5 Strategies for Construction Site Theft Prevention

- John Jacks

- May 23, 2025

Contractors lose up to 10% of their fleet each year from internal theft and misplacement. External theft pushes this number even higher, with most stolen equipment never recovered.

When equipment theft happens, the problems go beyond just losing the equipment. Your deadlines get pushed back while you find replacements. Your insurance costs rise. Your project manager wastes hours filing police reports. And your clients become frustrated with delays.

We’ve worked with hundreds of contractors who have been burdened by equipment theft and discovered that their approach to equipment tracking had critical gaps that could be addressed with the right systems.

This article will explore the five most practical strategies for construction site theft prevention. For each solution, you’ll discover its key benefits, potential challenges, implementation requirements, real-world effectiveness, and ideal applications for different site sizes and equipment types.

Strategy #1: Equipment Management System

Equipment management software puts all your asset tracking in one place, making visibility simple and centralized. Using geofencing around your project sites in these platforms is a proactive strategy for construction site theft prevention.

Geofence activity triggers an alert to appropriate personnel when assets exit a geofence outside of predefined working hours, making response times to potential theft incidents quicker. These systems use GPS tracking and telematics to monitor where your equipment is and trip details from the trackers can assist law enforcement with tracking down the thief and recovering the asset.

“I just decided to put TENNA Tracking in my new personal work vehicle and it was a good thing I did. When I was at one of our jobs out of state (sleeping over at a local hotel) the truck was stolen at 5:06 am. I know this detail because of how the TENNA system works. I shared this data with the police and they were able to see the criminals in real time driving to another location to steal two more vehicles using my stolen truck. To say the least, TENNA gave me peace of mind that I was going to get my new truck back saving time and money.“

-Kyle C., Kyle Conti Construction

Benefits

- Real-time visibility of all assets across multiple jobsites, showing equipment location down to GPS coordinates

- Immediate notification of unauthorized movement through geofencing, with alerts sent to designated onsite personnel

- Accountability through check-in/check-out procedures, creating digital records of who used what equipment and when

- Prevention and recovery of stolen items, with tracking data that can be shared with law enforcement

Implementation Overview

- Team involvement: Both vendor support teams and in-house staff depending on all solutions being implemented (equipment managers, mechanics, executive sponsors, safety managers, IT, etc.)

- Timeline: 4-16 weeks for full implementation across a mid-sized contractor’s fleet. This varies greatly depending on fleet size and distribution.

- Training: Onboarding and training for end users varies by role and is essential for adoption.

- Process changes: Adjustment to key workflows, such as equipment assignment and transfer procedures, maintenance scheduling and more to digitize processes.

Effectiveness

Equipment management systems provide both prevention and recovery benefits. The presence of tracking devices deters theft, while real-time location data enables quick recovery when theft occurs. Contractors using these systems report significantly more recovery rates for stolen equipment compared to the industry average of 21%.

Beyond construction site theft prevention, equipment management systems aid in improving equipment utilization and maintenance tracking, extending each asset’s useful life in your fleet and maximizing ROI on your equipment investments.

Ideal Applications

- Site sizes: Effective for all site sizes, and particularly valuable for contractors managing multiple sites

- Equipment types: Protects everything from heavy machinery to power tools

- Best for: Contractors with significant equipment investments and multiple ongoing projects

If you’re looking for a construction specific equipment management solution, check out Tenna.

Tenna’s software gives contractors confidence that their equipment is always accounted for. With features like precise geofence boundaries, GPS tracking, and mobile accessibility, contractors can monitor asset entry and exit events and quickly locate equipment.

