How Construction Equipment Data Fuels Profitability

- William Hipp

- September 11, 2025

The most profitable contractors aren’t just pushing dirt—they’re pushing data. The firms thriving in 2025 are those embracing the digital shift, optimizing operations by leveraging real-time equipment insights to run leaner, smarter jobs. But this shift doesn’t replace gut instinct—it reinforces it. Now, data helps validate those instincts and makes them transferable, which lays the groundwork for stronger teams and smoother succession planning.

From improving equipment utilization to reducing maintenance surprises, data from your machines can unlock dramatic gains in efficiency and profitability.

In this blog, we will explore construction equipment data by looking at its nuances and potential sources. We will also discuss how it affects your profits. Finally, we will explain why choosing the right data platform, like Tenna, can change your fleet from a cost center to a profit engine.

What is Equipment Data in Construction?

Construction equipment data refers to digital information collected from machines, vehicles, and people on a jobsite. This data provides insights into how, when, and where equipment is being used, along with its condition, performance, cost implications and more.

Types of Equipment Data:

- Usage Data: Run time, idle time, travel distance

- Location Data: GPS coordinates, geofencing, theft detection

- Health Data: Engine hours, fault codes, temperature, diagnostics

- Maintenance Data: Service intervals, predictive alerts, inspection history

- Fuel Data: Burn rates, tank levels, refueling events and entries

- Financial Data: Internal billing rates, cost allocation by project or scope of work

.

Data Sources:

- Telematics Devices: Installed directly on machine engine control units to track location, performance and usage, fed to and interpreted in a software platform

- Asset Trackers: Bluetooth trackers for location and transfer activity

- OEM Integrations: Data pulled from original equipment manufacturer systems (e.g., CAT, John Deere, Komatsu, etc.)

- Fleet Management Platforms: Centralized software like Tenna leverages autonomous data sources mentioned above and standardized procedures powered by people to drive clean data. This makes it easier to aggregate and analyze all the data generated across a mixed fleet.

Real-Time vs. Historical Data

A robust fleet management platform should provide both Real-Time and Historical Data.

Real-time data helps field teams make quick decisions. It can reroute assets, catch breakdowns early, respond to fuel needs or help warn users that an asset was stolen or left behind.

Historical data can help tell an objective story and inform long-term strategy; the goal being a happy ending. The long-term strategy includes insights for adjusting the fleet size, improving maintenance schedules, and refining future bids.

The Profitability Equation in Construction

At its core, construction profitability hinges on balancing four major variables:

- Cost: What you spend to get the work done

- Time: How quickly and efficiently you complete it

- Scope/Quality: What’s promised vs. what’s delivered

- Safety: Protecting people, equipment, and reputation

When one of these gets out of balance—say, equipment costs spike due to idle machines or breakdowns—profit margins erode. Construction equipment data helps contractors proactively manage their projects and fleet—resulting in safer execution, on-time delivery, adherence to budget, and completion within the defined scope and quality standards.

6 Ways Equipment Data Directly Impacts Profitability

Here’s how data from your fleet can drive measurable improvements across your operations:

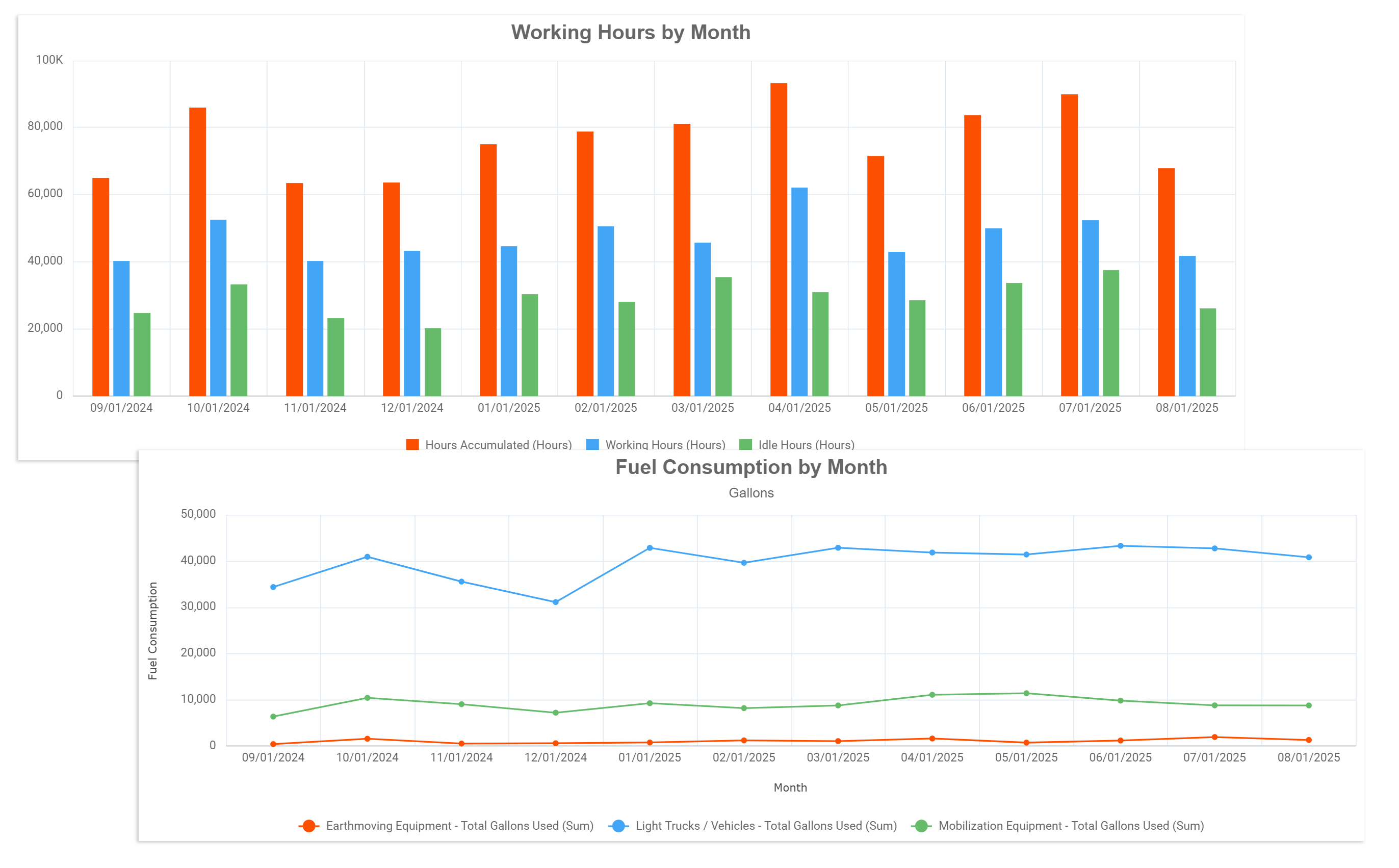

1. Improve Equipment Utilization

Utilization shows whether your assets are being used effectively. Are machines working as planned, or sitting idle? By comparing real run-time data to the assumptions made during bidding, project managers can spot underperforming assets early. This helps prevent missed milestones from turning into lost profits.

Construction equipment data also helps uncover root causes behind low utilization, such as:

- Poor operator training

- Wrong machine for the job

- Redundant assets that can be reassigned or removed

- Weather or site conditions

- Workflow bottlenecks

Armed with this data, teams can adjust quickly to keep productivity high.

2. Reduced Downtime Through Predictive Maintenance

Unplanned breakdowns don’t just stop a machine—they disrupt the entire jobsite. Each incident can cause:

- Delayed timelines

- Emergency repair costs

- Missed deadlines and penalties

Predictive maintenance, powered by telematics and inspection data, helps identify issues before they escalate. By tracking fault codes, service times, and equipment health in real time, contractors can plan maintenance ahead of time. This helps reduce wasteful and unneeded downtime and increase productive uptime.

3. Fuel Planning & Cost Reduction

Fuel is one of the most volatile and expensive operational costs. Construction equipment data provides clarity into:

- Daily burn rates by machine

- Tank capacities and refill schedules

- On-site vs. off-site refueling needs

With this data, site managers can decide whether to use bulk tanks, when to schedule deliveries, and how to avoid delays from empty tanks. Efficient fueling strategies not only save money—they keep crews productive and machines running.

4. Right-Sizing the Fleet for Changing Demands

Your fleet isn’t static and neither are your projects. As job scopes shift, timelines accelerate, or work types evolve, your fleet must adapt in step. Right-sizing and modernizing is about aligning your equipment, trucks, and vehicles with actual project needs—not just based on what you own but based on what the future demands.

