Construction Equipment Costs To Consider

Equipment management software can be leveraged to monitor your construction equipment utilization and preventative maintenance as well as manage the total costs of owning and operating your assets.

In this page you will find construction equipment costs related to real construction scenarios you are probably familiar with, as well as ways to use fleet management and asset tracking tools to improve your equipment cost control.

Remember that the cheapest equipment management solution may not be the best solution.

We’re not suggesting that you throw away money but be sure to evaluate how the system solves your business needs and provides the functionality that meets your requirements to make a best value decision; don’t just look at the numbers.

Be mindful during the quote/proposal stage that you truly understand the cost-benefits. Many equipment management solutions will throw down numbers that are hard to resist but be sure there aren’t any hidden costs and terms that will make it virtually impossible to switch the system.

What your Construction Equipment Could Be Costing You

Maintaining an equipment fleet is one of the biggest capital investments of a construction business. Fortunately, construction technology today can help contractors better manage their equipment and their many associated costs.

Equipment management systems shed light on your true equipment costs through continuous tracking, logging and monitoring. Having this knowledge and insight directly impacts your decision making around equipment related expenses and planning. When deciding whether an equipment management system is worth your investment, it’s important to review what your equipment could be costing you today.

In most cases, the cost of one emergency repair or issue is roughly the annual cost of an equipment management solution. If you can eliminate even one emergency repair per year, you will find that your equipment management system will have paid for itself.

Based on our 100+ years of industry experience, we’ve gathered six typical equipment costs and scenarios you are probably familiar with.

When deciding whether an equipment management system is worth your investment, it’s important to review what your equipment could be costing you today.

1. Breakdowns And Repairs

Depending on the type of machine and type of failure, the average cost of a breakdown can vary. Regardless of the actual dollar value, it’s always a blow.

Engine failure on a Manitowac 10,000 crane, for example, can run north of $36,000 to repair. Conversely, the average cost of preventive maintenance, typically built into standard operating costs, is between $4,000 and $6,000 per year.

If your equipment management system can help you keep up with routine maintenance and save you from just one breakdown, you will have covered the annual cost of your software. If the system helps you streamline your preventive maintenance scheduling and execution, that will prevent future breakdowns, multiplying your savings.

2. Hoarding

Monitoring your equipment utilization (how many hours were logged over the past day, week, month, etc.) can reveal under utilization at the asset level.

Knowing this at the project level can prevent jobsite hoarding as well as the need for unnecessary equipment rentals. If a machine has been on a jobsite for months but was only run during one shift, that machine should be considered available for use elsewhere.

Eliminating three to six months of rent for one Komatsu PC238 Mini Excavator at $6,500/month (plus pickup and delivery charges, taxes, service fees and final inspection dues) by mobilizing an owned, unused one being hoarded on a jobsite will very likely meet, if not cover, the annual cost of your equipment management system – and that’s just for one rental asset!

You’ll get greater value using and generating revenue for your owned assets that contributes to their loan payments than you will incurring steep rental costs.

3. Repurchases

The same goes for repurchases caused by a lack of visibility. Duplicate repurchases of a tool or mid-sized asset (do you really need 11 ladders on one job at $500 each?), or a single repurchase of a piece of heavy equipment bears a heavy expense burden.

Concrete demo saws, a common repurchase, sell for about $1,200 from Hilti, with blades costing another $100 to $150 each. Concrete saws easily go missing (or get stolen due to their light weight) and then, before you know it, new ones have multiplied in your yard as your teams have urgently needed them and now you own 10 or 12. These will soon disappear on you again, and the cycle continues.

A paver, for another example, could cost anywhere from $250,000 to $500,000+ depending on age, make and model, which can easily equate to a finance payment of $10,000+/month (understanding the intricacies of credit score, terms and other factors).

Equipment management systems are useful for preventing these unnecessary purchases, as well as theft. No matter how large your fleet, avoiding $120,000 in annual finance dues (again, for one single unnecessary asset purchase) more than covers the annual cost of your equipment fleet management system.

4. Logistics

It costs a lot to move a broken or non-performing piece of equipment to a project site.

Even after shopping around for the best freight rate, hauling costs vary depending on machine weight and width, plus permits for heavy hauling and oversized loads both in and out of state.

The average cost to move a D6 Dozer across state lines could be between $4,000-$6,000 one way. Not only does this incur extra logistical costs when moving the asset multiple times ($5,000 one way, $5,000 back, $5,000 for a replacement to be dispatched, maintenance costs for the first machine and so on), but it also impacts jobsite productivity in the form of delays (and headaches).

By eliminating the delivery of assets in non-working condition to your jobsites followed by subsequent hauling back to the shop and rental or re-deployment of a replacement asset, you could be saving close to $20,000 per occurrence. This greatly subsidizes the annual cost of your equipment management software.

