Construction Equipment Maintenance

Heavy Equipment Maintenance Software Built for Construction

It is critical that your equipment maintenance solution ensures your fleet remains in good working condition for safe and optimal performance. Non-working assets are extremely disruptive to productivity and budget.

Tenna’s construction fleet maintenance software makes it easier for you and your shop staff to manage preventive maintenance and prolong your assets’ lifespans. Field personnel can schedule equipment maintenance or repairs directly with mechanics when required, report damage from the field using the Tenna App, submit construction work orders, log entries and capture repair documentation to help resell an asset in the future.

We help ensure your assets are kept in top shape to extend their lifespan, reduce your owning and operating costs, and improve your overall equipment management.

How Equipment Maintenance Software Works

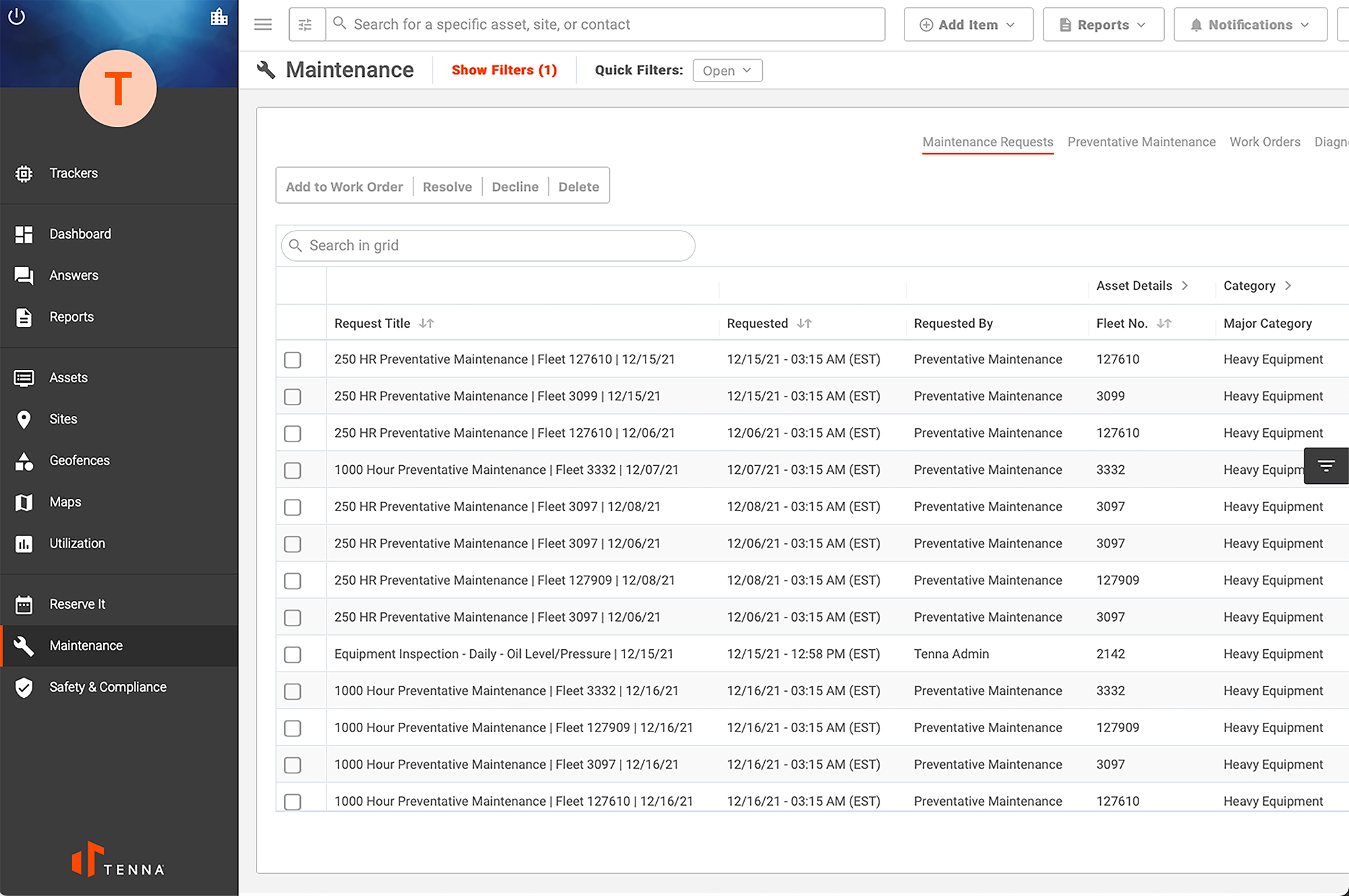

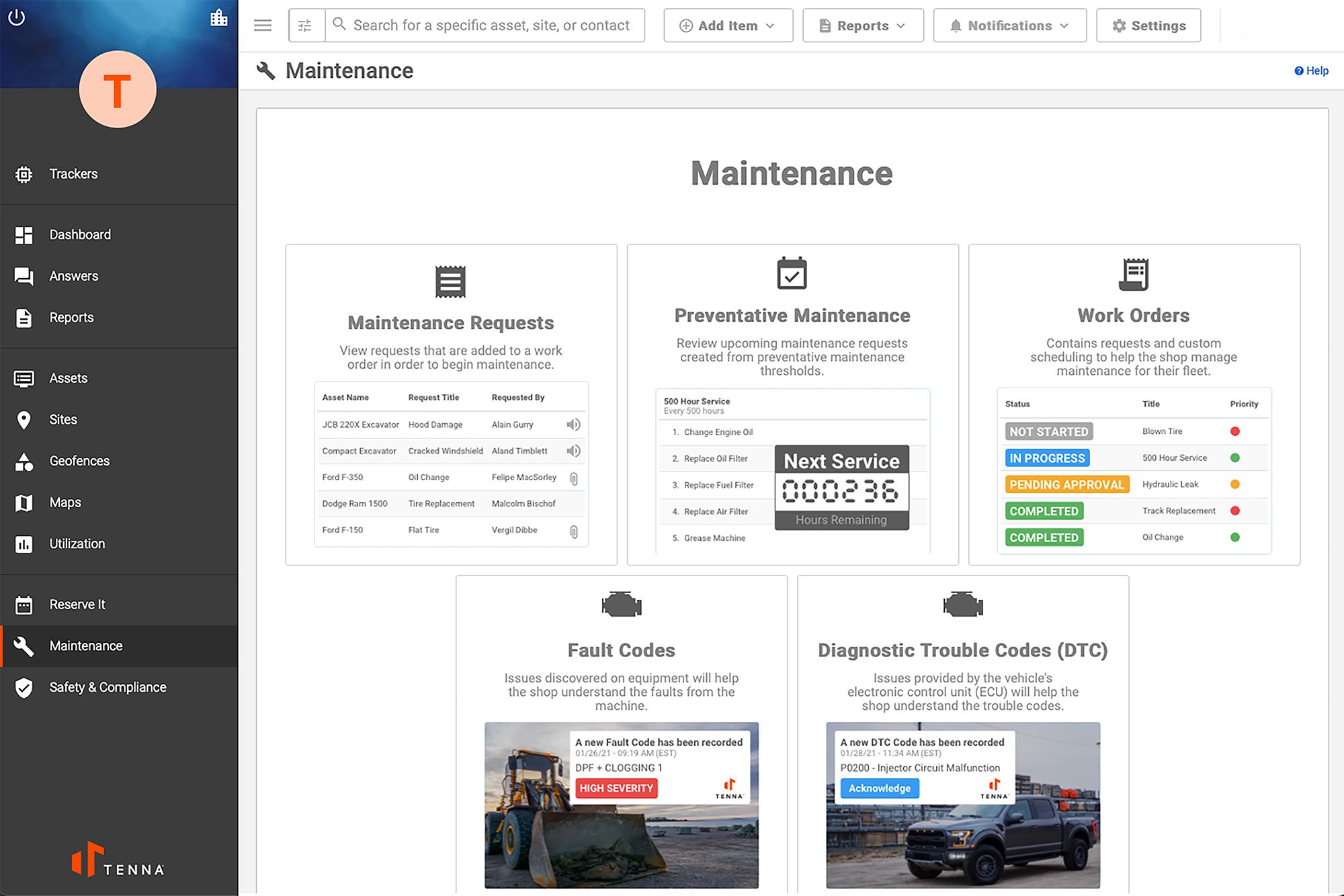

Maintenance Requests

With Tenna’s construction equipment maintenance tracking app you can submit maintenance requests directly from the field with voice memos, text notes and on-the-go submission capabilities for ease and efficiency. Check the status on maintenance work orders to stay informed. See reports for completed maintenance. Log maintenance entries and maintain records of service at the asset level.

