes for thorough completion and streamline your business for centralized fleet management and safety data for better visibility and improved record keeping.

- See more insights quickly and efficiently across teams with reports and digital records.

- Apply insights on behavioral trends to improve safety performance and reduce risk of costly violations or maintenance due to unsafe handling.

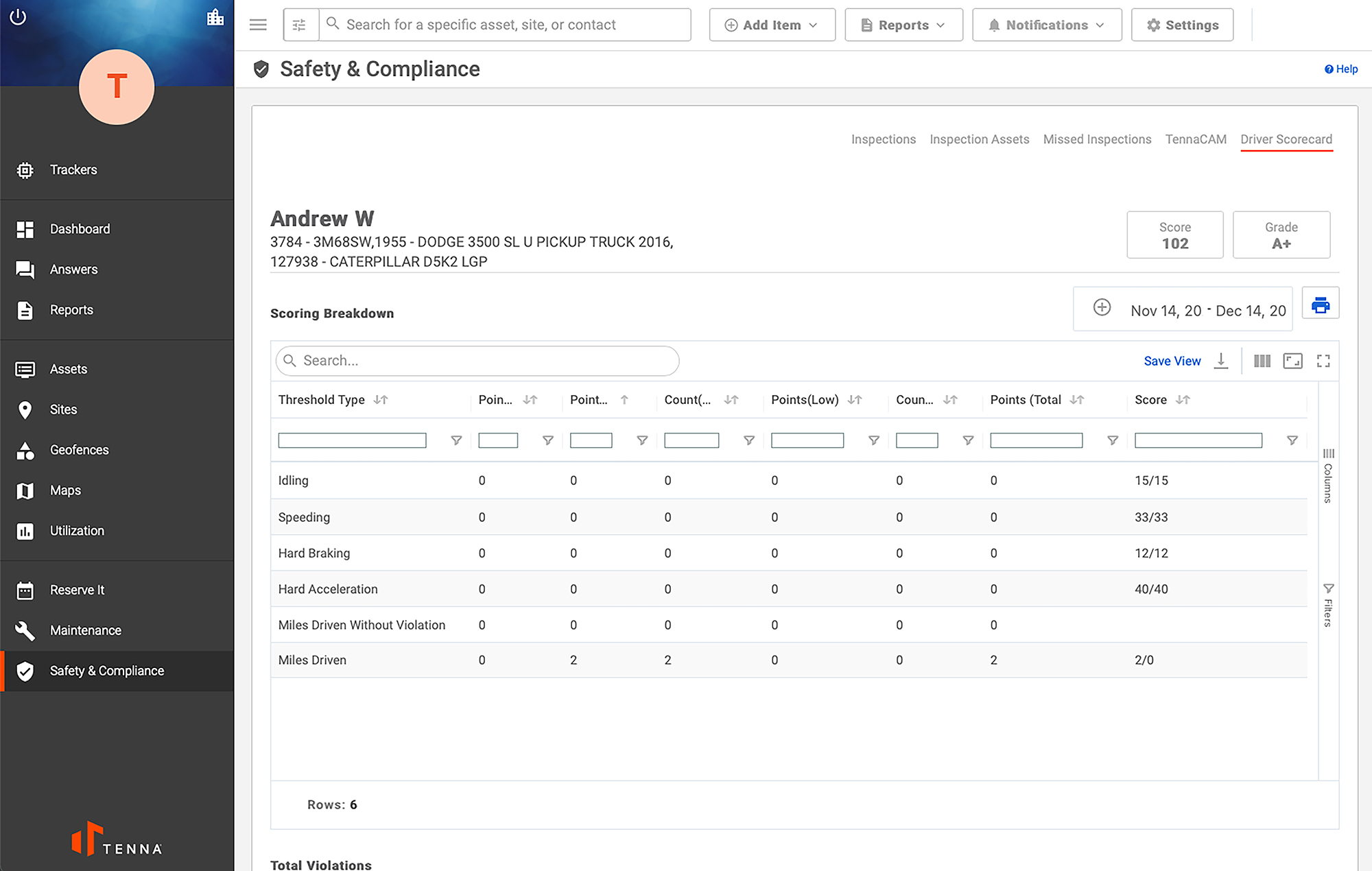

Driver Scorecard

- Maintain visibility into daily individual and collective ongoing company safety performance.

- Measure individual employee driving routines and identify safe driver performance or areas for improvement via driver scorecards easily with built in point system.