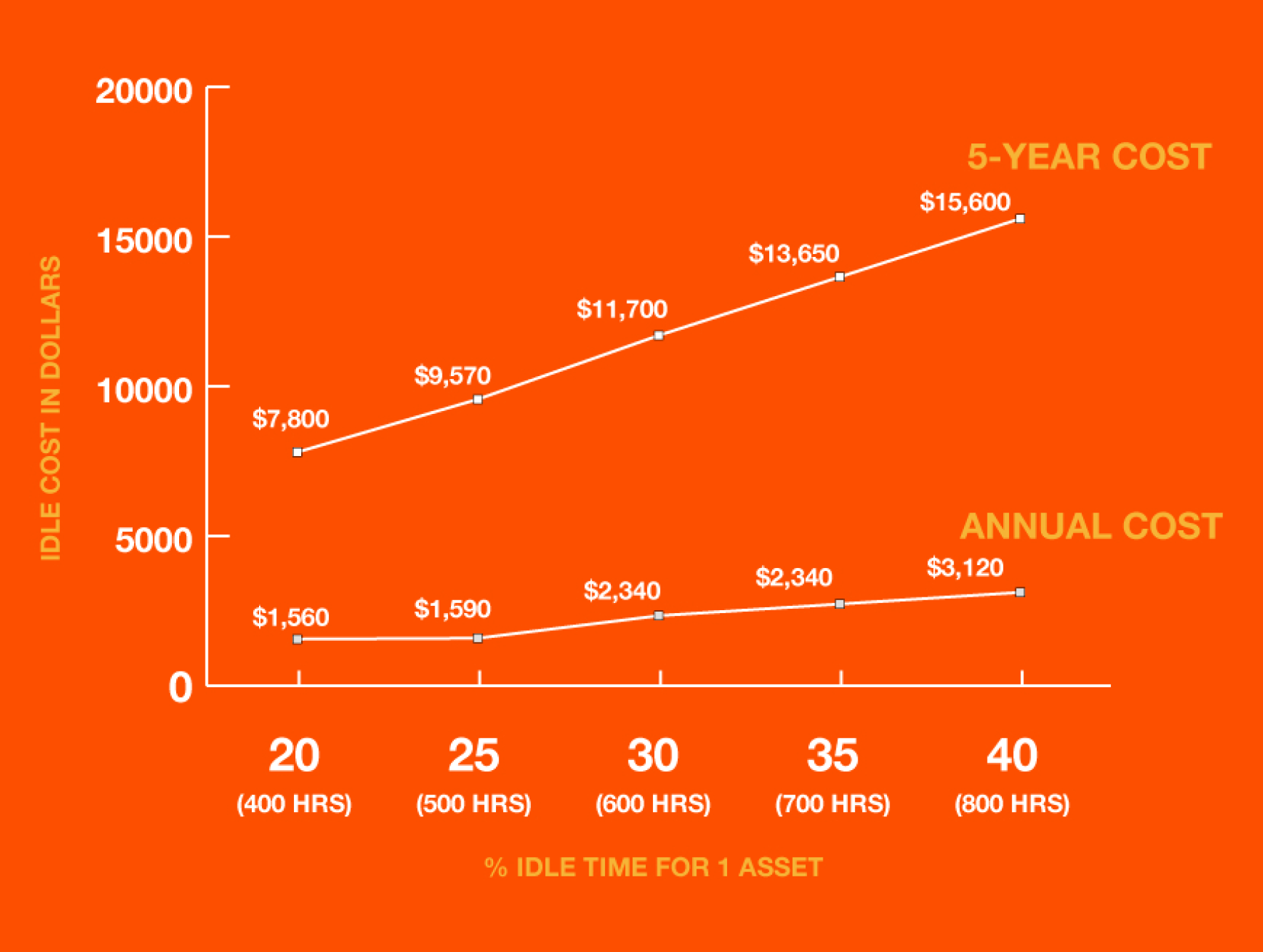

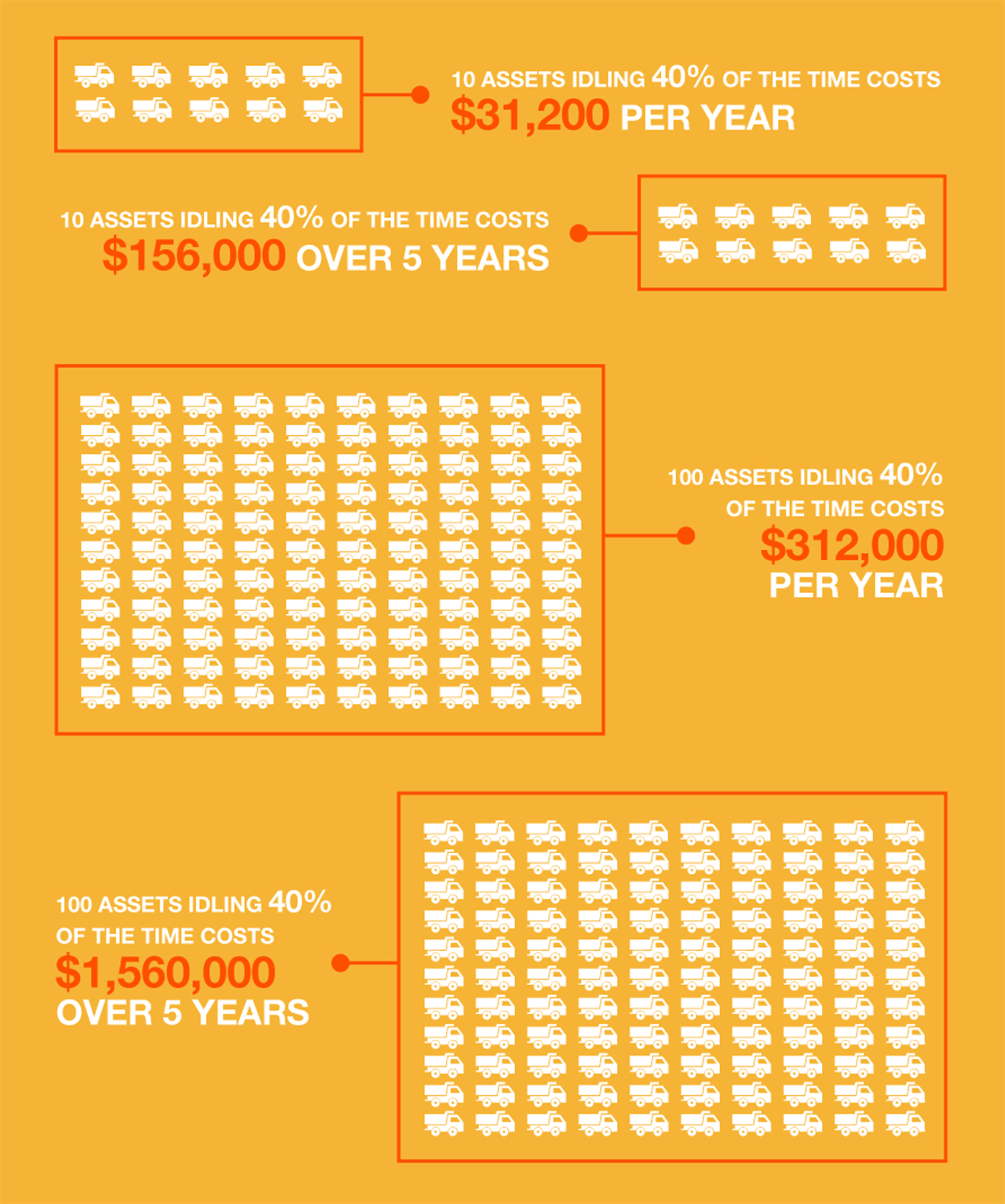

5. Idle Time

If you burn 1.5 gallons of diesel idling per day, per 200 pieces of heavy machinery collectively working 156 days per year, you could be spending over $68,000 in idle costs over the course of a year.

This number can shrink or grow depending on the price of fuel (this example uses $2.91/gal). Not only is it costing you to physically idle your machines, but idle time also prematurely wears those pieces of machinery down. The longer an asset idles, the more the internal components are impacted. Excessive idling could lead to premature engine failure costing you between $20,000 and $40,000 (depending on a heavy vs. light machine).

Using an equipment fleet management technology to identify and curb these practices could recoup these costs for you, which typically more than covers the annual cost of your equipment management system.