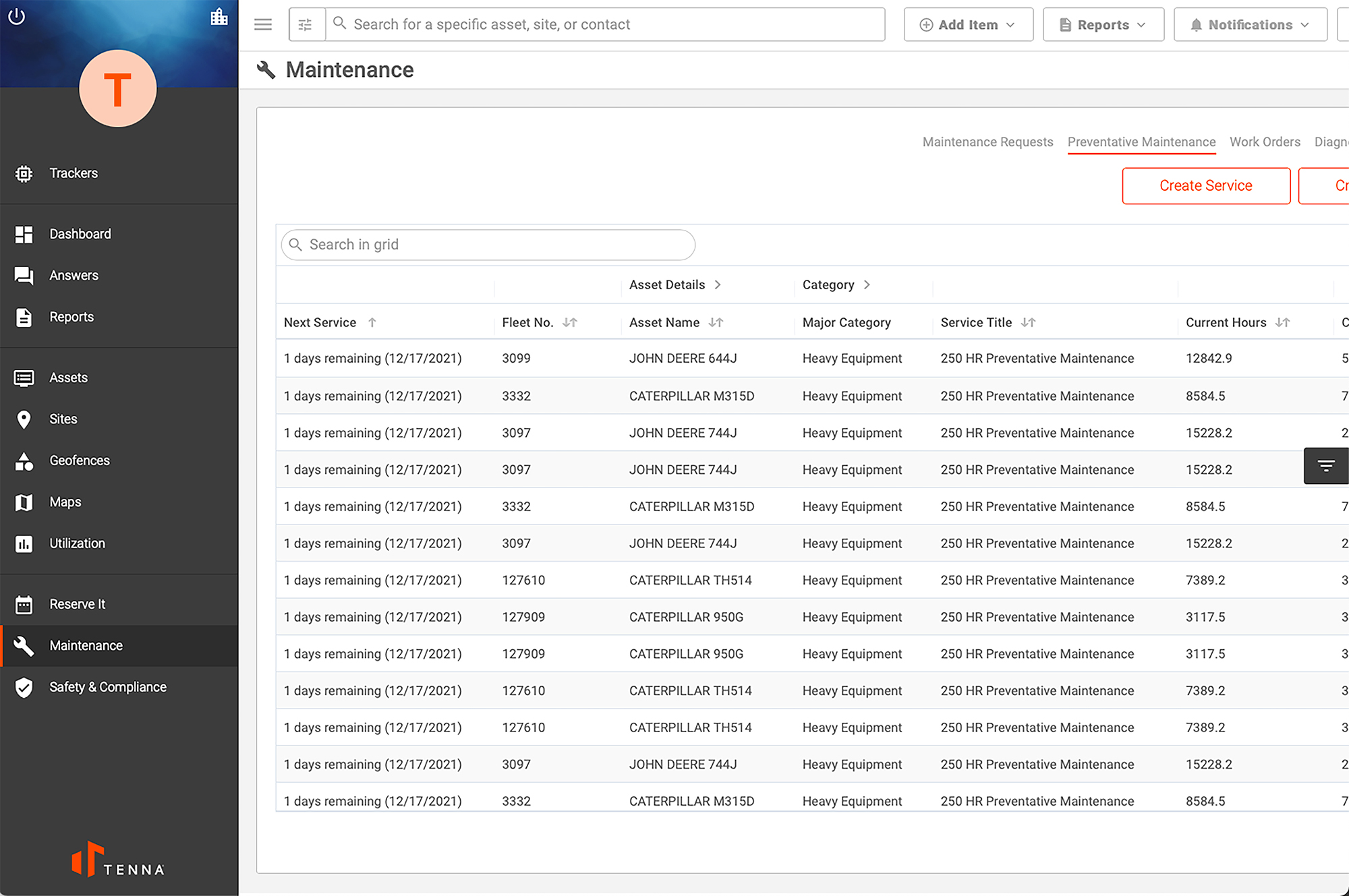

Preventative Maintenance

With Tenna’s preventative maintenance program for equipment, you can set customized maintenance recurrences based on time or usage, as well as automated triggers when service is coming due for effective equipment maintenance management.

Trigger notifications to mechanics and equipment division personnel when repairs are coming due, and update service status and progress in the shop.

