Construction Equipment Tracking Spreadsheet [Free Template]

- Craig Vivier

- May 29, 2025

Your $400,000 John Deere 350 excavator is sitting idle at one site, and instead of using it, you’re spending $9,000 to rent the exact same machine on another site that’s only an hour away.

This scenario plays out daily across construction projects because most contractors are flying blind when it comes to equipment management. You know that dozers, excavators, and loaders are moving between sites, but without real-time visibility, you’re constantly playing an expensive game of hide-and-seek with your own assets.

The frustration goes beyond just location tracking. You’re dealing with unexpected breakdowns that halt critical path work, equipment sitting unused while rental bills pile up, and maintenance schedules that exist only in someone’s head (and then that person goes on vacation). Each of these problems chips away at your profit margins in ways that are hard to quantify but impossible to ignore.

Here we’ll provide a free construction equipment tracking spreadsheet template that gives you immediate visibility into your fleet, plus show you how leading contractors are moving beyond spreadsheets to systems that actually prevent these costly scenarios from happening in the first place.

Downloadable Template – Construction Equipment Tracking Spreadsheet

We’ve put together a simple equipment tracking spreadsheet specifically for construction:

A Better Way to Track and Manage Your Equipment

While spreadsheets are free and easy to use, they’re not always an ideal option for equipment management and tracking for a fleet size beyond the single digits. They often have issues like:

- Requiring Manual Updates: Every hour-meter reading, status change, location move, and maintenance note has to be entered manually. This takes valuable time and is prone to error.

- Lacking Real-Time Location and Service Alerts: A spreadsheet won’t alert you when a skid steer hits its 250-hour service or when a compressor disappears from Site B. There’s no automatic reminder for safety inspections, DOT compliance, or annual certifications, so you may miss important dates.

- Becoming Unmanageable as the Fleet Grows: If you’re managing just five assets, a spreadsheet can work. But managing 50+ machines (excavators, pickups, light towers, attachments) across multiple projects becomes chaotic. Plus, you can’t track mixed service intervals (hours, miles, calendar days) side by side without endless tabs and lookup errors.

- Lacking Reporting and Visibility: Need to spot your costliest dozer, see which generators sat idle 60% of last week, or prove utilization for job costing? Spreadsheets force you to sort, filter, and build pivot tables. They’re not the same as real-time dashboards and automated analytics.

This is where a complete construction equipment tracking solution like Tenna can significantly improve the way you manage your equipment.

GPS Tracking and Geofences

Unlike spreadsheets, Tenna provides GPS tracking and geofencing capabilities. Tenna’s GPS trackers provide real-time updates when equipment moves between jobsites or leaves approved areas. These include:

-

- TennaCANbus: Hardwired tracker that taps directly into equipment engines to capture idle time, fuel consumption, battery levels, and engine diagnostics

- TennaCAM 2.0 Heavy Equipment: Dual-facing camera that delivers 360-degree visibility around heavy machinery to reduce blind spots and improve jobsite safety (pairs with TennaCANbus)