Key considerations include:

- Project Profile Shifts – New phases or scopes may require different asset types, counts, or capabilities.

- Aging Equipment – Without a proactive replacement strategy, outdated, less efficient machines can lead to downtime, safety issues, or runaway costs.

- Shop–Field Misalignment – Poor communication between the field and equipment teams can leave crews unsupported or oversupplied with the wrong assets.

Tenna helps equipment managers respond to these challenges with tools like Resource Management, Schedule View, and Age Forecasting, providing the data and visibility needed to plan ahead, adapt confidently, and optimize fleet investments.

5. Enhancing Job Costing and Billing Accuracy

From a project cost perspective, equipment doesn’t follow the same rules as labor and materials. Equipment costs don’t appear steadily, but rather, they come in bursts and don’t always align neatly with when or where the equipment was used. This makes it difficult to pinpoint the actual cost of using a machine for a short period on a specific job.

Using equipment rates and telematics data, contractors can:

- Assign a fair, consistent cost for the portion of equipment time used by the project.

- Generate equipment department revenue from internal or external charges.

Charging jobsites a usage-based rate helps offset the lifecycle cost of owning and maintaining the fleet. This system brings structure to the unpredictable nature of equipment costs, thus allowing teams to make better decisions with more reliable data. The byproduct of an internal or external equipment charge mechanism is a pseudo budget to help justify repair and rebuild decisions.

6. Safety and Compliance Improvements

While safety efforts often focus on personnel, equipment can be a blind spot. A daily walk around procedure is critical to ensure jobsite safety when machines are involved. However, it is susceptible to four failure points:

- Has there been adequate training to understand the inspection points?

- Are inspections completed when prescribed?

- Does the supervisor hold operators accountable?

- Do the results get communicated back?

Construction equipment data and a solution like Tenna can bridge that gap by:

- Inspection forms with custom descriptions to provide context of pass/fail criteria

- Automating daily inspections and checklists

- Tracking compliance with safety protocols

- Communicating defects or hazards to technicians that can fix the problem

Early reporting of minor issues can prevent catastrophic failures later—protecting workers, schedules, and your bottom line.

Choosing the Right Equipment Data Platform

Not all platforms are created equal. When selecting a construction equipment data solution, look for:

- Integrations with Mixed Fleet and OEMs – Your data platform should unify information from all machines in your fleet – regardless of brand, age, or type. Native OEM integrations and API flexibility keep every asset included.

- Real-Time Tracking – Live updates from the field help foremen and dispatchers make quick, informed decisions. They can reroute equipment, solve problems, and reduce idle time.

- Reporting and Analytics Dashboards – Dashboards should provide customizable, visual insights into utilization, maintenance, cost allocation, and more. The ability to export or integrate with other systems (like ERPs or accounting software) is a plus.

While there are general fleet tracking platforms available, solutions made for the construction industry—like Tenna—provide more value. Construction sites have unique needs, from rugged environments to mixed fleet complexities. A platform that is designed for these challenges will provide more accurate data and more relevant insights.

Conclusion: Turning Data into Dollars

The message is clear: construction equipment data isn’t a luxury—it’s a necessity in the modernizing industry. Contractors who harness the power of their machines’ data are seeing:

- Higher utilization rates

- Fewer breakdowns and delays

- Lower fuel and maintenance costs

- More accurate billing and job costing

- Safer, more compliant jobsites

Profitability in construction hinges on informed decisions—and those decisions rely on data. With the right tools and the right strategy, your equipment can become one of your most powerful assets for growth.

Ready to unlock the full value of your fleet? Learn how Tenna’s construction-specific platform can help you collect, analyze, and act on your construction equipment data to deliver better outcomes across every jobsite.

About William Hipp

As a Product Analyst for Tenna, Will supports the product roadmap and manages the lifecycle from idea conception to production. With a decade of experience as a Certified Public Accountant in Big Four accounting, multinational manufacturing, and construction equipment management, Will has developed a strong foundation in finance and analytics. During his four years in construction equipment management, he utilized his analytical skills to build robust models that leverage leading and lagging indicators to inform strategic decisions. These decisions include identifying the optimum ownership period, setting accurate equipment rates, and making data-driven choices regarding repair, replacement, and disposal strategies. His commitment to excellence and efficiency ensures that Tenna is grounded in solid analytical practices aimed at providing strategic insights.