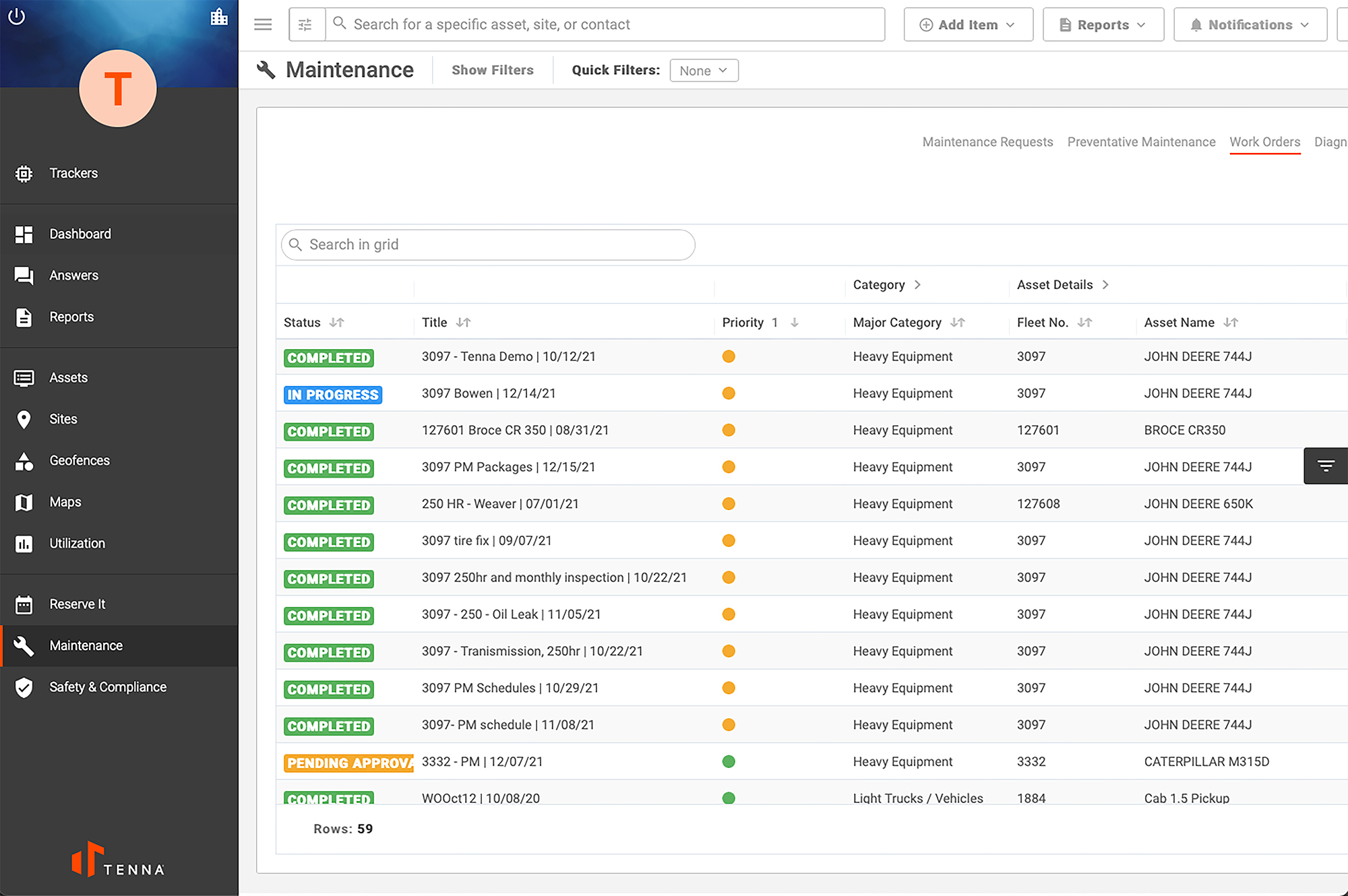

Work Orders

Create construction equipment maintenance work orders to capture maintenance needs for each asset. Capture needs with photos and detail. Document parts and labor associated with each maintenance event for efficient billing and cost control.

Assign work orders to mechanics to optimize schedules and service routines. Leverage work order management to monitor services for individual assets.