6. Accidents

An equipment management system equipped with Driver Safety, DVIR, and Safety & Compliance Inspection features can prevent these on road accidents by monitoring driver performance over time for visibility and improvements towards safer behaviors, as well as verifying that trucks, vehicles and yellow iron machines are in safe and optimal condition for operation prior to beginning an on-road trip or cycle on a jobsite.

If one accident can be prevented by your software, it not only subsidizes your annual software cost, protects your machines and vehicles, and prevents OSHA violation fines and fees, but it also protects your biggest asset – your people.

Conclusion

An important takeaway is that these examples highlight the costs of one single occurrence on each of these fronts during a typical year.

The reality, due to the nature of the construction business, is that these things normally happen on a continual basis across operations throughout the year. Equipment management systems can prevent these circumstances from happening not just once, but many times over, benefiting you with a high return on your investment.

- $30,000 - $32,000 potential savings by eliminating 1 emergency repair!

- $120,000 potential savings by eliminating 1 year of annual finance dues!

- $20,000 potential savings by eliminating 1 unnecessary move!

- $68,000 potential savings by eliminating 1 year of idle fuel waste!

- $21,000 potential savings by eliminating 1 accident!

$260,000 SAVINGS by eliminating just 1 of each x [your experience] = [BIG] financial impact!

The bottom line is that construction is a very competitive business, as well as risky and asset intensive. Tenna provides the ability to manage your equipment fleet more effectively and gain a leg up on the competition for the price of a dozer bottom carriage, and less than the cost of a field engineer.

How Equipment Management Effects the Bottom Line

In construction businesses, the more transparency you have over your assets (people, equipment, tools), the more margin you can earn, more competitive you will be and more profit you will generate.

Equipment management and equipment tracking are economical for construction. It really effects improving logistics and operations which saves you money on active projects, assists in accurately estimating costs, prices and rates for the next job, and drives more efficient and cost effective decision making for the business as a whole.

Equipment management directly effects your bottom line in four simple, but significant ways.

1. Improves Productivity and Progress

Effective management of your mixed fleet allows active projects to meet their schedules and milestones. This improved performance positively impacts your internal organization and elevates your client satisfaction levels.

Giving your employees tools that make their jobs easier boosts their productivity. Reducing the amount of time your employees spend searching for assets, backtracking, making and missing phone calls and other typical inefficiencies greatly contributes to a reduction in wasted time. Eliminating these inefficiencies directly increases the amount of time employees have to get quality work done, which translates to improved productivity. Cost impacts of this are touched on in example four.

Externally, this helps you progress further in your projects faster, which improves your relationships with your clients and could lead to repeat work or reviews and accolades that contribute to the winning of new work. Read more about this in example three.

Internally, equipment management permeates throughout your organization. Used effectively, it reaches employees in all levels and departments in your business beyond just operations. And equipment management system automates data flow between departments and improves communications, overall saving lots of time for all parties.

Not only does this benefit the whole team, but it improves employee attitude and motivation. Motivated and productive employees in the field and in the office are the ones your construction business benefits most from.

2. Provides Insights on Operational Efficiencies and Performance

Equipment fleet management systems provide insights on your assets that were previously unavailable or extremely difficult to back into manually. Analysis of this data can be used to drive improvements and affect change in multiple areas of your construction business.

Performance insights can keep your fleet operational with reduced downtime and elimination of inefficiencies. They can help improve your balance sheet by exposing dead-weight machines that are not working or being used but are continuing to cost you to carry that you can eliminate. Read more about this in example four.

We asked one of our customers we interviewed prior to implementing about how many hours they speculated their wheel loader was working on one project. Their estimate was 2,000 hours, yet the accurate hours logged were 800 hours. The remaining 60% of the time their machine was not in use was wasted. This 60% could have been used on another jobsite to eliminate an unneeded rental or purchase, saving thousands of dollars in costs on a new/stand-in asset and improving utilization on the owned asset.

Overall, equipment management lowers the cost of asset ownership with better equipment utilization and maintenance insights, and helps you better manage costs associated with project variables, including your equipment, labor and inventory.

3. Increases Competitiveness

Accurate equipment utilization data, as touched on in the previous example, gives way to more accurate bid rates. Without accurate utilization data, you provide your estimators with inflated internal costs, which they apply to bids for projects that require similar work. This can, first, make or break a bid, and second, impacts the margin your team will make on that project.

Utilization data provided by your equipment management system can help your operations and estimating teams accurately estimate how long an asset will be needed to perform an operation on a future job.

Further, as touched on in example one, when your customers see you performing efficiently on their projects, it leads to an increase in your client satisfaction rate. Happy customers lead to positive evaluations, awards and accolades to help you qualify for future RFPs and, most desirably, repeat work.

Winning more work grows your bottom line. Increasing your margins and profits with operational efficiencies and informed cost data to underpin bid rates grows that cushion even more.

Equipment management technology is becoming an industry standard. If your competitors are using it already, you are at a disadvantage. Don’t jeopardize your future win rates.

4. Reduces Capital Expenditures

Many of the topics covered in the earlier examples directly relates to a reduction in capital expenditures. Through the elimination of under utilized assets, better preventative maintenance programs that prolong and maximize an asset’s lifespan, and better visibility and accessibility of assets you already own and have available vs. need to rent, efficient asset management significantly impacts a business’ capital expenses.

With equipment resources being one of a contractor’s highest cost centers, better purchase, elimination, rental, and maintenance decisions that can be arrived at from an asset management system’s insight can save a contractor many thousands of dollars each year. With the elimination of one equipment related expense, the equipment management system typically pays for itself. And, in reality, the system eliminates many of these expenses over the course of a year.

The other high cost center for a contractor is labor. With an equipment management system improving daily productivity, work can be completed more quickly and efficiently. Productivity increases while schedule and cost impacts decrease, saving contractors tons on labor costs. When productivity is improved across projects, contractors can better estimate how long it will take to perform routine operations and man hours in future bids; another bid savings and margin buffer. Combined with reduced costs, you grow the bottom line on your jobs and in your business.

An equipment management solution is an investment in your business, rather than another operating expense.

Not only will it bring efficiencies to your operations, but it will also bring about efficiencies in your personnel who directly benefit from what the technology can offer them in terms of less manual work, less re-work, better tools to get their jobs done right, higher productivity, and improved satisfaction and performance overall.

These operational and labor efficiencies (the two greatest cost centers for contractors), combined with insights that help win new work directly translates to your bottom line and the growth of your construction business.

What Doing Nothing May Cost You

Construction technology delivers an ROI for your business in so many ways.

