Equipment Maintenance Software Built

for Construction

Manage, Track,

and Optimize the

Equipment Health of Your Entire Fleet

Designed specifically for the construction industry, Tenna unites your fleet maintenance operations with your equipment data, mechanic labor, cost codes, and parts inventory on a single, integrated platform.

Maintenance Solutions Tailored To Contractors

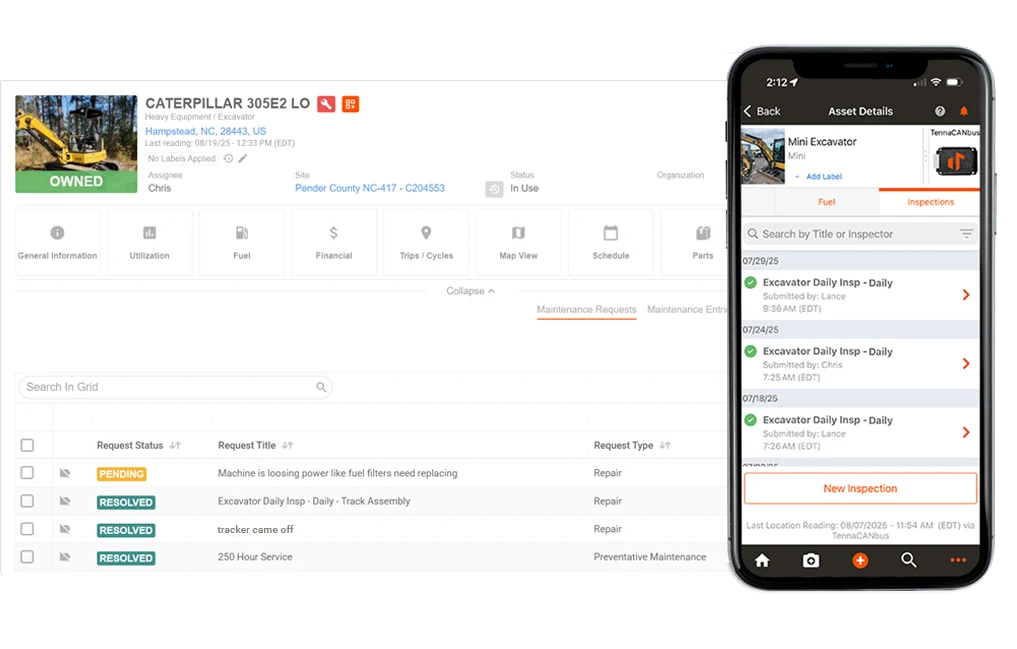

Tenna brings all your maintenance operations into a single platform. Whether you’re servicing yellow iron, pickup trucks, attachments and everything in between, we help you track equipment fleet maintenance across the full asset lifecycle.