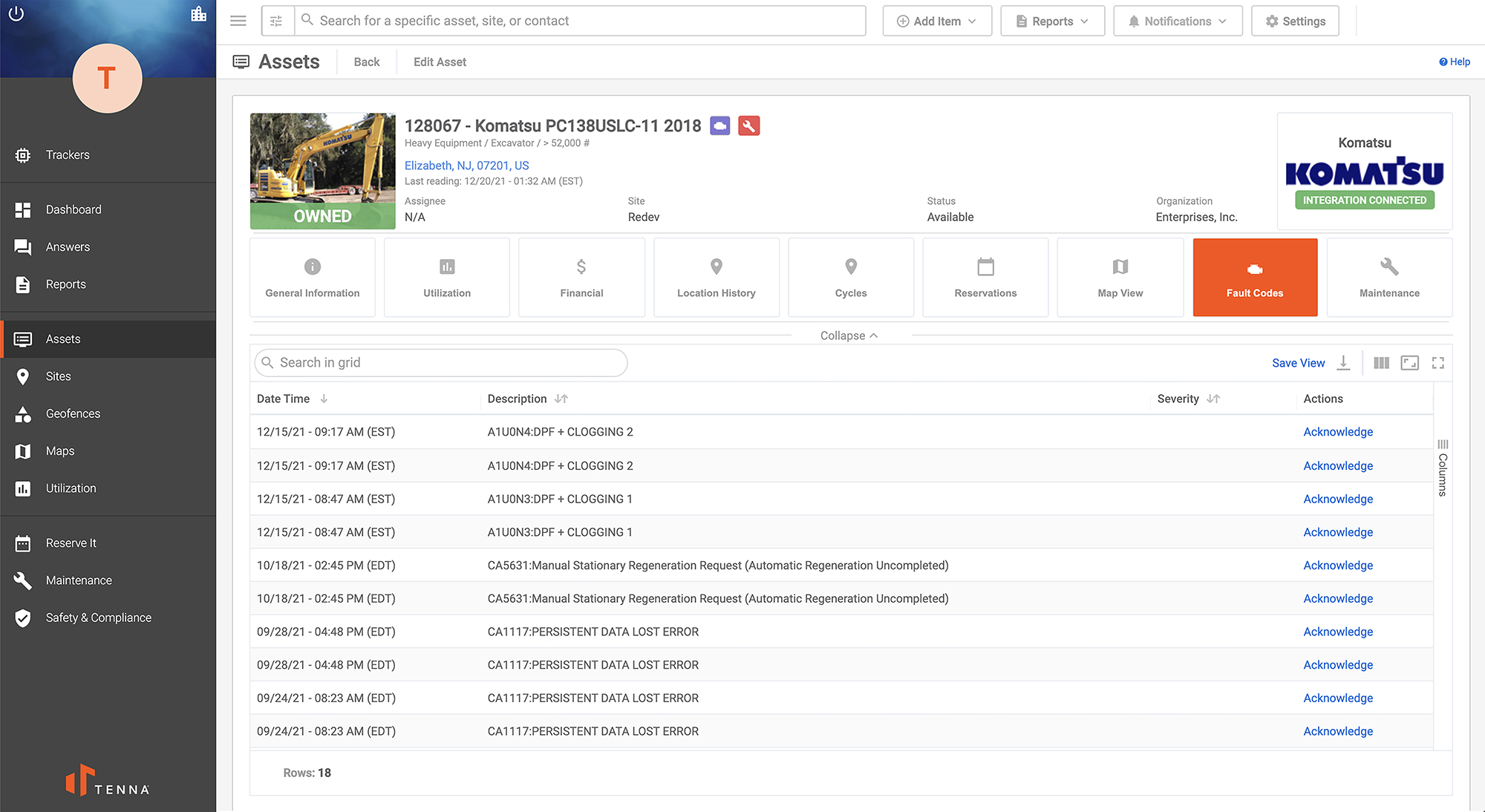

Fault Codes

Issues discovered on equipment and transmitted by the equipment gps tracking device help the shop understand the faults from the machine.

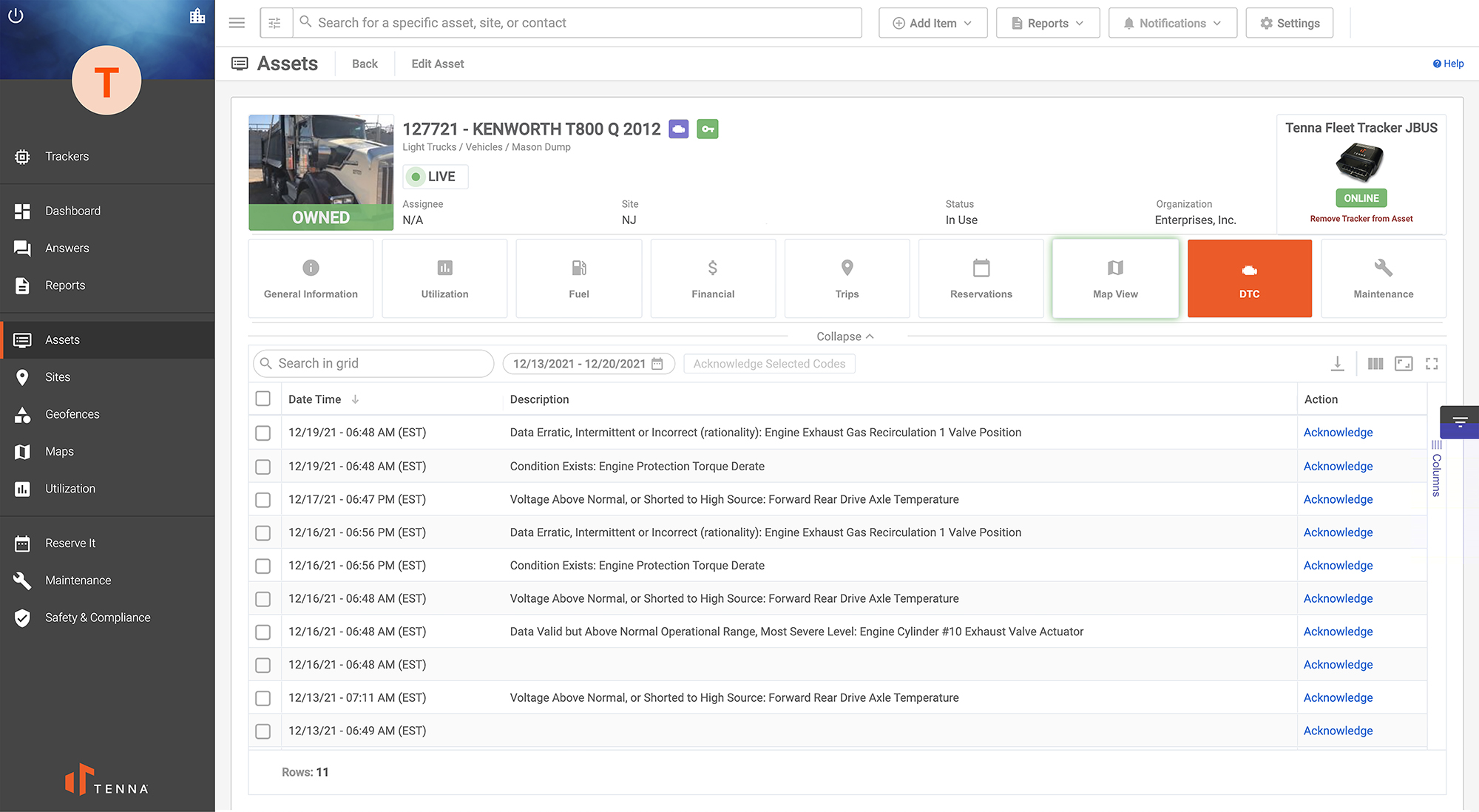

Diagnostic Trouble Codes (DTC)

