Driver Vehicle Inspection Report (DVIR)

Simplify and Streamline DVIR Compliance with Tenna

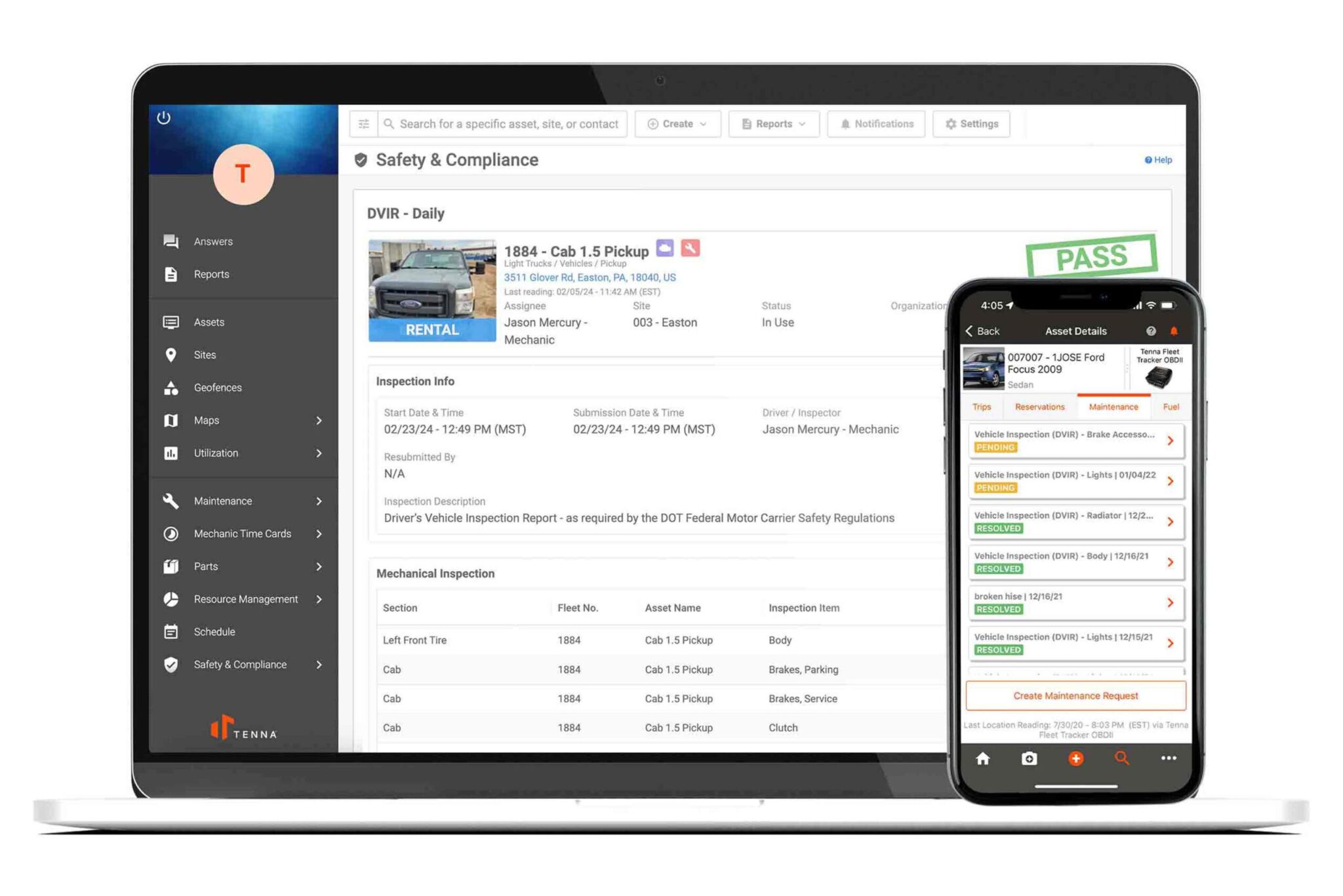

Maintaining roadworthy vehicles and complying with FMCSA regulations doesn’t have to be a burden. Tenna’s Driver Vehicle Inspection Report (DVIR) solution empowers construction fleets with a seamless, digital platform for daily vehicle inspections—reducing paperwork, streamlining compliance, and keeping your fleet safe and operational.

Part of Tenna’s Safety and Compliance software, Tenna’s driver inspection tool ensures drivers and fleet managers have the visibility, accountability, and efficiency they need to meet safety requirements and minimize costly vehicle downtime.

The Benefits of Going Digital for Inspections

Reduce Risk and Liability

Identifying and addressing defects before they cause an accident protects your drivers, your equipment, and your reputation.