Without incorporating a construction equipment management solution into your operations, you are undoubtedly incurring additional costs that could be easily cut from your bottom line.

Not using a system will cost you on multiple fronts. To illustrate, we’ve assigned a dollar value to eight impacted areas of your business.

1. Inflated Productivity Costs

Technology indisputably saves time. When you, your field managers and crews work more efficiently and optimize your available time, you get more done during that time and costs are therefore decreased for each activity. Without optimizing your time, your productivity costs increase. Wasted time = wasted money.

For example, the project superintendent spends a good part of the day fighting fires when it comes to resources and either emergency needs due to equipment issues or changes in plans which leave them scrambling to find the necessary equipment for tomorrow’s operations.

Having asset data digitally saves both the superintendents and field laborers time as well as your equipment manager’s time, spanning from time on the phone trying to find and coordinate resources to collecting and reporting maintenance information in the field. The savings on doing this digitally vs. manually can be up to 95%. If your field labor costs $30/hour and your laborers spend 15 minutes collecting maintenance information on your fleet of 200 assets, cutting that 15 minutes down to 5 minutes can amount to a $68,400 labor savings. Bake in your management costs and you could find another 20% in gained efficiency in time equating to $65,000 (based on 10 supers, 2 equipment personnel and 5 hours per week on unplanned issues/needs).

2. Reduced Repairs & Equipment Maintenance

The cost of ongoing equipment maintenance, especially on an aging fleet can be draining on your company. Whether you have your own mechanics or outsource repairs, maintenance is a necessary evil, but it can be better managed.

For example, let’s assume you have a mixed fleet composed of 100 pieces of heavy equipment and 100 mid-sized assets (plus a fleet of vehicles and a ton of smaller tools and assets).

If your mechanic labor costs $100/hour, and they spend an average of 10 hours/year maintaining each piece, you spend $200,000/year on mechanic labor. Technology for preventive maintenance and real-time alerts for performance issues can cut 50% from the time mechanics spend on emergency repairs as well as time spent finding the assets, diagnosing issues, getting details from others, etc. This can add up to a $100,000 labor savings.

3. Equipment Acquisition Costs

Without a system to tell you where your equipment and tools are, you likely end up buying or renting assets you couldn’t locate or didn’t realize you already have. Not only would you be paying unnecessary costs to acquire a new asset (the average cost of a wheel loader is $100,000), but your existing asset continues to sit idle burning a hole in your balance sheet while you continue to pay thousands of dollars each month against your loan on it.

With visibility you gain back control and can make more cost-effective equipment moves to improve logistics and increase margins.

4. Disposition Decisions

Without telematics data, you may think it is more cost effective to move an idle asset you already own. But without operational and maintenance data, current condition, and the complete historical cost of owning that piece of equipment at your fingertips, you may not realize that its in fact more cost effective to purchase a new machine for better reliability instead of risking a schedule-impacting breakdown or continuing to pay heavy operating costs to maintain older, less fuel efficient models.

With accurate operational cost data, one contractor was able to identify waste and reduce their mixed fleet by 8% equaling just under $1 million in sold assets. Add in the elimination of ongoing cost of ownership and they were well over $2 million earned/saved.

5. Competitve Edge

Without leveraging the efficiencies brought to you by equipment management technology, you sacrifice the margins you can build into your bid rates that your accurate utilization rates benefit you with.

Say your internal rental rate for a D6 Dozer is $200/ day when used on a project for a month, and you know with certainty from your historical utilization data how much it will cost to move a certain number of cubic yards of dirt based on how many hours the dozer ran when moving this amount in the past. You can use that real cost data accurately in your bid. If you overprice this aspect, you may lose on bid day.

If you underprice it, you pay for that underestimate when the job is underway. Not leveraging your utilization data in your bids ultimately impacts your ability to compete with other contractors who have better control over their operational costs.

6. Schedule Impacts

This one’s a no brainer. Once again, wasted time = wasted money. When man hours are not optimized, or your project is delayed due to resource mismanagement, your schedule starts to slip which has financial consequences. When time is wasted or schedules are not adhered to, you risk getting hit with disincentives or liquidated damages. These come in all shapes and sizes depending on your client but can typically range unlimited from $1,000 to $20,000 per calendar day of delay depending on scopes and milestones.

You also jeopardize any incentives you could receive from your clients for finishing early. This may be a financial incentive, like a $25,000 reward per day (until cap) for completing a critical path scope early, or could come in the form of your reputation, performance evaluations, awards or other accolades that contractors leverage to win future work.

7. Safety Impacts

Not using technology to maintain and monitor your equipment condition and performance can lead to safety hazards for your personnel or breakdowns and recordable incidents against your job sites and business.

These are costly for any injured employees, your schedule, your reputation, your ability to win future work and often involve fines and penalty fees. Today, the average “serious” OSHA violation cost is over $13,000 for one offense.

8. Reduced Profit Opportunities

Improved utilization and increased efficiencies directly translate to your bottom line. Without leveraging these efficiencies, your operational costs such as labor, maintenance and asset acquisition (i.e. unnecessary renting or replacing) will be higher, causing you to leave a lot of money on the table that could be funneled back into your project’s margin and reinvested back into your business.

Revisit the potential cost savings referenced in any of the previous examples. Saving those costs on your jobs increases your profit margin and provides opportunities to redirect those profits later towards other initiatives. When those costs are incurred, your profit opportunities are drastically reduced, or lost altogether.

In conclusion, these are basic costs that in some form apply to all construction businesses. Deploying a construction technology system will help you better control many, if not all, of these impacted areas susceptible to cost creep. A savings in any one of these will amount to a high return for the investment you made to improve your business operations.

How Lost Assets can Cost Your Company Millions

It costs a lot of money to own and operate construction equipment. It costs even more when they idle unnecessarily, break down, or get lost or stolen. Equipment management systems can reduce these costs in 3 critical areas.

Proper care and maintenance of assets can significantly reduce operational costs.

Total Cost of Ownership Over 5 Years: $521,800

(Includes purchase price, insurance, interest and depreciation minus resale value)

Total Cost of Operations Over 5 Years: $1,127,800

(Includes operator wages, fuel, tires, maintenance and repairs)

How Equipment Management Systems Reduce Asset Management Costs

Identifies the location of every asset

Makes it easy to schedule preventive maintenance

Reduces repair costs, which average 5 times more than maintenance costs

Employees are more accountable; take better care of tools and equipment

Keeps assets more organized

Reduces repair costs, which average 5 times more than maintenance costs Reduces amount of equipment lost or left behind on job sites

2. Idle Time

Idle equipment can use up to ONE GALLON of fuel per hour

One hour of idle time every day costs up to $1,000 PER YEAR per asset

Proper care and maintenance of assets can significantly reduce operational costs.