Issues provided by the vehicle’s electronic control unit (ECU), via the fleet gps tracking device, help the shop understand the trouble codes and root causes of the issue.

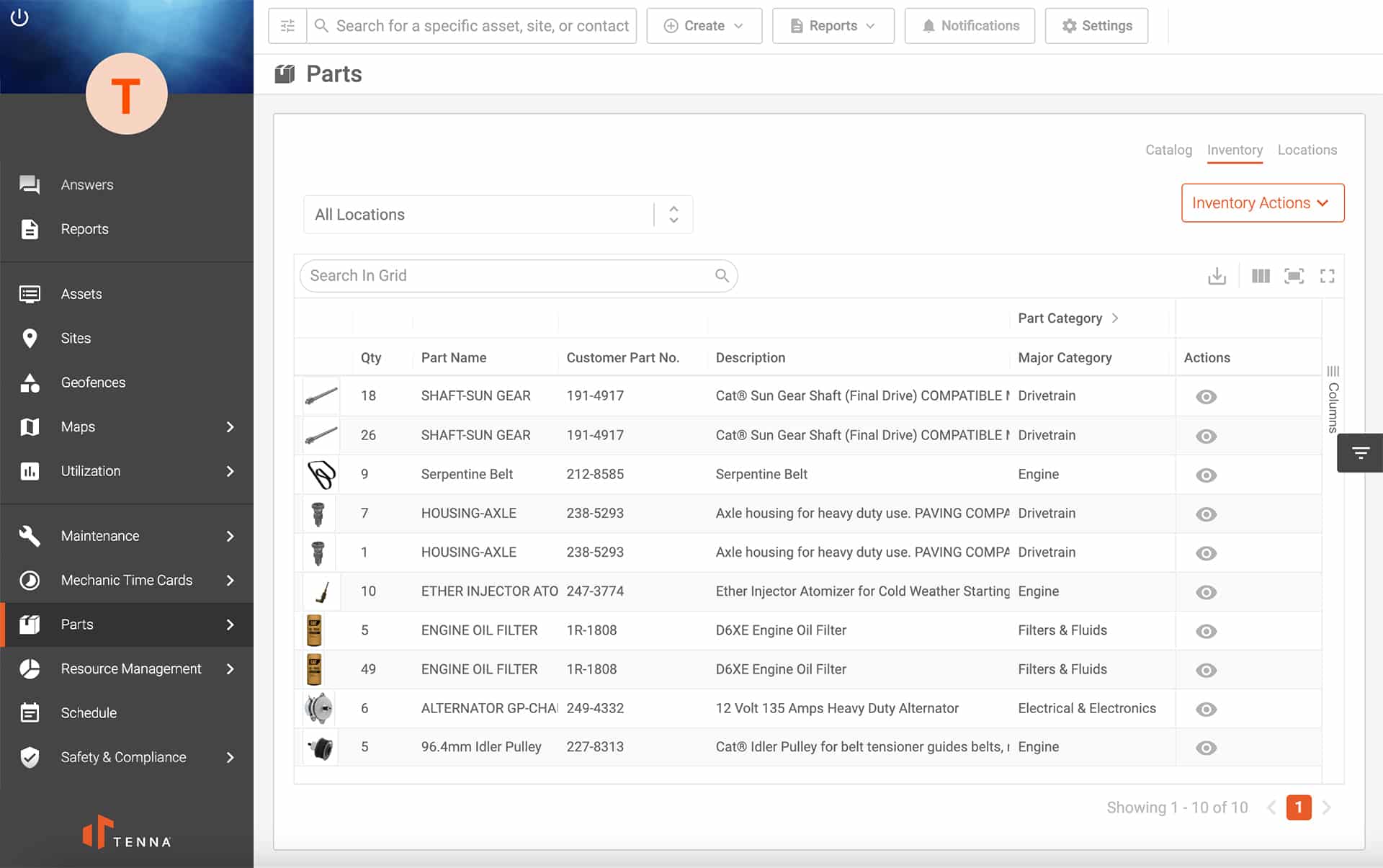

Parts Management

Request and locate parts faster from the field and manage inventory more efficiently with Tenna’s parts and inventory management solution. Our CMMS alerts you to minimum quantities as well as when parts are fulfilled, so you can avoid scheduling delays and overstocking to reduce waste and make better budgeting decisions.