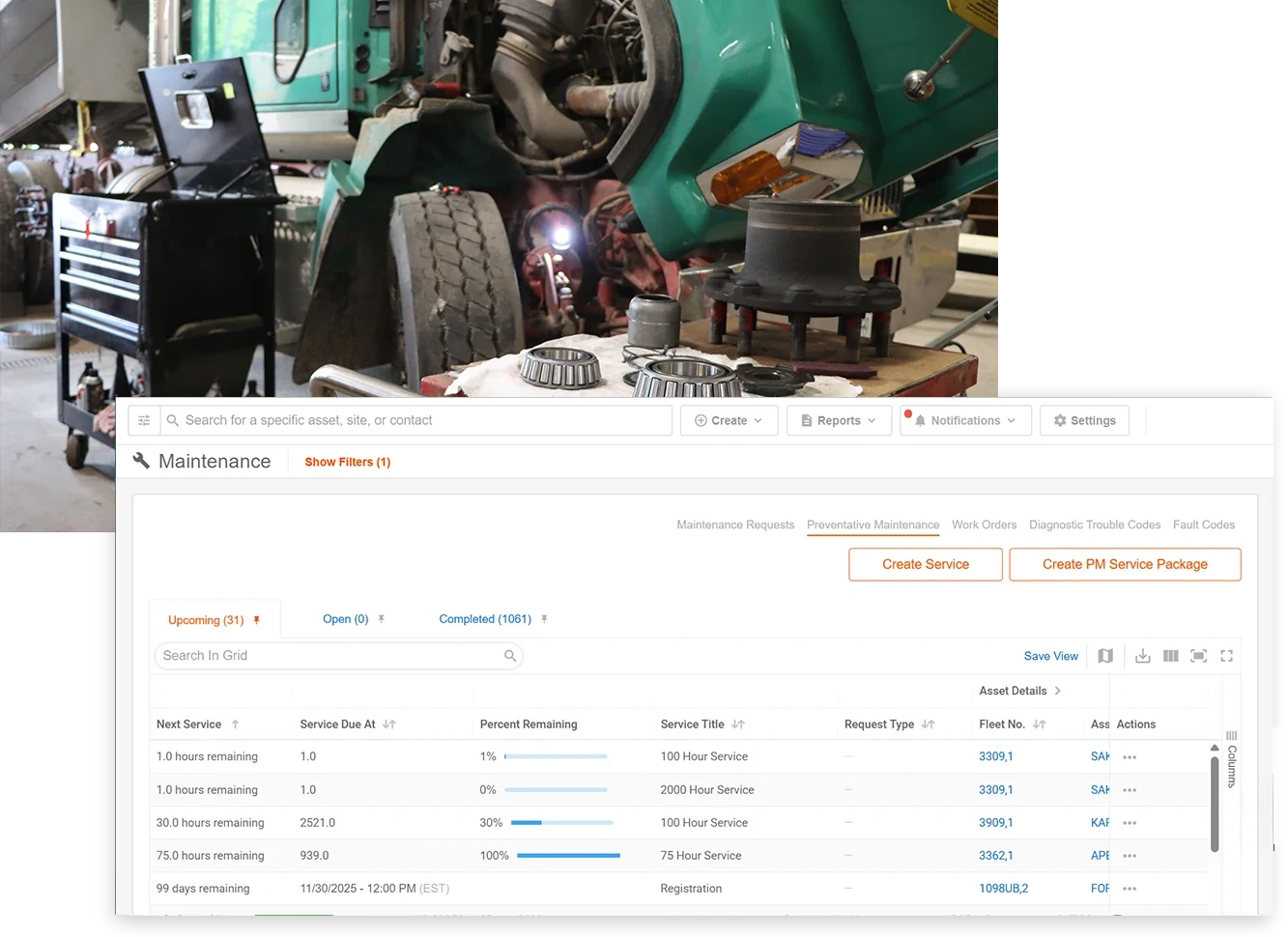

Stay ahead of breakdowns. Configure and automate routine service intervals based on usage (hours/mileage) or time and get alerts when preventive maintenance is due.