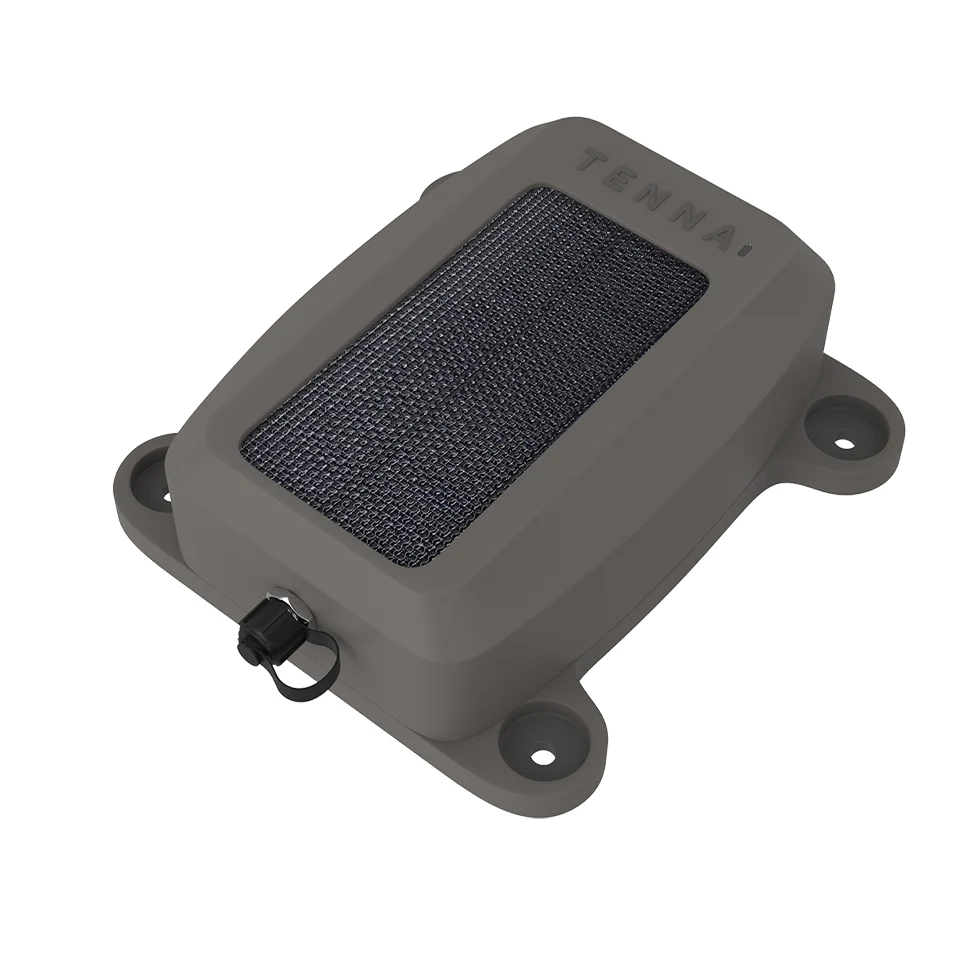

Tenna’s lineup of trackers includes:

TennaCANbus for detailed engine diagnostics and to receive pings 1x/minute when asset is powered on and 1x every 3 hours when asset is powered off

TennaCANbus for detailed engine diagnostics and to receive pings 1x/minute when asset is powered on and 1x every 3 hours when asset is powered off TennaINTEL for GPS tracking and management of high-value, heavy yellow iron assets (reports device position once every 23 hours and pings on motion)

TennaINTEL for GPS tracking and management of high-value, heavy yellow iron assets (reports device position once every 23 hours and pings on motion) TennaFLEET for transmitting telematics data like location, speed, engine hours and other important diagnostic information.

TennaFLEET for transmitting telematics data like location, speed, engine hours and other important diagnostic information.“Tenna helped Ferreira Power West recover a stolen $50,000 truck. Along with the value of the truck, the team saved an unknown amount of money for insurance, claims, damages and medical bills. Not to mention anything else that could have happened after because we recovered it so quickly.”

-Robert C., Asset Manager, Ferreira Power West

Learn how Tenna can protect your construction assets from theft and manage your fleet from one convenient dashboard. Book a demo to see how Tenna can secure your construction equipment.

Strategy #2: Fleet and Equipment Dashcams

While traditional security cameras can help with site security, modern video telematics solutions provide much more targeted protection for your valuable equipment. Solutions like Tenna’s video telematics combine AI-powered dashcams and surveillance capabilities directly on your heavy equipment and fleet vehicles.