Easily maintain your parts catalog and parts used against each asset, and keep track of usage, warranties and moves across locations.

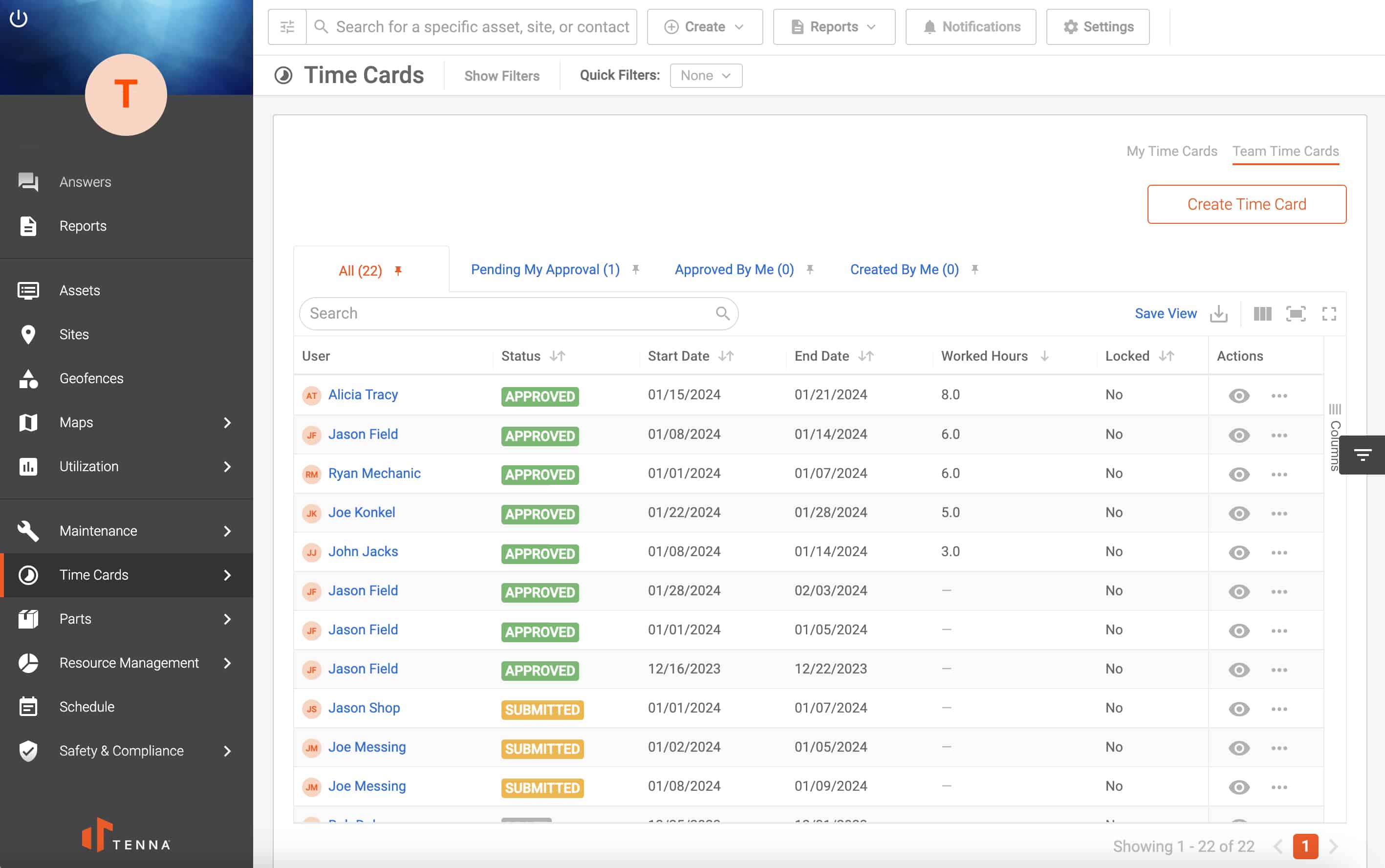

Mechanic Time Cards

Tenna’s mechanic time cards power crews with easy, digital productivity tracking. Capture mechanic time worked against your work orders and maintenance requests. Cost codes are customizable, giving you full visibility into how much your equipment costs to maintain.

Streamline the payroll process. You decide how detailed to include in your time cards and set approval levels.