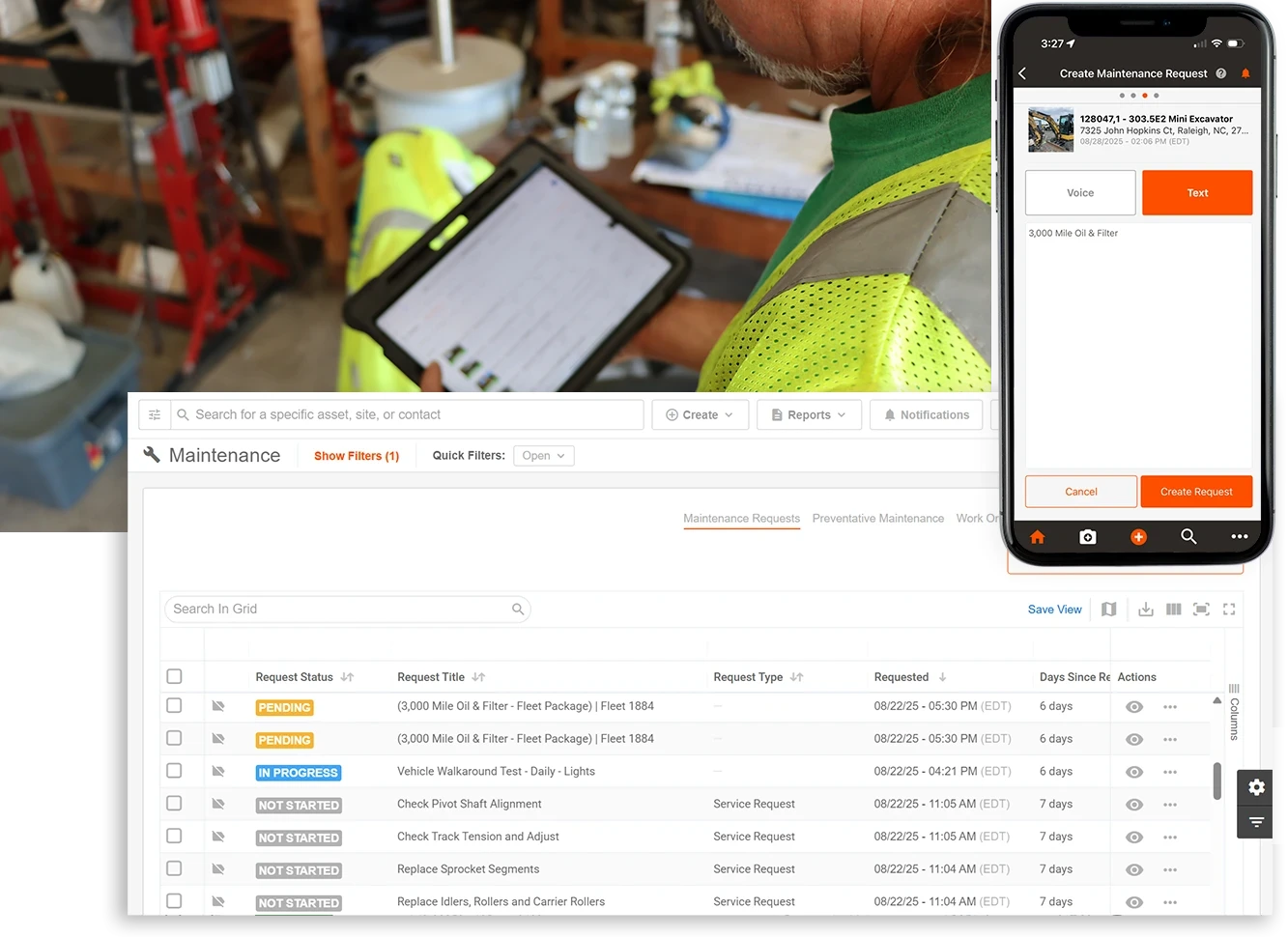

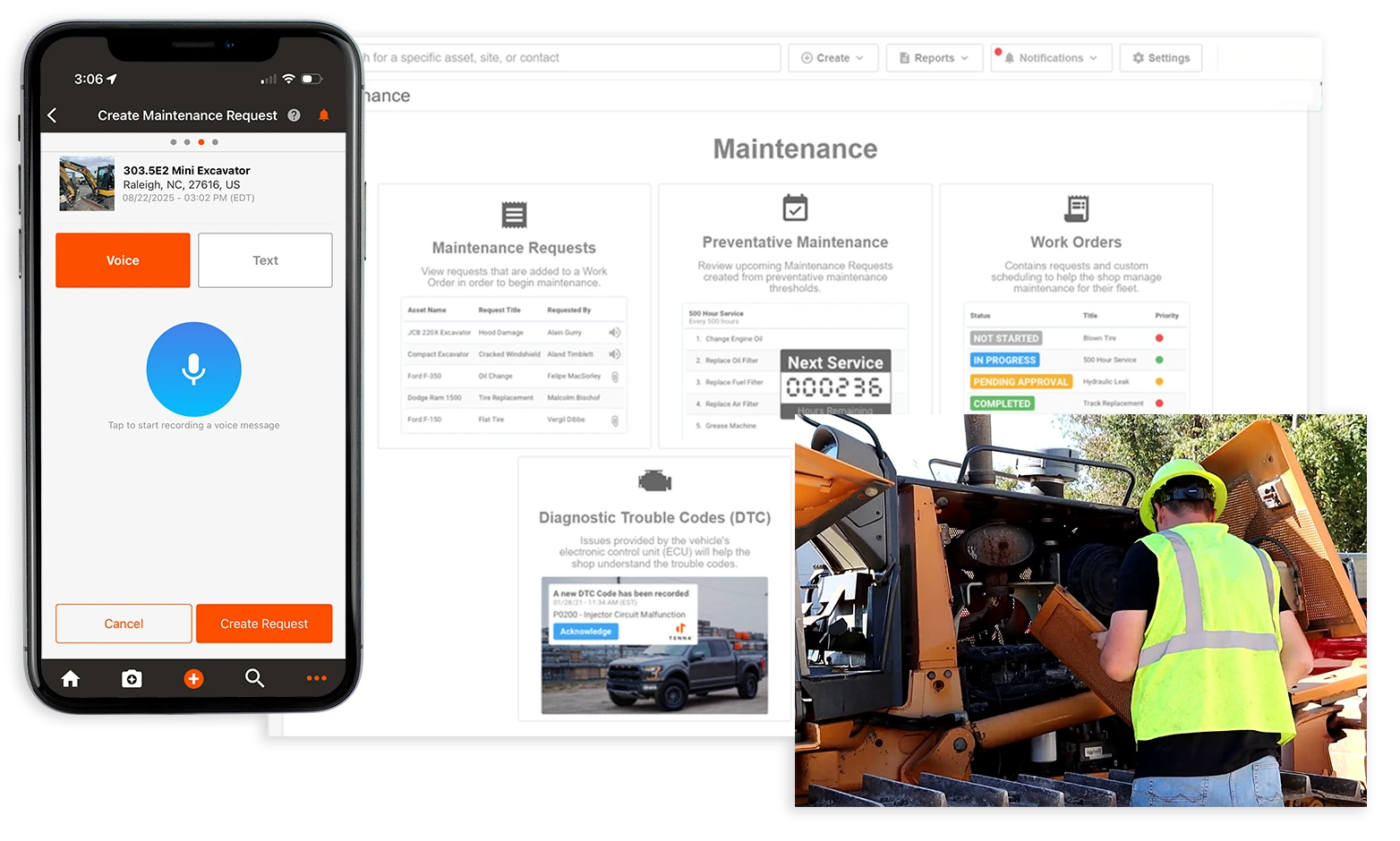

Submit maintenance requests directly from the field easily with Tenna’s equipment maintenance software through voice memos, text notes and on-the-go submission capabilities using the Tenna app for speed and efficiency.