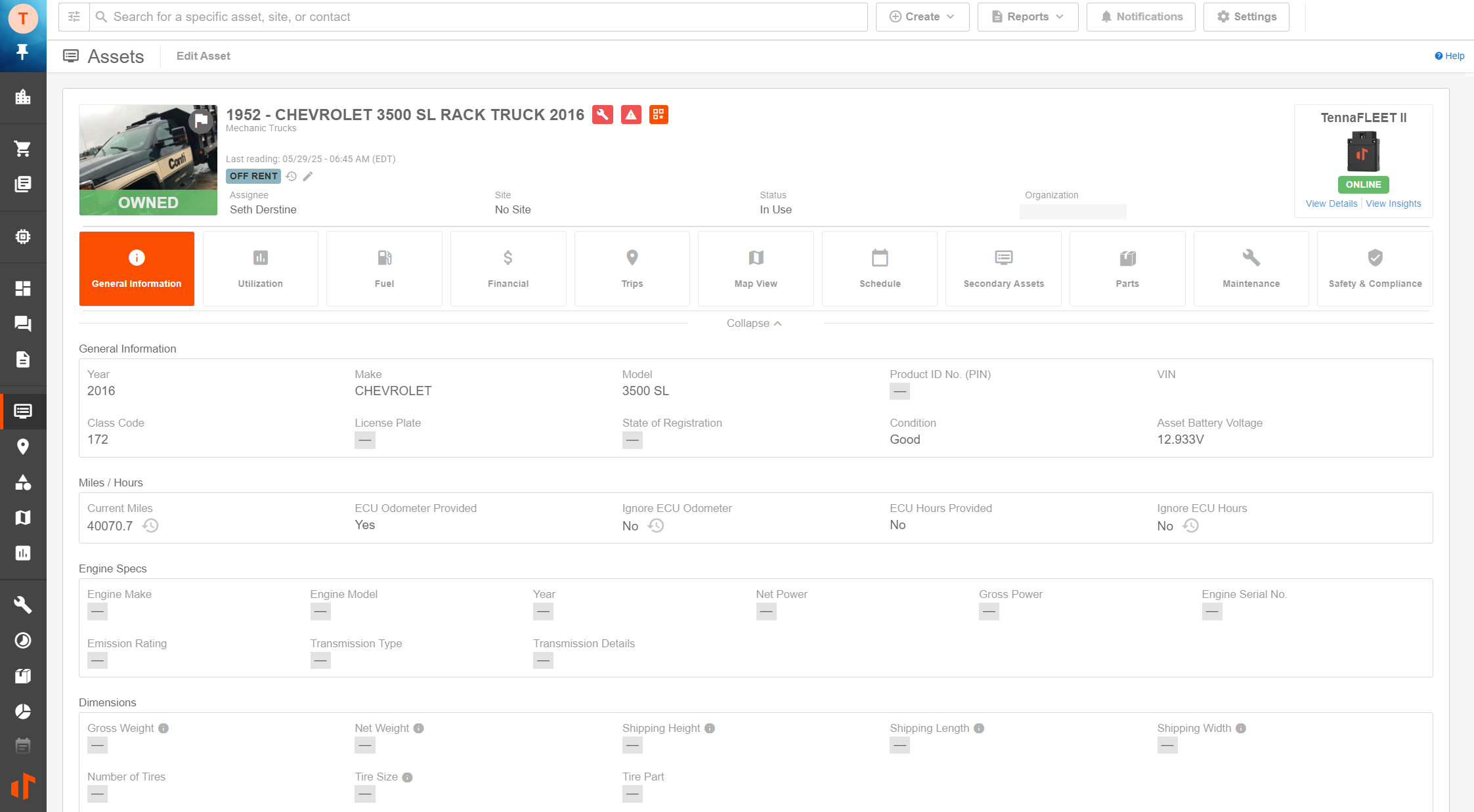

- TennaFLEET II (OBD II and JBUS): GPS tracker that pulls location, speed, engine hours and other diagnostic data directly from vehicle Engine Control Units

- TennaCAM 2.0 Fleet: Dual-facing AI dash camera that monitors and provides alerts on driver behavior and captures incident footage for safety protection (pairs with TennaFLEET II)

- TennaINTEL: Tracks heavy to mid-sized equipment with or without engines while detecting Bluetooth signals from nearby attachments, tools and miscellaneous support assets affixed with TennaBLE beacons

- TennaMINI: Monitors valuable equipment with or without engines with solar charging for extended operation in remote locations

Geofencing turns these trackers into virtual security guards around your job sites, storage yards, and equipment locations. Instant alerts notify you when assets cross boundaries you’ve drawn on the map, catching potential theft while automatically updating equipment locations.

Utilization

Tenna prevents equipment hoarding by offering full visibility into asset utilization across all sites, ensuring efficient resource allocation. Tenna’s hardwired trackers pull actual runtime data directly from equipment engines, measuring performance in real hours and miles instead of rough estimates. You set the utilization benchmarks that match your fleet size, types and current workload, then spot underperforming assets at a glance.

The system reveals exactly how your equipment performs across different projects and time periods. Compare similar machines, identify productivity patterns by location, and use this data to make smarter decisions about scheduling, rentals, and equipment purchases.