- Report on fuel, mileage and performance-related telematics metrics.

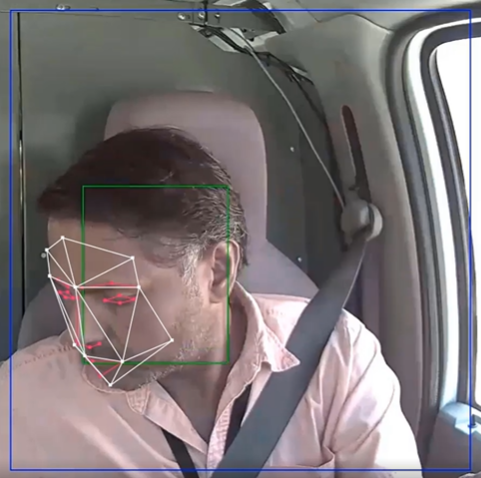

AI Fleet Safety Camera

- Exonerate drivers and resolve claims quickly with interior and exterior camera footage.

- Leverage data to improve driver behavior.

- Complement your driver scorecard with safety camera functionality to get a clear picture of on road driving events.

- Use AI technology to detect common distracted driving behavior and alert drivers in real time.

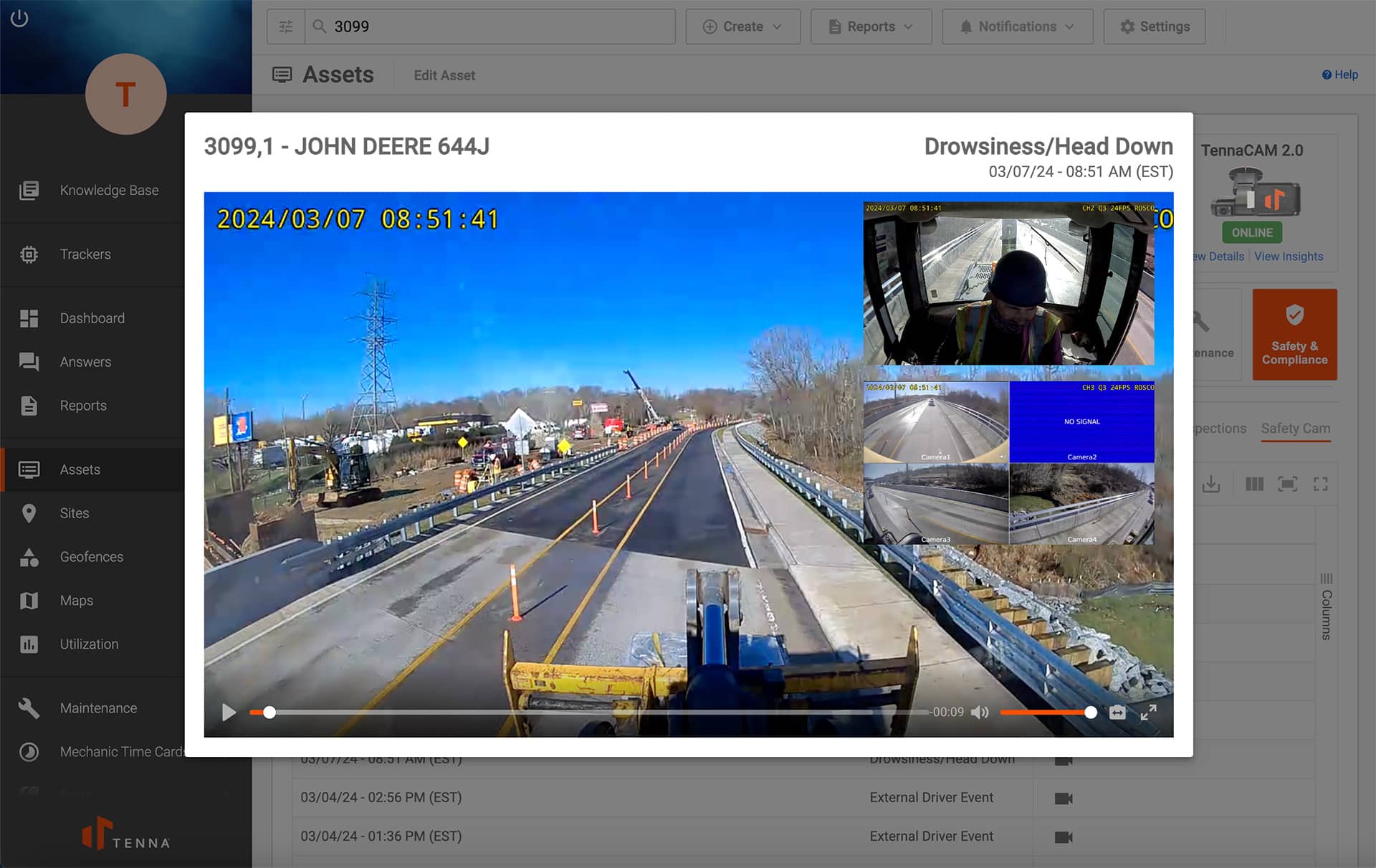

Heavy Equipment Camera

- Increase safe operation of equipment with a nearly 360-degree view around the machine to prevent incidents and reduce risk.

- Reduce blind spots and identify high risk or hazardous areas onsite.

- Capture footage that can be used for better incident reconstruction.

- Expedite insurance claims when incidents happen by providing video evidence to insurance and law enforcement.

- Capture site footage after the machine has been turned off with Parking Mode enabled.

- Great for active roadwork projects and jobsites in close-quarter environments or urban settings.