Benefits

- Multiple viewing angles covering equipment from various perspectives, providing more comprehensive monitoring than stationary site cameras

- Park mode monitoring continues surveillance even when equipment is powered off

- Dual functionality serving both as theft deterrence and safety compliance tools

- System like Tenna offer integration with GPS tracking to create a powerful combination of location data and visual confirmation

Effectiveness

Video telematics solutions provide the visual evidence missing from GPS tracking alone. When combined with tracking systems, you get both location data and video confirmation of theft events, dramatically increasing recovery rates and providing crucial evidence for law enforcement and insurance claims.

Ideal Applications

- Fleet vehicles: Protects both the vehicle and any equipment being transported

- Heavy equipment: Provides comprehensive visibility for machinery on jobsites

- All jobsite sizes: Scalable solutions that grow with your business

- High-risk areas: Particularly valuable in locations with higher theft rates

Learn more about Tenna’s fleet dash cams.

Other Construction Site Theft Prevention Strategies

While comprehensive equipment management systems and video telematics provide the most effective protection for your assets, contractors often implement additional measures. Here’s a brief overview of other common strategies and why they work best as supplements to the above solutions:

Traditional Security Cameras

Camera systems installed around perimeter and key areas of construction sites record activity and enable remote monitoring. Modern systems include motion detection, night vision, and real-time alerts.

- Visible deterrent to opportunistic thieves

- Video evidence for police reports

- Remote monitoring capabilities

Limitations:

- Cameras are vulnerable to damage or vandalism

- Limited by line of sight and lighting conditions

- Provide evidence after theft but not real-time tracking

- Require power source and internet connectivity

- Most effective for smaller sites (under 5 acres)

Secure Storage and Equipment Lockdown

Physically securing equipment when not in use involves locking compounds, creating secure on-site storage areas, adding equipment lockdown devices, and systematically disabling machinery during off-hours by removing key components.

- Creates multiple physical barriers to theft

- Functions reliably even in remote locations

- Often lower initial cost than technology solutions

Limitations:

- Requires consistent discipline from all team members

- Adds time to start and end of shifts

- May not deter determined thieves with proper tools

- Keys and locks require careful management

Physical Site Security

Establishing strong perimeter protection through temporary fencing, strategic lighting, controlled access points, and alarm systems creates multiple layers of defense against unauthorized entry.

- Creates visible barriers and controls access points

- Improves overall site safety and compliance

- Protects materials and supplies along with equipment

Limitations:

- Requires regular maintenance

- May impede legitimate site access and workflow

- Effectiveness limited without monitoring

- Requires repositioning as project progresses

Security Personnel and Training

People present a strong defense against theft. A combination of dedicated security guards and company-wide awareness training creates a culture where everyone feels responsible for protecting equipment.

- Human observation catches nuanced suspicious activity

- Immediate response to security threats

- Creates a culture of equipment protection

Limitations:

- Represents significant ongoing operational costs

- Effectiveness varies with personnel quality

- Difficult to maintain vigilance across shifts

- Staff turnover requires continuous training efforts

The Most Effective Way to Protect Your Construction Assets

Tenna’s equipment management system delivers what other construction site theft prevention methods can’t: both prevention and recovery of your valuable construction equipment.

While security cameras might leave blind spots and physical security only deters opportunistic theft, Tenna provides real-time GPS tracking and video telematics that watch over your entire fleet. When equipment moves unexpectedly, you’ll know immediately.

Many insurance providers now partner with technology vendors like Tenna to help contractors mitigate theft risks. Ask your insurance provider about potential premium discounts for implementing these solutions – many offer reduced rates for contractors who invest in approved tracking systems and video telematics.

Want to stop worrying about equipment theft and focus on your critical path? See how Tenna can protect your construction assets today.

About John Jacks

John Jacks is an experienced Sales Account Manager and Regional Business Development Manager, currently serving as a Regional Sales Executive at Tenna, where he specializes in SaaS solutions for contractor asset management and GPS tracking. With a strong background in serving industrial and manufacturing clients, John has a proven track record of solving complex problems, reducing operational costs, and improving productivity. His expertise spans sales and rentals of electrical and mechanical equipment, including transformers, compressors, and HVAC systems. John is highly skilled in negotiation, operations management, team building, and sales strategy.