Streamline Communications

Automatically connect field and shop on inspection outcomes, avoiding the need for phone calls, emails, spreadsheets and more.

Improve Accountability

Track who performed each inspection, when, and what issues were noted—all from a single dashboard for greater visibility over operations.

Maximize Equipment Uptime

With quicker defect detection and fixes, your vehicles stay in the field longer and spend less time in the shop. This helps lower operating costs.

Lower Insurance Costs

Reduce insurance premiums with documented safety tracking programs as well as an improved safety record.

Empower Your Field Teams

Drivers appreciate easy-to-use tools. With Tenna, they can spend less time on paperwork and more time getting the job done.

With Tenna’s DVIR feature, Viking Construction can now log all its inspection reports electronically. This saves drivers time and helps prevent small mechanical issues from becoming significant problems.

Why Construction Fleets Need a DVIR Solution

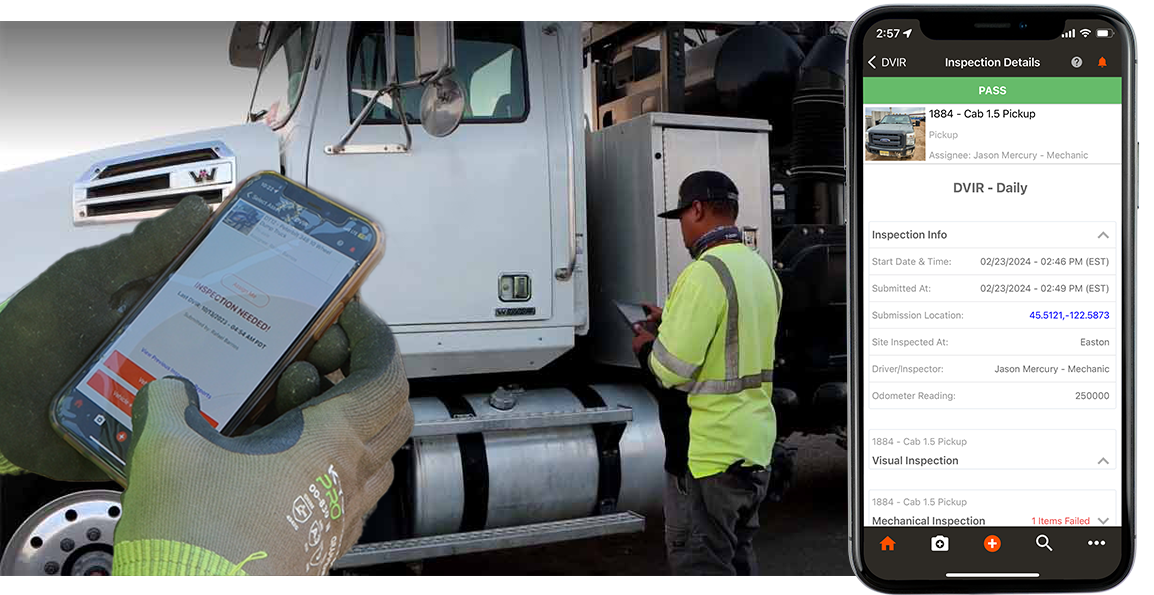

With Tenna’s driver inspection tool made for construction, your drivers easily can perform inspections on any mobile device. Maintenance teams get real-time updates on flagged issues—no delays and no lost paperwork.

Common Challenges Solved:

- Delayed or missed inspections due to paper-based processes

- Communication breakdowns between drivers and maintenance teams

- Missed defects resulting in unsafe vehicles or compliance violations

- Disorganized records during DOT audits or internal reviews

Key Features of Tenna’s DVIR System

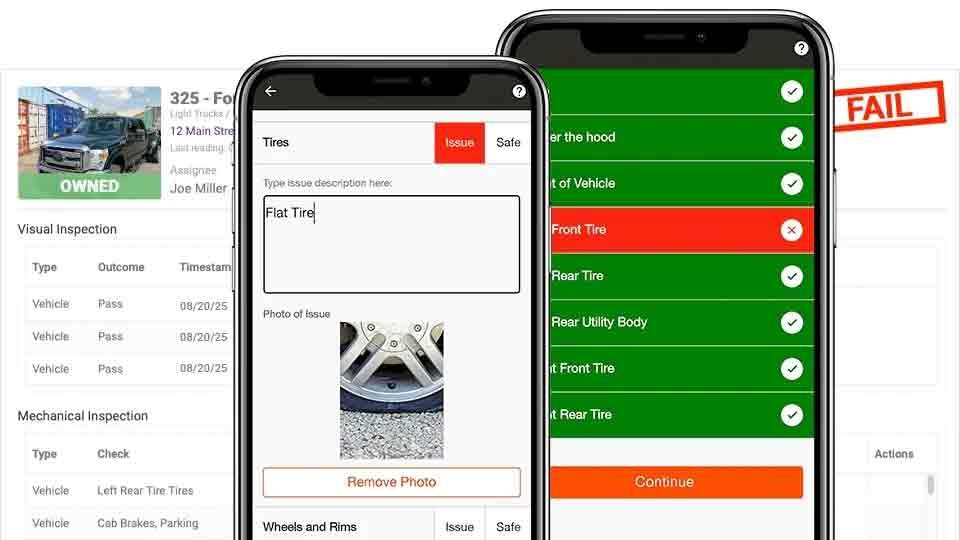

Tenna’s mobile-first design makes it easy for drivers to complete and submit vehicle inspections from their phones or tablets—no clipboards, no chasing signatures, just workflow shortcuts and an intuitive experience designed for folks on the go.

- Pre-trip and post-trip inspection workflows

- Customizable inspections checklists for different vehicle types

- Photo capture for defect documentation

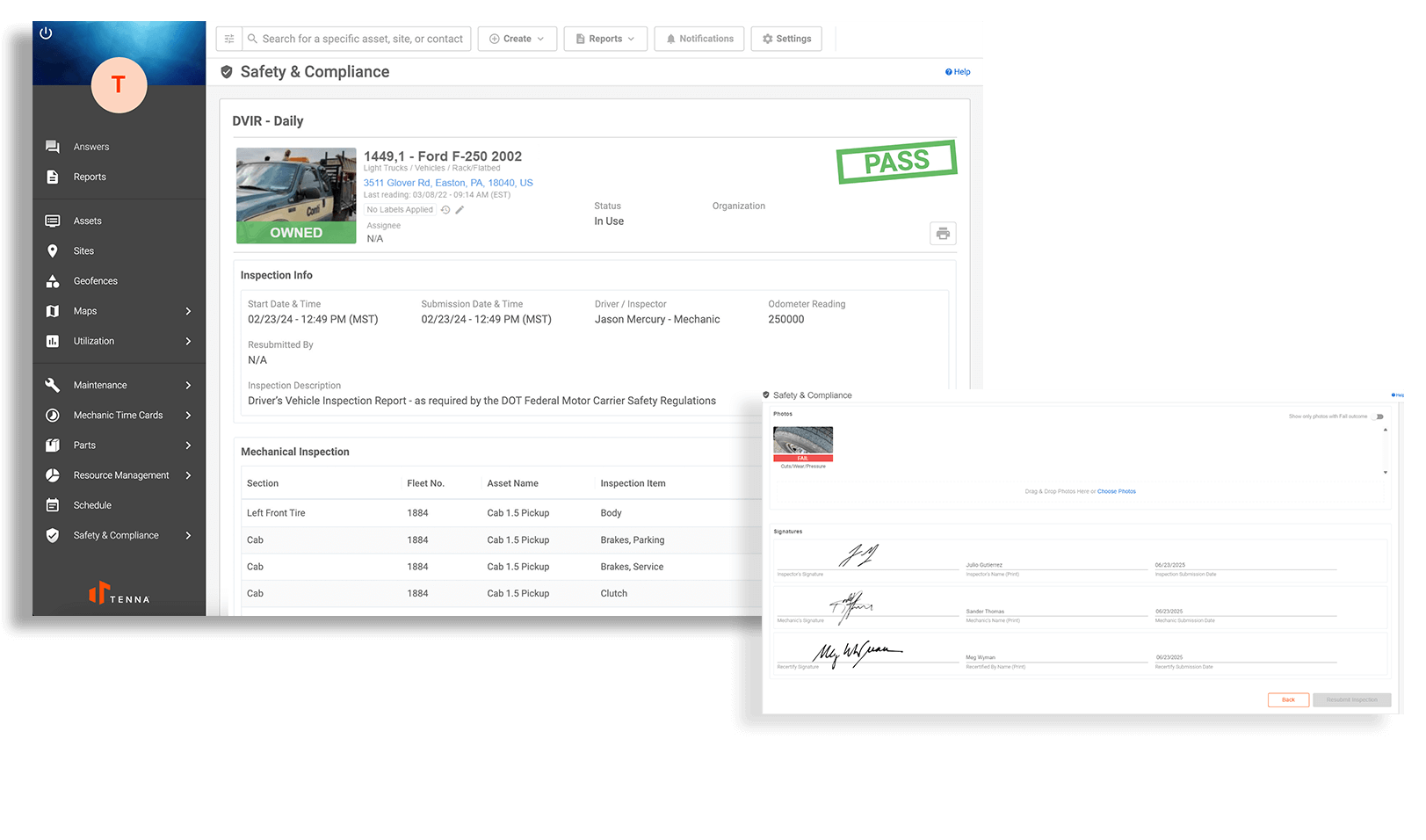

- Electronic signature collection

- Optional visual inspection plus automatic location and time tracking using QR codes to ensure accuracy and avoid pencil-whipping

Inspection issues flagged by drivers immediately alert your maintenance team. No more waiting until the next shift to find out about a brake problem or tire issue.