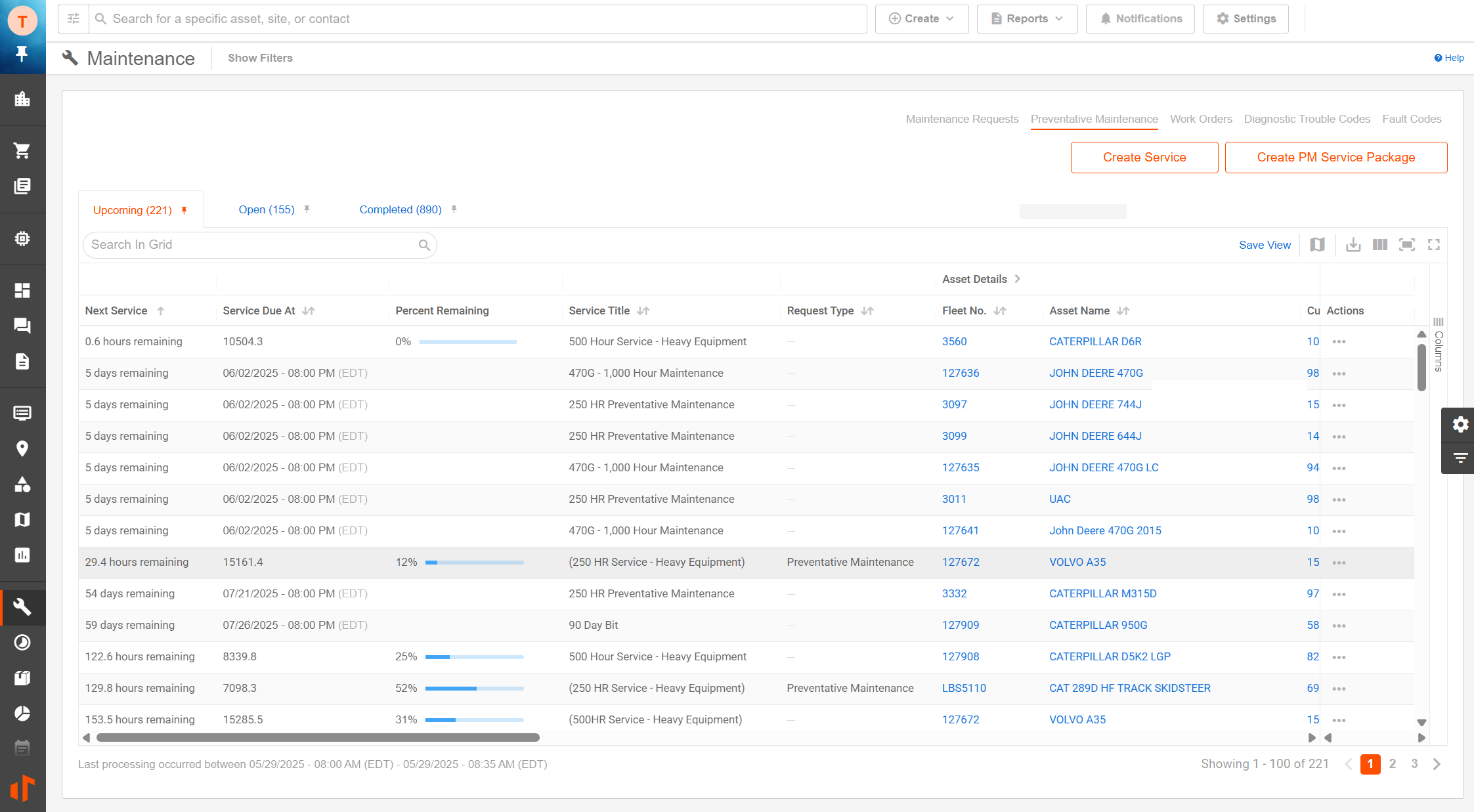

Equipment Maintenance

Tenna tracks actual engine hours, mileage, and calendar time to trigger preventative maintenance alerts exactly when your equipment needs attention or when service is coming due. Your heavy-use machines get more frequent service while idle equipment intervals can be adjusted appropriately.

Field crews can submit maintenance requests instantly through the mobile app using voice memos and photos. Every repair gets documented with parts costs and labor details, building a complete maintenance history that protects warranty claims and boosts resale value.

Mobile App

Your equipment doesn’t stay parked at the office, so why should your management system? Tenna’s mobile app puts complete asset control in your pocket, working anywhere your crews operate. The app stores critical data locally via offline mode, so equipment information reports from the field even when cell towers can’t reach remote job sites.

Instantly pull up any asset’s location, maintenance history, and current status in the Tenna app from anywhere. Submit work orders using voice-to-text and photo capture, request equipment transfers between sites, and update asset records to eliminate paperwork and phone tag with the office.