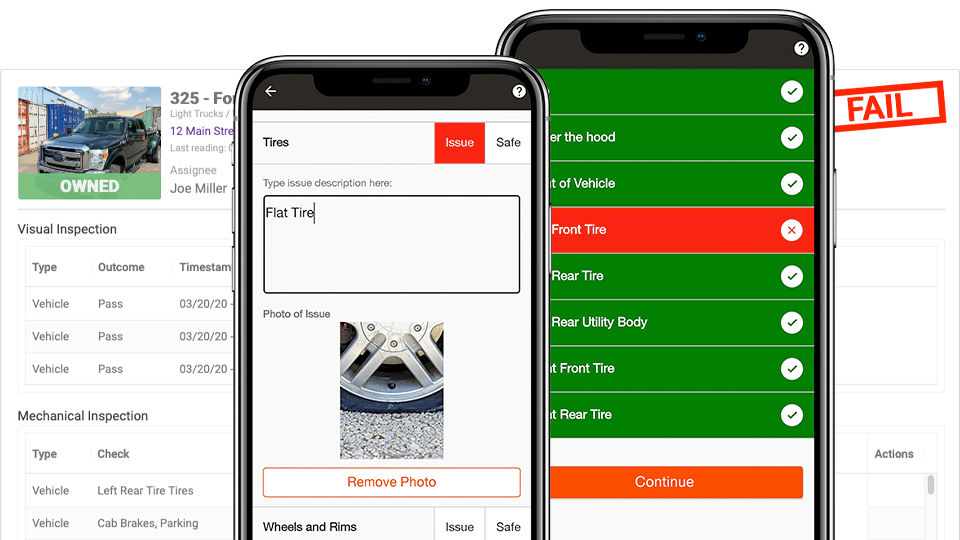

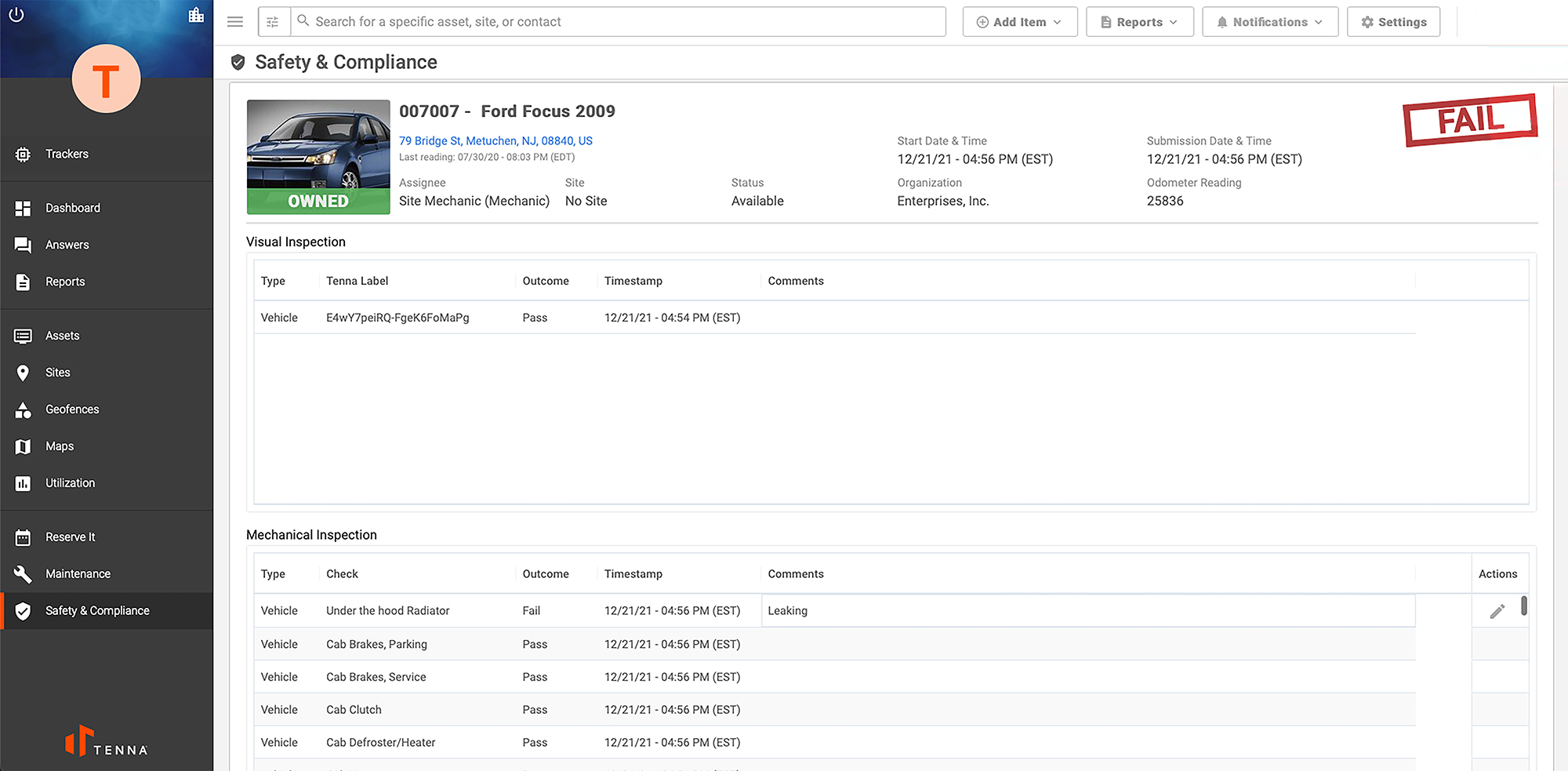

DVIR

- Perform DVIR safety inspections to maintain compliance with DOT safety regulations.

- Proactively keep up with vehicle maintenance.

- Empower drivers to improve safety.

- Enable drivers to perform their responsibilities more efficiently and while reducing time and effort required to complete routine inspections with simple DVIR software.

Inspections

- Manage insurance, certifications and registrations.

- Complete and document equipment inspections and incident/accident reports.

- Perform inspections on your fleet vehicles and heavy machinery with DVIR, Equipment Inspections and more.

- Submit photos, comments, and connect issues to the shop for equipment maintenance and repairs.

- Replace paper inspections, reduce waste and be notified if inspections were missed to ensure they are performed.

- Flag assets as unsafe or noncompliant.

- Facilitate simpler inspection completion via mobile app and capture records digitally.