- Instant notifications of failed inspection criteria to maintenance managers

- Detailed defect logs tied to asset records

- Prioritization and automated maintenance request generation

Inspection logs are stored securely in the cloud, with timestamps, signatures, and audit trails that meet DOT compliance standards. Customizable elements allow DVIR inspections to fit your unique fleet.

- Secure, searchable records for all inspections

- Easily access during audits or roadside inspections

- Reduce risk of violations and fines

- Resubmit fixed issues and recertify vehicles post-repairs to stay compliant while minimizing paperwork and manual coordination

Tenna’s DVIR integrates with its maintenance module to automate corrective action.

- Convert inspection defects into maintenance request tickets

- Track resolution status and history

- Avoid unplanned downtime with proactive service

- Integrate with your ERP to seamlessly convert defects and repairs to Work Orders

“The DVIRs help a lot, especially to know and understand who’s doing them and who’s not, since everyone who drives a company truck is required to. It also helps improve maintenance, because they’re recording whatever’s wrong with the vehicle.”

- D. Guerra Construction

How Tenna’s DVIR Helps Contractors Stay Compliant

Daily inspections are completed before and after shifts or as required

Issues are logged, tracked, and resolved per FMCSA regulations

Records are retained and accessible for required time periods

Be inspection ready—anytime, anywhere.

Improve your fleet health today.

Learn more about how you can reduce risk and simplify DVIR inspections for your field teams.

Frequently Asked Questions

What is a DVIR and why is it important?

A DVIR (Driver Vehicle Inspection Report) is a federally mandated report that commercial motor vehicle (CMV) drivers must complete each workday. It documents the condition of key vehicle components—such as brakes, tires, lights, mirrors, and more—to ensure vehicles are safe to operate.

Tenna’s digital reports automate and simplify this process for construction fleet operators, helping your company:

- Stay compliant with FMCSA 49 CFR §396.11 regulations.

- Reduce paper logs and manual errors.

- Speed up maintenance response times.

- Improve vehicle uptime and safety.

- Eliminate pencil-whipping.

What is included in a DVIR checklist?

A standard fleet checklist includes all the critical components of a commercial motor vehicle that must be inspected to ensure it is safe for operation. These typically include (but are not limited to):

- Brakes

- Lights

- Tires and wheels

- Windshield wipers and washers

- Mirrors and glass

- Steering mechanism

- Horn

- Emergency equipment

- Suspension and coupling devices

- Fuel and fluid levels

- Leaks

- Seat belts and driver controls

Depending on the vehicle type and operation, DVIR checklists may also include custom items like boom arm safety, backup alarms, or jobsite-specific equipment checks—especially for construction fleets.

Digital solutions like Tenna’s allow you to customize these checklists for different vehicle classes and inspection workflows, ensuring compliance and operational safety across your fleet.

How does a digital DVIR system work?

A digital DVIR system replaces traditional paper inspection forms with an electronic workflow that drivers can complete on a smartphone, tablet, or in-vehicle device. Here’s how it works:

- Driver logs into a mobile app at the start and end of a shift.

- Pre-trip and post-trip inspections are completed using a customizable checklist.

- Defects or issues are documented with photos, comments, and electronic signatures.

- Submitted inspection reports sync in real-time with the cloud, instantly alerting fleet or maintenance managers of any flagged issues.

- Maintenance teams review and resolve defects, with status updates and records tracked digitally.

- Reports are stored securely, meeting FMCSA compliance and audit requirements,

- Optional integration with ERP to connect work orders in real time and streamline financial reporting.

Complete systems like Tenna’s go further by integrating DVIR data with fleet maintenance workflows and asset management tools, streamlining communication and reducing vehicle downtime for construction operations.

Read more about Tenna’s holistic approach to driver safety.

Can DVIR reports be customized for construction fleets?

Yes, these inspection reports can and should be customized for construction fleets. Unlike over-the-road trucks, construction vehicles operate in rugged environments and include a wide variety of mixed asset types.

A customizable DVIR and overall inspection system allows you to:

- Tailor inspection checklists for different vehicle classes and specialty equipment.

- Include jobsite-specific safety items (e.g., backup alarms, PTOs, hydraulics).

- Add custom fields like inspection zones, attachments, or operator notes.

- Ensure regulatory and company-specific compliance across mixed fleets.

Let's Discuss Your Needs!

Schedule a Demo