How Equipment Management Systems Reduce Idle Time

Monitors location and performance of equipment 24/7

Automatically tracks idle time (requires plugging into onboard diagnostic port)

Idle time reports make employees more aware of operating costs

Employees become more proactive about shutting down engines when idle

3. Asset Theft

Total industry theft losses estimated at more than $1 BILLION ANNUALLY

Vandalismg and theft cause 1/3 of all equipment loss dollars.

Only 21% of all stolen equipment is recovered.

How Equipment Management Systems Reduce Theft and Vandalism

Identifies location of assets when they were stolen

Improves inventory control

Sends alerts for off-hours or unauthorized equipment movement

Sends alerts when equipment goes outside established Geofence

Total Cost of Ownership

As construction equipment is one of a contractor’s highest cost centers, being cost conscious on your owning and operating costs is critical for equipment owners and managers. All contractors calculate the total cost of ownership (TCO) a little bit differently, with various expenses to consider.

This section covers how certain features in a Construction Equipment Management software

can help gauge and then optimize your TCO.

We observed historical cost data from one contractor over a three-year period to back into an average TCO for a fleet worth roughly $15 million. This was done as part of this contractor’s investigation on how to create goals and establish KPIs integrating a construction equipment management system into their equipment fleet management processes. This customer’s average TCO for the period studied turned out to be $8.7M, which is more than half the value of their entire fleet.

We then analyzed how leveraging the features and functionalities within an equipment fleet management software could directly impact a variety of the cost centers that this contractor uses when calculating their TCO. The following are some examples of how certain equipment management software insights and features directly tie to their TCO and can likely relate to yours.

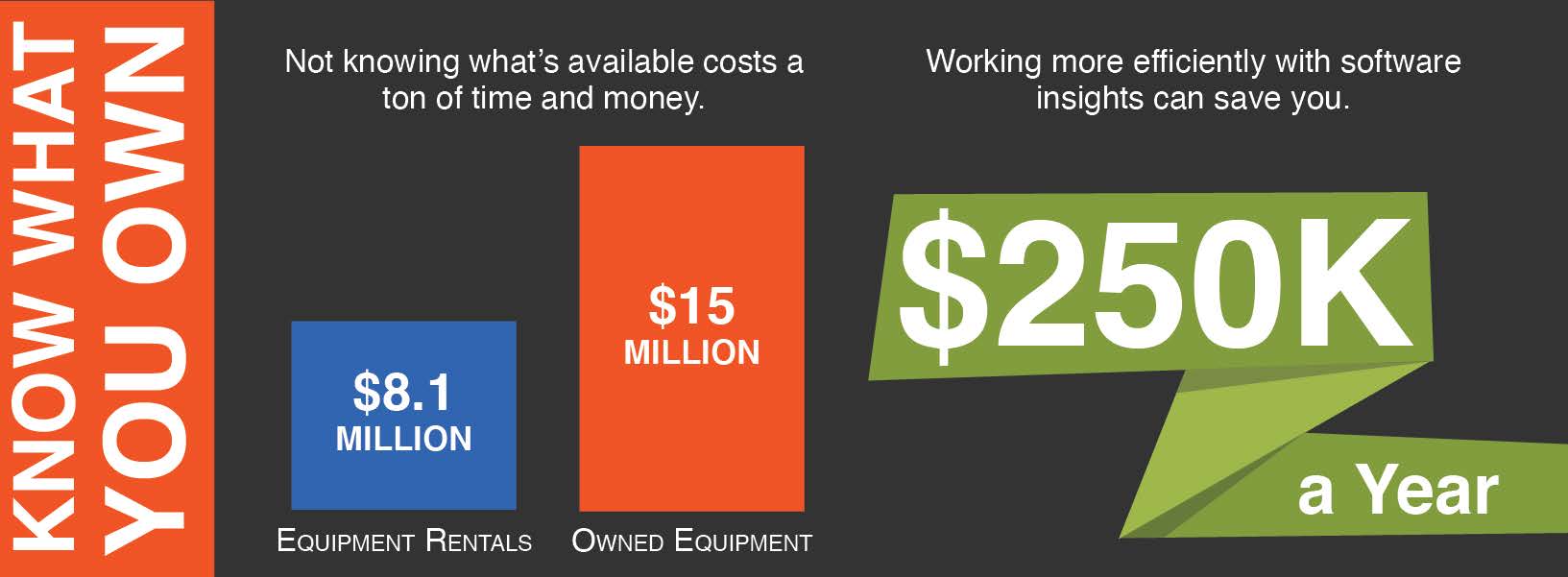

1. Know What You Own

Knowing what you have saves you an incredible amount of time and money. It allows you stay on top of the assets you already own, to be able to produce the right asset for your job, to better utilize, and to get the real value out of your assets that you’ve already purchased. Being able to do this successfully with an equipment fleet management software helps you optimize your assets for the real reasons you added them to your fleet in the first place; helps you improve productivity for your team which contributes to a labor cost savings; and helps you save on rental costs.

Typically, the cost to rent a piece of equipment is $40-$60 per $1,000 that the item costs. That means that renting a $5,000 tool averages about $200 or $300 each month, and a $100,000 machine could cost as much as $6,000 a month. By utilizing an asset you already have, you can eliminate these unnecessary rental costs.

The subject contractor spent a total of $8.1M on equipment rentals over a three year period studied on equipment rentals (an average of $2.7M per year), and that’s already on top of a $15M fleet of owned equipment. They are using an equipment management system to better identify and utilize their owned assets. Working more efficiently with insights from their software, over the next few years this can save them at least $270,000 a year.

TCO Takeaway: Although some contractors strategically choose to rent rather than own necessary equipment, for the companies that do own and maintain the bulk of the assets needed for building their projects, knowing what you have, where it is and when it is available will help you to better utilize and recognize an ROI on your existing assets, while minimizing your unnecessary rental costs.