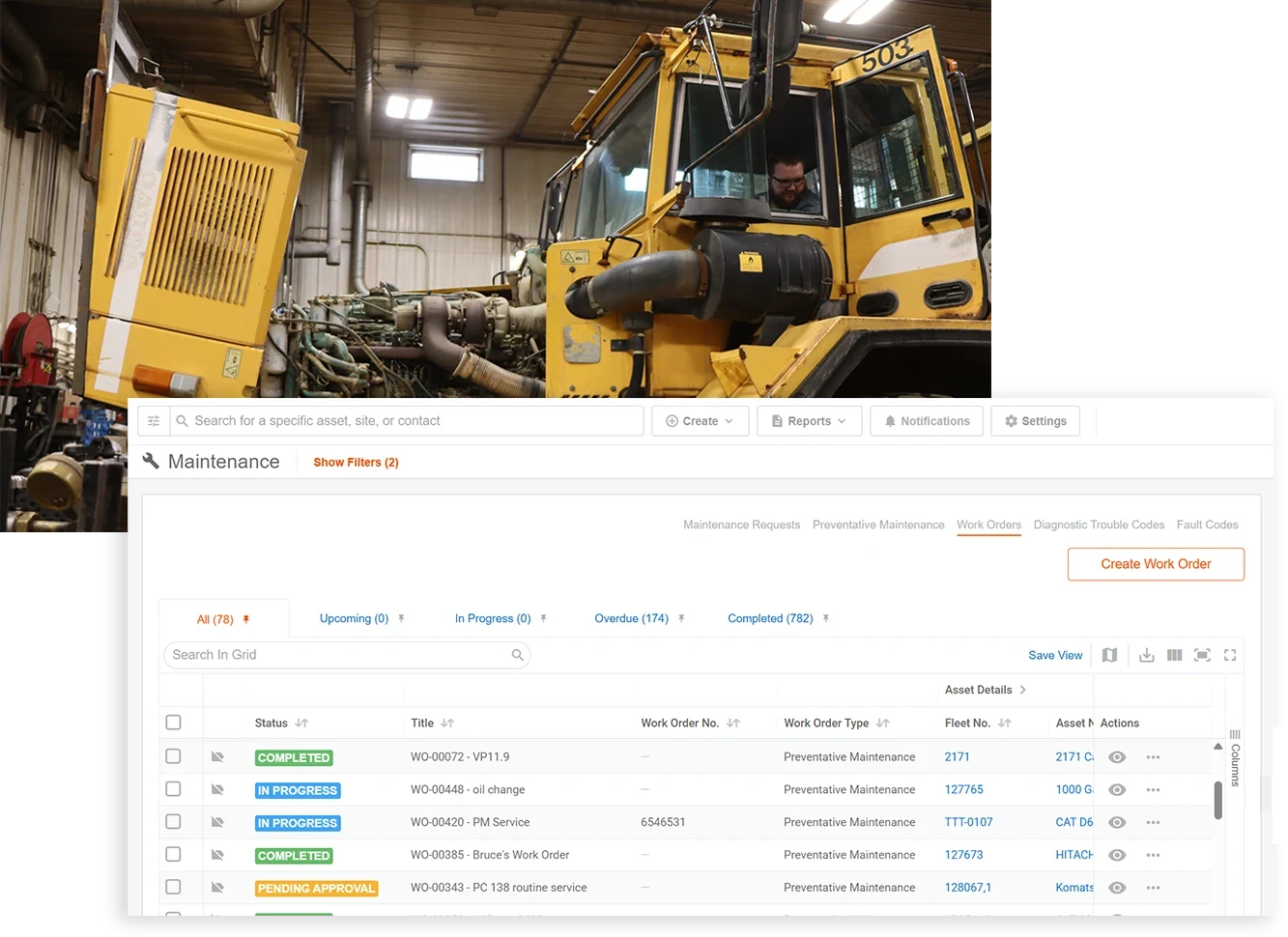

Create and track maintenance work orders in real time. Collect all maintenance requests and services for an asset and track them to completion, with photos, details, parts and labor associated with each event for efficient billing and cost control.