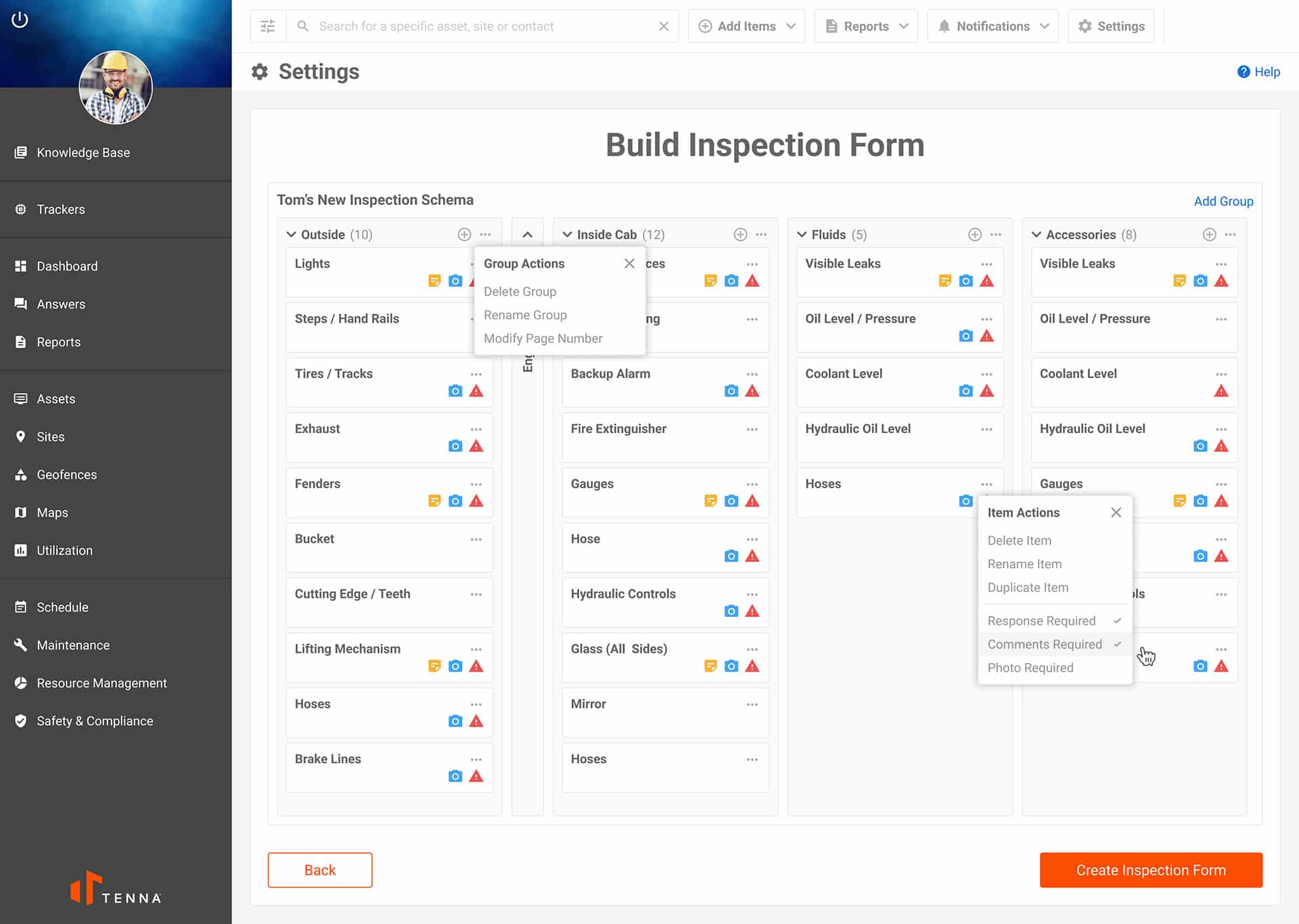

Custom Inspections

- Create new forms for special use cases, specific projects, and more.

- Enforce required fields to get the data you need.

- Mandate signature fields.

- Start from scratch or use an existing Tenna Inspection form and adjust to suit your needs.

- Notice that assets on a certain job site seem to collect a lot of external damage.

- Get as specific as you need to make inspections more meaningful.

Submit inspections from mobile or desktop. - You can even request inspections for dispatched items at the time of delivery.