Related Features: Asset Library, Sites, Geofences, Reservations and Scheduling

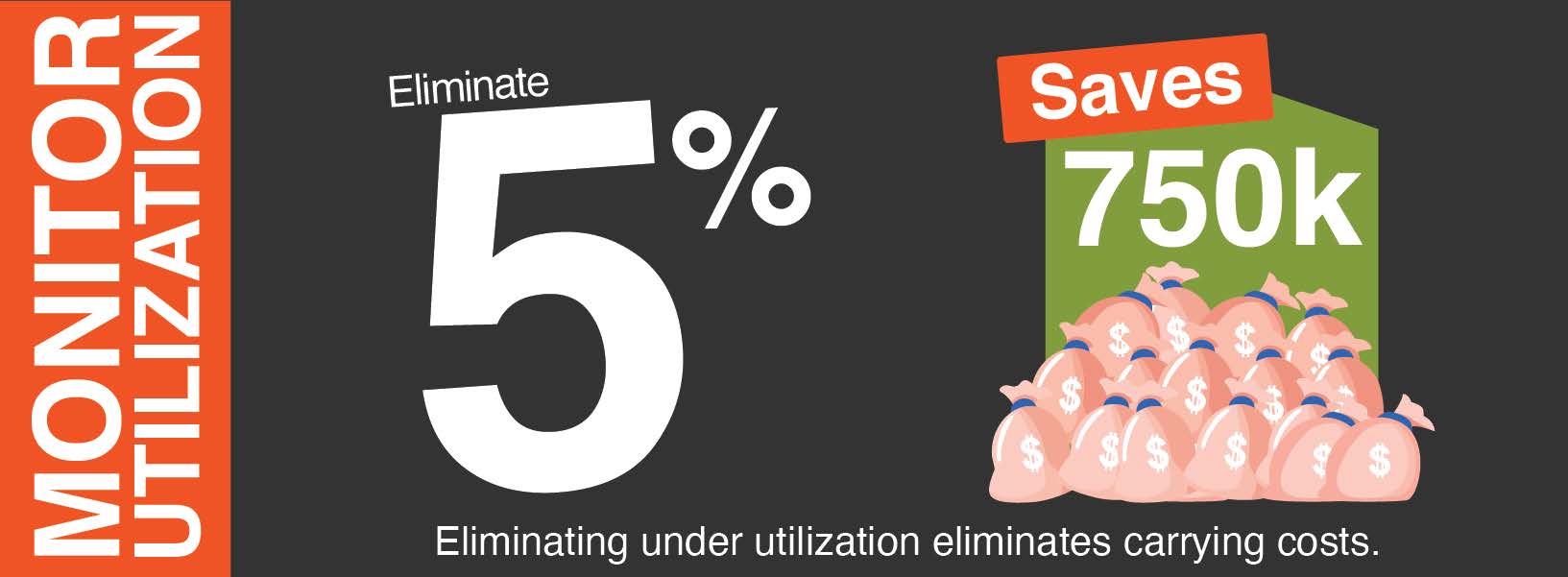

2. Monitor How Often your Machines are Used

It’s important to know the anticipated life of your machines so you can maximize their useful life while you own them. When you integrate an equipment fleet management system with telematics into your equipment tracking and management process, you can use the real telematic data from your machines to check your utilization and measure against benchmarks that you set for each piece of equipment.

When machines are underutilized but being hoarded on a jobsite, you can increase their uptime by relocating them to another jobsite where they are needed a scheduling tool aids in this visibility and efficiency – see the Scheduling section below.

By monitoring utilization, you can determine whether a project team truly needs another machine onsite or if the resources they have are sufficient to complete their required scopes. Our subject contractor had a Superintendent ask for another 100,000-pound excavator for an operation, which would be their fourth similar machine onsite. By looking at the utilization of the current excavators on the project, it was determined that they were underutilized and the project plan was able to be adjusted to more efficiently move the existing machines around site as necessary. The estimated savings for using the available resources vs. outsourcing a rental excavator is $12,000 per month.

When machines are underutilized and truly not needed, it is more cost effective to get them out of your fleet and off your balance sheet. Eliminating just 5% of the underutilized assets in our subject contractor’s fleet could save them $750k in carrying costs. That savings comes off your TCO and bottom line and could be reinvested back into the fleet with a more efficient model of a machine they actually need.

TCO Takeaway: Knowing your accurate utilization can help you better estimate utilization benchmarks and thresholds for other machines and new machines you add to your fleet to help maximize their useful life and earn you an ROI based on your ownership and operating costs. Knowing your true utilization helps you maintain the size of your fleet appropriate to your operational needs.

Related Features: Utilization, Reserve It, Asset Library

3. Properly Maintain your Machines

It’s obvious that repairs and routine maintenance amount to a high percentage of your owning and operating costs. Effective maintenance extends your asset’s lifespan, improves performance and reliability, increases your ROI on your owned assets and helps reduce or slow depreciation. Automated maintenance customized for your specific fleet by your team using your equipment management system keeps preventive maintenance automated based on your defined triggers, so maintenance needs are always visible and scheduled for your mechanics.

With efficient maintenance, repairs caused by poor maintenance and/or neglect are reduced, lowering unnecessary costs. It also helps avoid unplanned downtime which has direct impacts on your jobs – when your jobs lose money because of a machine, you eat at your margins.

The more maintenance your machines need because of inefficient use or excessive wear and tear, or frequent use outside of “normal working conditions” the higher your parts and labor costs will be. Our contractor paid an average of $3.4M in parts, supplies and labor over the three-year analysis. This included an average of $1.1M for outside labor needed for specialty repairs.

Drilling down further into this number, it cost $9,800 to replace the rubber tracks on a John Deere 470G Excavator (including the rubber track parts and associated labor). Replacing tracks on heavy machines such as excavators, dozers, cranes, etc. also requires the replacement of the rollers, slack adjusters and other components of the complete undercarriage. It cost this contractor $22,000 total for the total track replacement on this single machine.

Based on this contractor’s numbers, leveraging an equipment management system to improve their equipment maintenance can cut an easy $110,000+ from their ownership costs, as efficient maintenance reduces external repair costs. It is also more cost effective to perform in-house maintenance routinely at appropriate intervals while using your own labor rates and leveraging the staff mechanics already on your payroll.

In addition, record keeping of your maintenance activity history in an equipment management system helps improve your equipment’s resale value – just by having these records, or a report you can produce with this data, you can prove that the machine was well maintained and in good working condition when its time to sell.

TCO Takeaway: Staying on top of your preventive maintenance can drastically improve your equipment functionality and extend the useful life of each machine while minimizing excessive repair costs which weigh down your TCO.

Related Features: Maintenance

4. Schedule the Assets you Need, When you Need Them

Seeing how frequently some machines are requested more than others by your jobsites can help make sure you always have the right machines for the job in your fleet.

This helps to ensure that your machines are getting adequate uptime, are being scheduled for maintenance when appropriate, and aren’t being hoarded and hidden on projects instead of being better utilized elsewhere.

Revisiting the rental cost example discussed within the Know What You Own section, with better visibility, scheduling and coordination of owned resources between jobsites, much of our subject contractor’s $2M rental spend could have been reduced. Using the average $6,000/month cost for a $100,000 machine, they could save $18,000 by using an existing asset from their fleet for a 3-month operation on one of their projects in the future.