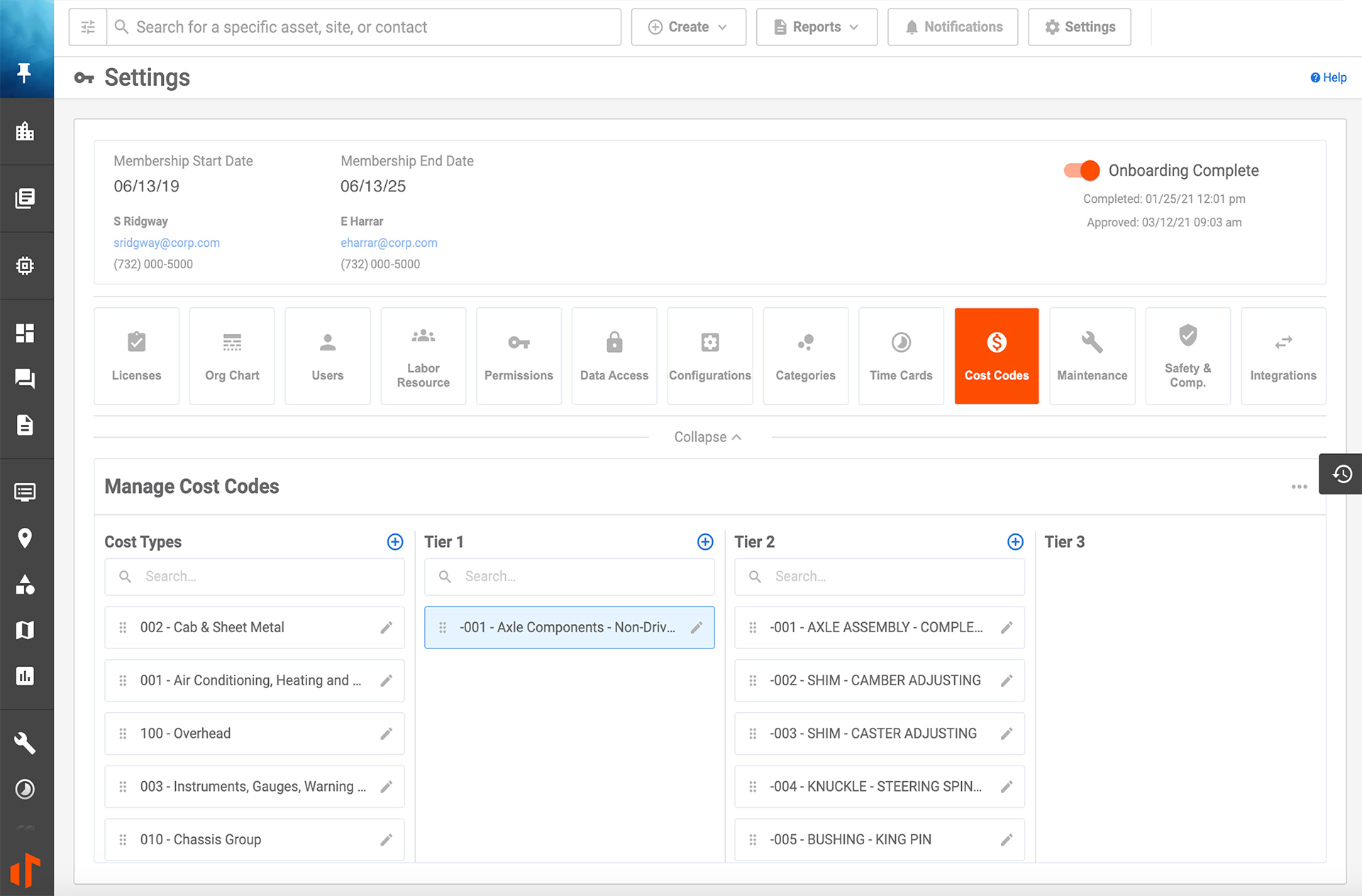

Cost Codes

Gain a comprehensive understanding of your projects’ finances with Tenna’s customizable cost codes feature. Track spending against labor and materials. Plus, our CMMS integrates cost codes with maintenance data so you can see what’s being spent on construction equipment maintenance and repairs.

Repair Documentation & Reporting

Capture upcoming service needs at the asset level for visibility and awareness. Analyze all assets with upcoming maintenance or repair needs, and see construction work order progress and status.

Document and report on repairs and services performed for efficient record keeping and added value and during resale.

Maintenance is a Premium Addition to Tenna’s Core Features.

This product is valuable for improving communication between your field and shop teams, keeping equipment in safe and optimal working condition and expediting repair needs.

Benefits of Construction Fleet Maintenance Software

Tenna improves your overall equipment maintenance management by improving visibility and communication between the shop and the field to keep assets up and running and keep projects outfitted with the resources they need when they need them.

Better Business

- Reduce costs by avoiding and reducing emergency maintenance and repairs expenses, operating costs, and mechanic labor costs

- Reduce emergency or unplanned maintenance issues and risks of breakdown

- Protect the capital investments of your assets and increase the value during resale

- Increase ROI on owned assets

- Improve safety by identifying performance issues or flags

- Improve record keeping and documentation

Increased Efficiencies and Productivity

- Increase project productivity with fewer resource delays and improved response times to repair requests

- Improve schedule efficiencies in the shop and in the field

- Increase asset uptime and lifespan

- Improve asset performance and equipment utilization

Equipment Maintenance Product Overview

Want to See What Tenna Looks Like?

Schedule a Demo