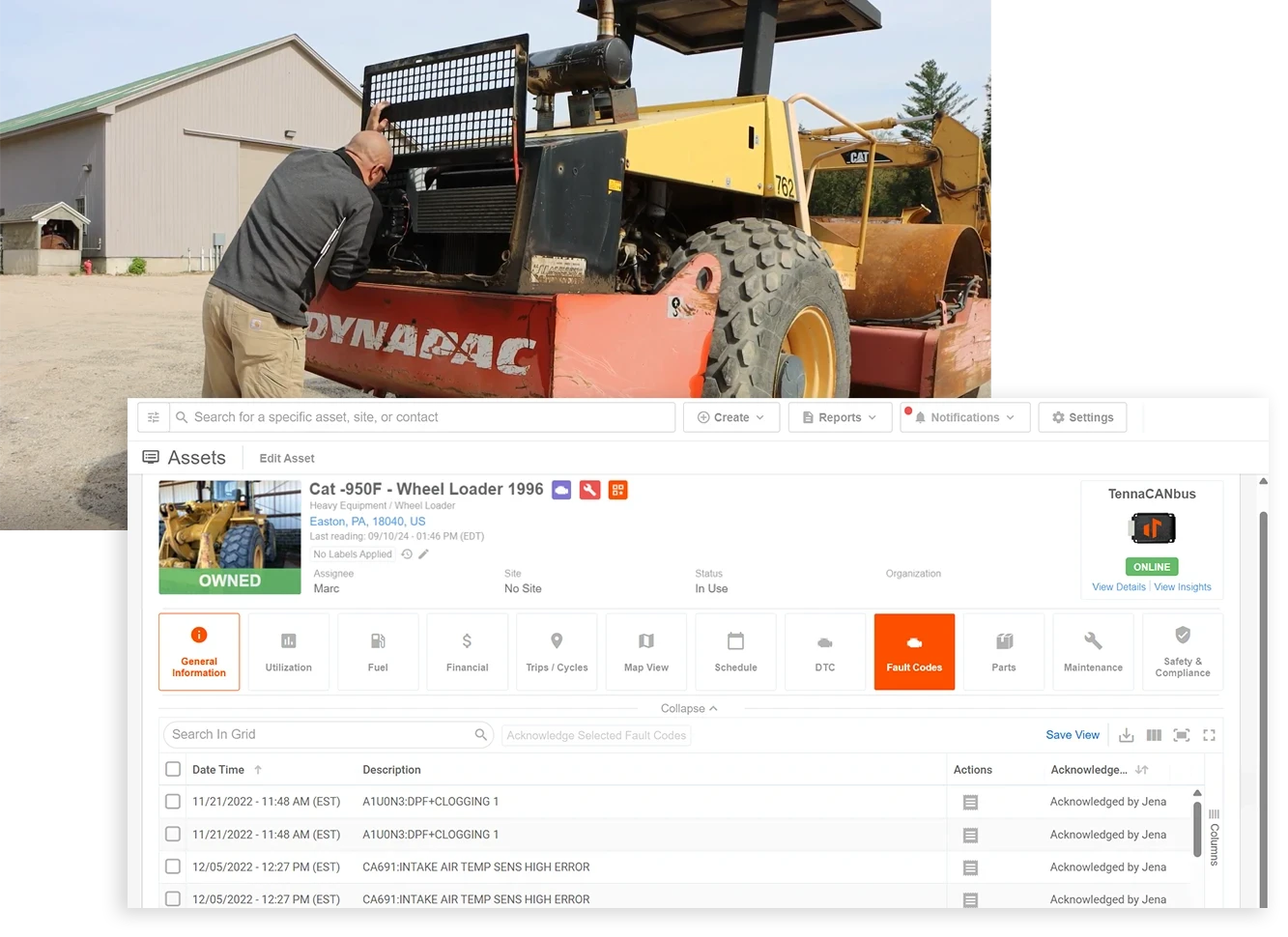

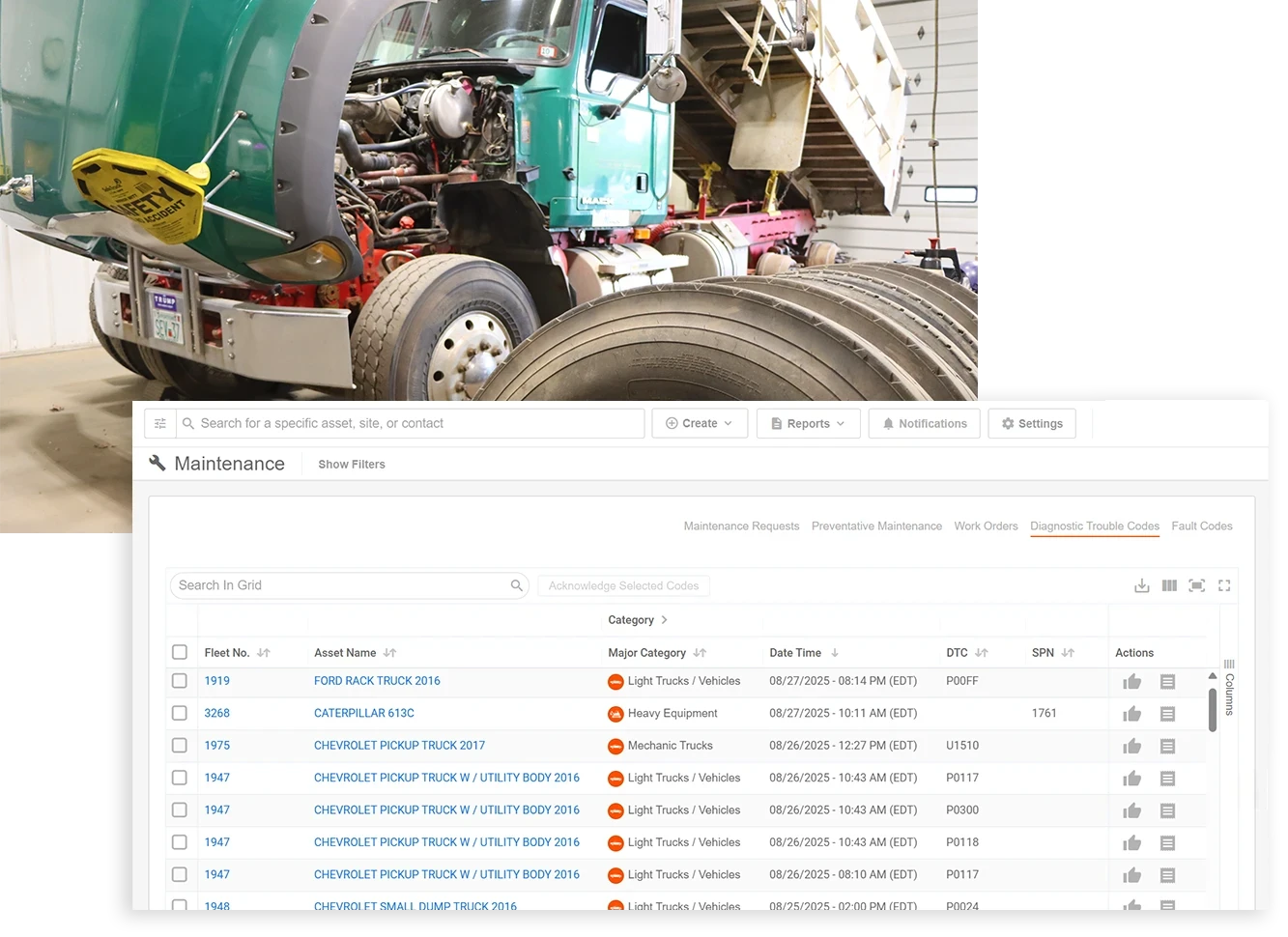

Be alerted about issues with your equipment transmitted by Tenna’s equipment GPS tracking devices or via your OEM/AEMP integrations with fault codes. Your shop can take or request action directly from within the Tenna platform.

Understand diagnostic trouble codes provided by your vehicles’ electronic control unit (ECU) via Tenna’s fleet tracking devices. Get to the root of your mechanical issues before they affect operations.