For example, this contractor had a case where a project needed a 3-wheel sweeper onsite and the Superintendent was unaware one was sitting idle on a nearby project. This Superintendent contacted a local rental house they had a relationship with; when the Equipment Department realized the rental sweeper was reserved, they were able to cancel the order and move the company-owned machine to the project, saving $1,500/month and improving utilization on the owned asset and bringing income to the Equipment Division.

Additionally, recalling the cost examples within the Monitor How Often your Machines are Used section, having visibility into which assets are being requested and utilized more than others may shed light on opportunities to eliminate assets from your fleet instead of continuing to pay carrying costs on machines you aren’t using or aren’t earning you anything.

TCO Takeaway: Knowing what you have available and maximizing the utilization of your owned assets impacts excessive rental costs and helps you optimally use the assets you are already carrying on your balance sheet.

Related Features: Reservations, Sites and Geofences, Utilization

5. Monitor your Fuel Consumption

All your engine-operated assets need fuel to run. Fuel is costly to begin with based on industry prices and your level of use, but it can also be more costly than necessary based on operating behaviors.

Recognizing your idling behaviors using telematics data from your machines interpreted by your equipment fleet management software and curbing this practice in the field can help get a handle on operating costs and increase resale value. If you stop burning unnecessary hours on your machines, you’ll naturally also stop spending excessive amounts in fuel costs.

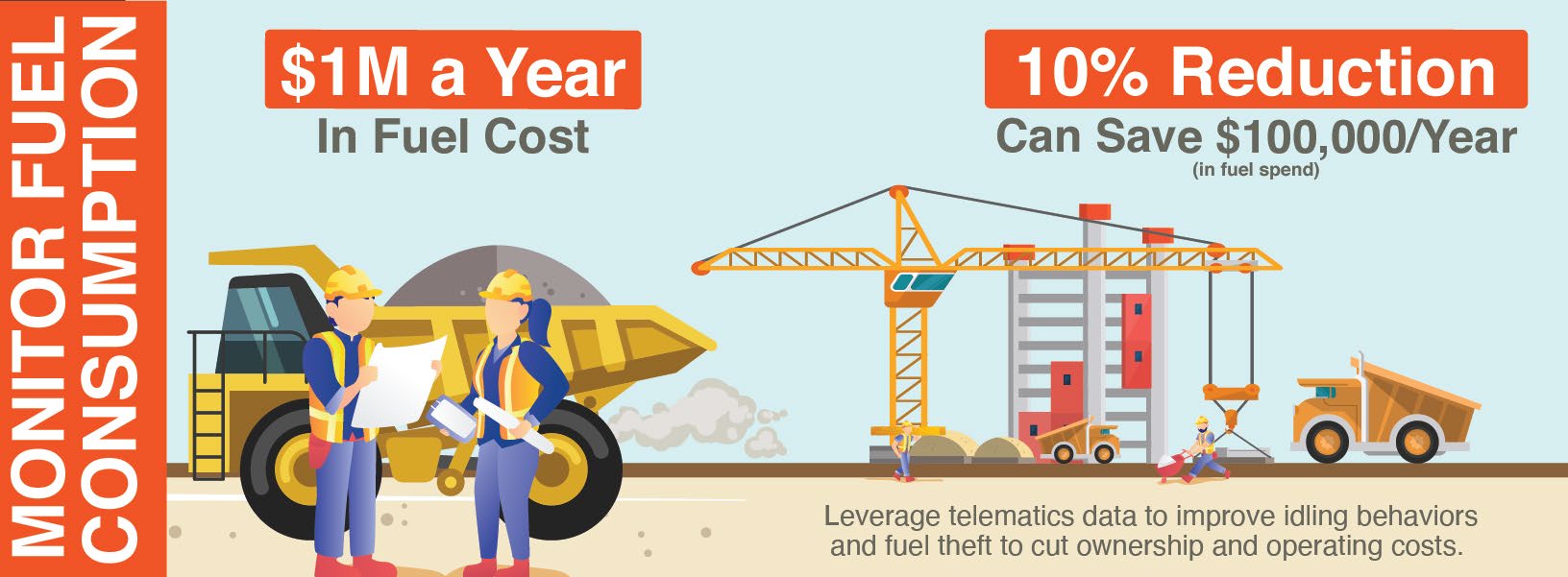

Our subject contractor spent over $1M a year (based on the three-year average) on fuel costs. A 10% reduction in fuel spend thanks to monitoring their idling with a telematics system could save them $100,000 a year just in fuel!

Reducing your idling costs additionally helps lower your maintenance costs. Reducing the amount of idling on a machine directly reduces the amount of maintenance needed on it instead of inflating the number of operating hours racked up by idling. The more hours you rack up on a machine, the more frequently maintenance is needed. If you have two machines that run for 1,000 hours and 500 hours respectively for the year, and Machine A idles at 50% while Machine B idles at 25%, Machine A will rack up 25% more hours than Machine B. Over a three-year period at these same idling levels, Machine A’s fuel costs and maintenance costs will be exponentially higher than Machine B’s – resulting in significantly higher ownership costs for Machine A overall in addition to a reduced resale value – all because of idling.

Excessive idling can also cost your company in wasted warranty dollars. If you are running newer equipment with a factory warranty remaining or an extended warranty contract, excessive idling can waste valuable coverage and be a cause for a manufacturer to deny warranty coverage for potential repair costs.

Leverage idling data from your equipment trackers to improve your idling behaviors in the field – your analysis of this data could reveal that idling is specific to certain operator assignees or could be a result of not using the right machine(s) for the job.

Using fuel consumption data from your equipment trackers and integrating your fueling processes with a fuel card system that monitors fuel consumption and costs at the pump can also highlight instances of fuel theft which is an unfortunate reality in construction and is an area of fuel cost creep.

TCO Takeaway: Whatever the cause of it, curbing your idling will cut your ownership costs. Leveraging telematics data to get a handle on your idling behaviors and curbing fuel theft can have a tremendous impact on your TCO.

