Construction Operations Software

Your industry partner bringing you value in the field, shop, and office.

Onyx Paving recovered $160,000 worth of stolen fleet with Tenna.

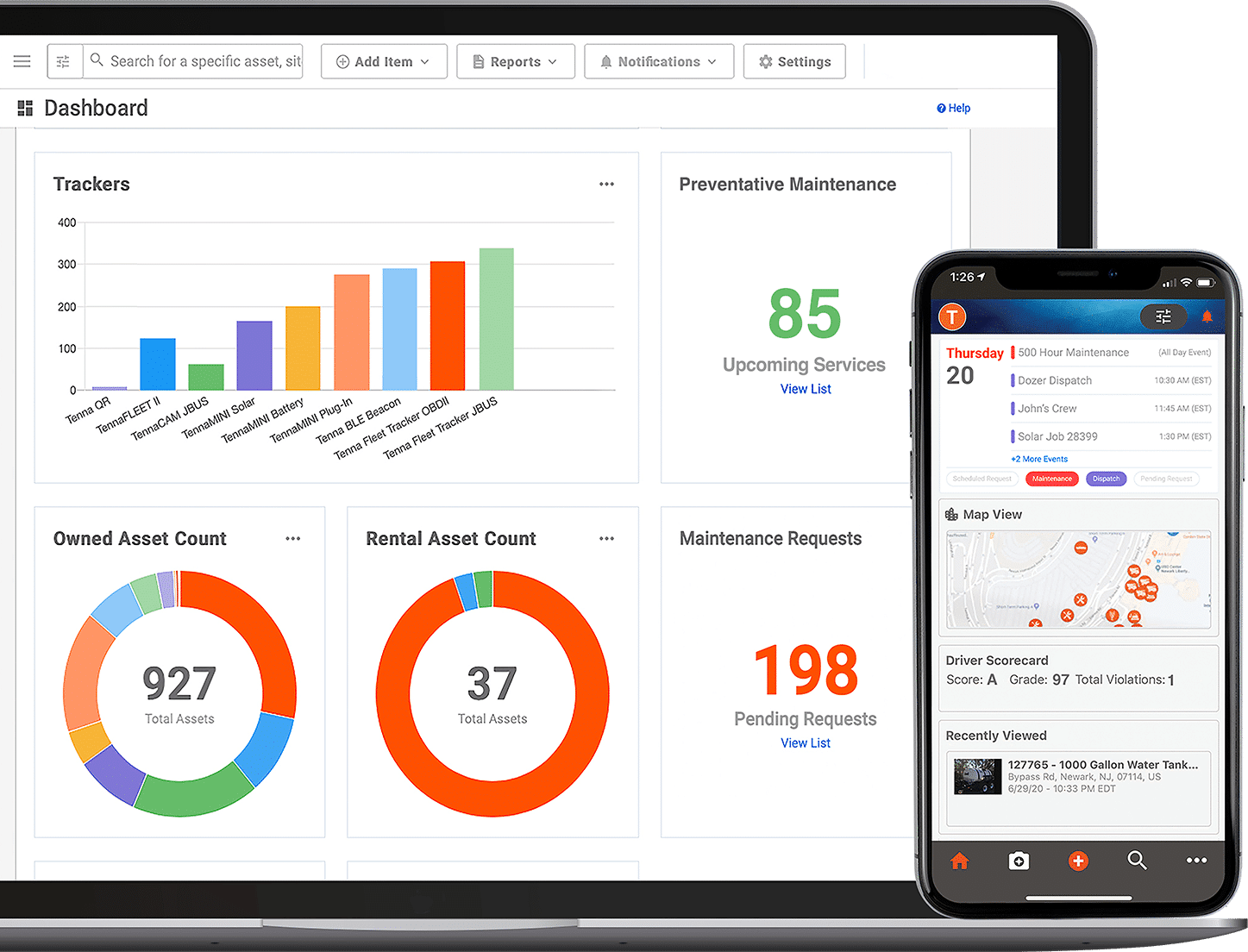

Tenna is the construction operations software that revolutionizes equipment management.

A unified asset tracking system for your mixed fleet. We are the standard for the construction industry.

Don't Just Take It From Us!

See what our 400 customers have to say.

Hear what our valued customers are saying about Tenna’s asset tracking and management solutions.

Why Tenna?

Built for Construction

Built on over 100 years of construction experience, we speak your language. We experienced your challenges firsthand which is why we built Tenna. We use our extensive experience, knowledge and expertise in the construction industry as the foundation for our construction equipment management system. We understand that knowledge is power. Actionable information, location and reporting will give you a competitive edge.Customer Stories

What matters most to our customers is what matters most to us. As the saying goes, actions speak louder than words. And we also know our customers’ words speak louder than ours. Hear what they have to say!Implementation

Onboarding and Implementation is more than checking off the boxes and we know “Slap and Track” is a road to failure. We ensure we do it right the first time by partnering with your team and “Tenna Certifying” them to ensure they too are system experts. Our team of heavy-diesel mechanics have over 130 years of combined construction fleet experience and will roll up to your jobsite, yard, or office to get the job done right.One Platform

From heavy iron to vehicles and mid-sized equipment, to consumables, Tenna’s asset tracking system gives you a complete view of your entire mixed equipment fleet and other assets on One Platform. You can consolidate multiple systems, save time and money, and get a dedicated partner to manage your all your stuff and plan your operations.Customer Success

Our Customer Success team is here for you from the beginning until always. Even after your system is up and running and your end users know what to do, we continue to provide you with the support you need. We’ve always got your back.Integrations

Tenna offers a variety of software integrations include Accounting/ERP, Project Operations Systems and OEM integrations. Having Tenna as an integrated construction equipment management system results in a true business’ technology ecosystem.

Previous

Next

Our Construction Operations Solutions

Save time, money and keep management and field employees informed and productive.

Track vehicles and heavy trucks in real-time, slash idle time, minimize risk of theft, optimize schedules and save on fuel.

Ensure assets are kept in top shape to extend their lifespan, reduce ownership and operating costs, and improve overall equipment management.

Allow mechanics to easily capture their time against sites, assets, work orders, and maintenance requests to improve efficiency, track employee productivity, and streamline payroll processes.

Create a centralized parts catalog and manage your parts inventory across multiple inventory locations. Track the life, warranty and costs of parts associated with assets over their life.

Excel at equipment scheduling and improve productivity by ensuring you are getting the right assets and crews for the job. Handle asset requests and communication between job sites with automated notifications and smart approval flows.

Assess driver scorecards and safety camera footage, stay in compliance with equipment inspections and DVIRs, and reduce safety violations.

Leverage AI-assisted video telematics to exonerate your drivers when they are involved in incidents that are not their fault. Provide real-time feedback to drivers to correct unsafe driving behaviors and warn them of potential incidents in the road ahead.

Ensure safe equipment operation, identify hazards and document maintenance and repair needs with customizable inspections. Modernize your workflows to connect the field, shop, and safety team with easy-to-use mobile inspections.

Integrate Tenna data with OEMs, accounting and ERP solutions, equipment rental providers, and other construction software platforms for truthful data and improved visibility across your organization.

Linking All Your Construction Systems

Already have some construction management systems in place that you don’t want to let go? No problem! We’re partnered with other construction technology providers to give you all your critical information on one platform.

We've Been in Your Boots

We experienced your challenges firsthand which is why we built Tenna. We’ve been where you are and understand that knowledge is power.

See Tenna in Action!

Schedule a Demo