What to Track in Your Construction Equipment Tracking Spreadsheet

If you’re not ready for a digitized solution like Tenna just yet and you want to continue tracking your equipment manually in a spreadsheet, here’s what we recommend including:

Asset ID

Asset ID

Assign a unique identifier to each piece of equipment in your fleet. This becomes your primary reference point for all tracking and connects between physical assets and your records.

For easier identification and sorting, use a consistent numbering system that incorporates equipment type codes. For companies with multiple divisions or locations, include location codes within your asset IDs to quickly identify where equipment originated. Choose an identifier that is also recognizable within your ERP/accounting system.

Category Type

Category Type

Categorize your assets by function (heavy equipment, heavy truck, mid-sized asset, etc.) This classification helps organize your fleet and lets you analyze equipment usage patterns by category.

It also simplifies equipment assignment when you need specific types for certain jobs. Creating standardized equipment type categories also makes reporting more accurate, especially when comparing utilization across similar assets.

Make/Model

Make/Model

Document the manufacturer and model of each asset. This information is crucial for maintenance requirements, parts ordering, and replacement planning.

Knowing exact specifications ensures that you compare similar equipment when analyzing performance across your fleet. Include enough detail to distinguish between similar models with different capabilities, since this affects which jobs they can perform.

VIN/Serial Number

VIN/Serial Number

Record the manufacturer’s VIN or serial number for every asset. This unique identifier proves ownership and helps with warranty claims. Plus, it’s essential for resale or recovery if theft occurs.

The serial number also helps prevent duplicate entries that can hurt data accuracy in your ERP.

Purchase Price

Purchase Price

Log the original cost of each asset to track your capital investments. This baseline figure simplifies depreciation calculations, helps determine total cost of ownership, and informs future purchasing decisions. Include any significant attachments or modifications in this figure.

Purchase Date

Purchase Date

Document when your company acquired each piece of equipment. This date helps track asset age, calculate depreciation, and plan for replacement cycles.

Older equipment typically requires more maintenance, so this date helps predict increasing service needs. This date also serves as the starting point for warranty periods and helps determine when equipment might be due for replacement based on your company’s asset lifecycle policies.

Ownership Type

Ownership Type

Specify whether you own, lease, or rent each piece of equipment. This distinction affects financial reporting, maintenance responsibilities, and availability planning.

Current Location

Current Location

Track where each asset is currently assigned. This important information prevents equipment hoarding on specific jobsites and helps improve resource allocation. Update this field during check-out and check-in processes to maintain location accuracy. However, keep in mind this is unscalable and often immediately inaccurate without automation.

Consider adding fields for planned future locations. Include dates to improve scheduling and resource allocation across projects, creating a level of visibility into equipment movement.

Status

Status

Indicate whether equipment is available, in use, under repair, or scheduled for maintenance. This status field prevents scheduling conflicts and helps manage workflows by showing which assets can be deployed immediately.

Consider using color coding to make status changes instantly visible. Include notes on any operational limitations for equipment that’s available but restricted to certain use cases due to minor issues that don’t require immediate repair.

This requires a lot of trust and diligence to keep up to date in a spreadsheet, which is another reason why contractors turn to software to automate and manage these workflows.

Hour-Meter

Hour-Meter

Record operating hours for each piece of equipment to guide maintenance scheduling and evaluate equipment utilization. Regularly updating hour-meter readings gives you insight into how heavily equipment is being used and enables accurate service interval planning.

Consider creating additional columns to track hours between services and flag assets approaching maintenance thresholds. This helps prevent unexpected downtime on critical projects.

As you can see, a lot of these tasks for updating and maintaining a spreadsheet are extremely time consuming and tedious.

Ready to ditch the spreadsheets and digitize your equipment tracking and maintenance workflow? Reach out to us today.

About Craig Vivier

Craig Vivier is a results-driven Regional Account Executive at Tenna, bringing a proven track record of success in sales and business development. With deep expertise in driving revenue growth and expanding market presence, Craig consistently exceeds performance goals through strategic new business acquisition and strong client relationship management. He is known for his innovative approach to sales, ability to penetrate existing markets, and skill in elevating brand awareness. Craig is also a strong communicator and leader, with a talent for building high-performing sales teams and delivering impactful presentations and negotiations