Related Features: Fuel, Maintenance

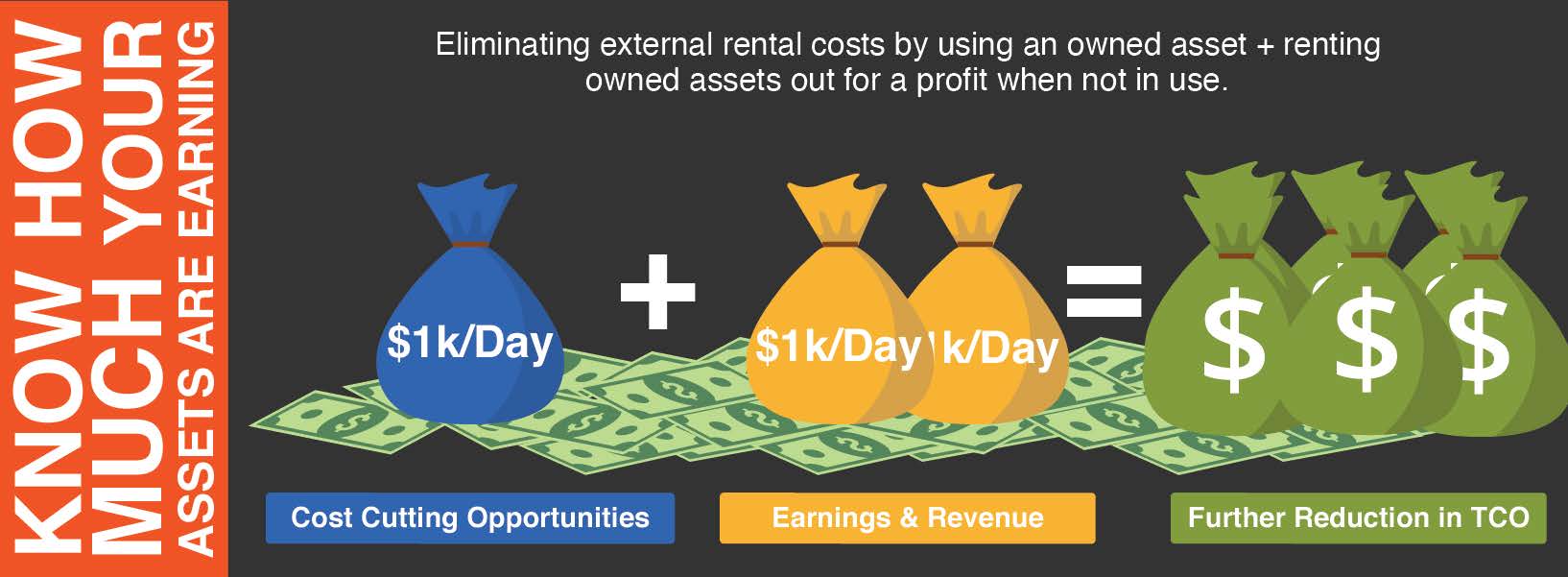

6. Know How Much your Assets are Earning

Knowing how much your assets are earning for you both internally on your jobsites and outside of your organization helps to offset your ownership and operating costs. Using an equipment management system to aid in effective project planning can help determine what equipment is available for project needs and what owned machines can be utilized to bring income to the Equipment Division vs. paying cash to an outside company for a rental. Further, choosing to leverage an RPO option on an external rental based on knowing what is already reserved in your fleet and what machines may be needed long term helps make smart financial decisions when acquiring a needed asset.

As an additional benefit, having your financial information available at the asset level can help you keep the big picture of your equipment finances visible to you. With this visibility, complete with full data integrated with your ERP systems, you can make sure you are staying on track and making smart financial decisions to stay in line with your budgets or savings and cost control goals.

Visibility across current loan balances, interest rates and terms for all loaned or leased assets can help make decisions on which machines to pay off sooner than later if its costing more per month or year than another machine or package of equipment.

Our contractor paid an average of $301,000 on interest over a three-year period for their $15M fleet. A savings of just 10% due to effective negotiating or alternative financing could save them $30,000 a year.

TCO Takeaway: Having your cost and earnings information automated and available can help you identify when costs are being exceeded or find opportunities for cost cutting or earnings to balance out your TCO.

Related Features: Asset Revenue, Finance Tools

7. Inspect your Equipment Before Use for Safe Performance

Even with perfect maintenance, the construction environment is rough on equipment and damage is sometimes unavoidable. Equipment inspections help identify when something is amiss with a vehicle or machine and can keep the focus on safe and optimal performance. When an issue is discovered during an inspection, a fix can be identified and taken care of quickly, before the issue or condition becomes worse or results in a costly and avoidable safety incident.

Equipment inspections may also sometimes shed light on operator misuse which can become very costly in terms of machine maintenance and repairs (repairs can cost thousands of dollars and eliminating them can save hundreds of thousands). For example, our subject contractor experienced stick damage to a CAT 305 caused by an operator not removing a socket from the bolt on a manual quick coupler. Because the socket was stuck and unable to be removed, the contractor incurred a $400 hit to repair the damage, as well as two lost days of rent at $323.04. In addition, productivity was impacted and the crew needed to be moved into new operations during the repair downtime.

Properly inspecting this machine prior to operation would have avoided this incident. By more consciously operating equipment safely, you can reduce the amount of wear and tear, but especially costly repairs that are needed.

In addition, by integrating an equipment tracking and management system into your business with documented safety and maintenance inspections, you may be able to reduce your insurance premiums. Insurance companies need to trust that you are operating and maintaining your equipment safely to provide cost-appropriate coverage for your business.

Our contractor spent a combined total of $2.1M in vehicle and equipment insurance over the three-year period studied (an average of $716k for each year). Having a proven equipment tracking program complete with inspection and maintenance monitoring, tracking and recording can lower your insurance premiums by providing documented evidence of proper asset use and care which provides insurance agencies with trust and confidence. A 10% impact on your premiums can reduce our customer’s total cost of ownership in terms of insurance by an average of $71k annually.

TCO Takeaway: Lowering your risk of malfunction and safety issues while lowering your insurance premiums is a double cost benefit for your TCO.

Related Features: Safety & Compliance, Inspections, Driver Scorecards

Conclusion

What this means for our contractor:

This contractor, who spends an average of over $8.7M owning and operating their fleet each year (including rental costs caused by operational inefficiencies), could save close to a million dollars a year at a minimum by leveraging the features and functionality in their Tenna account in the ways described herein for just a 10% improvement in efficiency. With a little bit of data accumulation and practice using and leveraging the system over time as it becomes part of their team’s daily routines, their savings potential is enormous.

What this means for you:

When you leverage an equipment management system in your fleet, you will also benefit with high savings from efficiencies. What you do with this savings or how you invest it back into your business will be different for each contractor reading this – but know that the savings are real and the costs and effort to actualize them is low in comparison.

Leveraging a construction equipment management system, you can make better buy/move/rent/sell decisions, in addition to improving operating and maintenance efficiencies to help you reduce the owning and operating cost of your fleet.