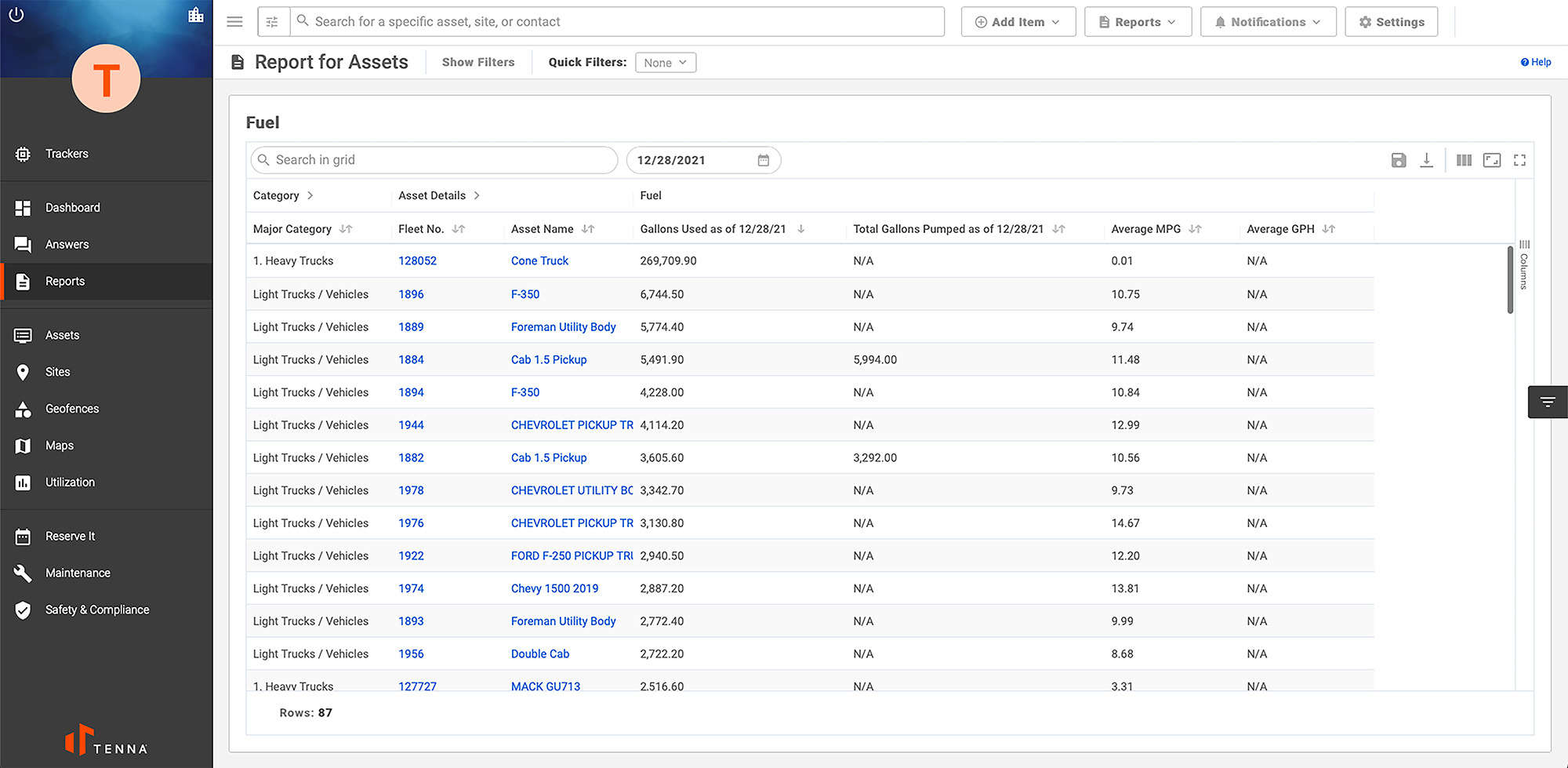

IFTA

- Leverage your telematics data to segment your IFTA-miles per jurisdiction.

- View flexible and convenient IFTA reports by jurisdiction, fuel type or individual vehicle.

- Use IFTA report data to help your accountants calculate your required fuel tax.

- Maintain compliance with federal government IFTA requirements for your fleet.

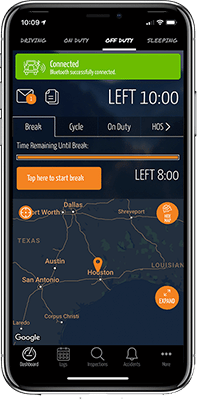

ELD

- Keep track of hours of service (HOS), mileage and how long your drivers are driving overall and between breaks.

- Provide drivers with an easy-to-use app to fulfill their regulatory responsibilities.

- Review the automated fleet management data you need to easily keep accurate records and maintain ELD and HOS compliance.

Safety & Compliance is a Premium Addition to Tenna’s Core Features.

Benefits of Managing Safety & Compliance within Your Equipment Fleet Management System

Increased Efficiencies and Productivity

- Improve visibility over operations and safety performance with GPS equipment tracking

- Improve communication from the shop to the field

- Identify safety hazards or potential performance issues in advance of operation

- Reduce operating costs and avoid costly breakdowns, malfunctions or fines

Better Business

- Reduce risk of safety incidents

- Improve safety by identifying performance issues or flags

- Reduce emergency or unplanned maintenance issues and risks of breakdown and associated costs

- Increase IFTA, ELD and DVIR compliance

- Reduce insurance premiums

- Improve record keeping and documentation

- Win more work with an improved safety record

Safety & Compliance Product Overview

Ready to See More?

Schedule a Demo