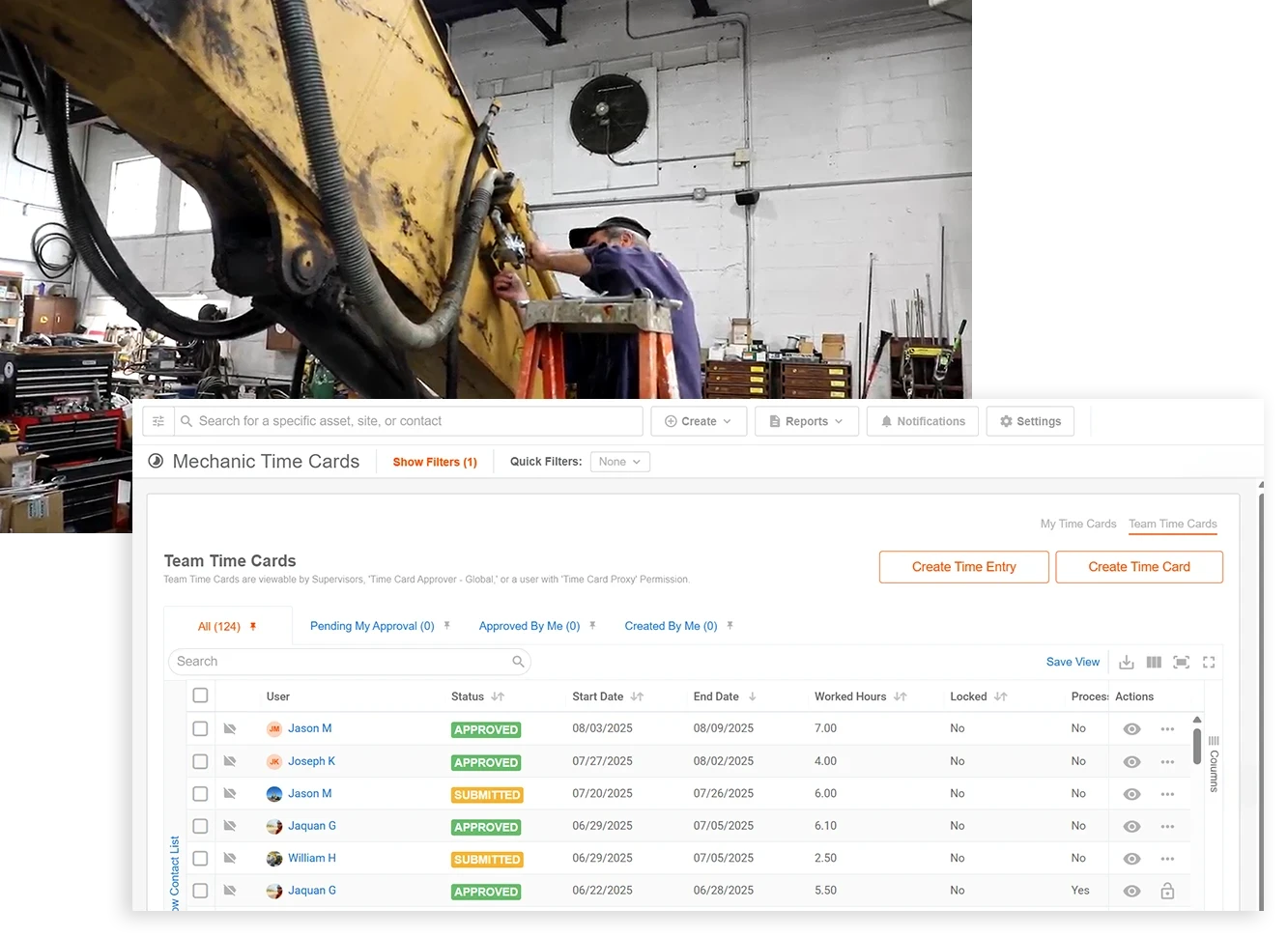

Log wrench time, not just work time. Technicians can log their work hours, track labor by specific equipment, job or cost code with mechanic time cards. Capture mechanic time worked against your work orders and maintenance requests.

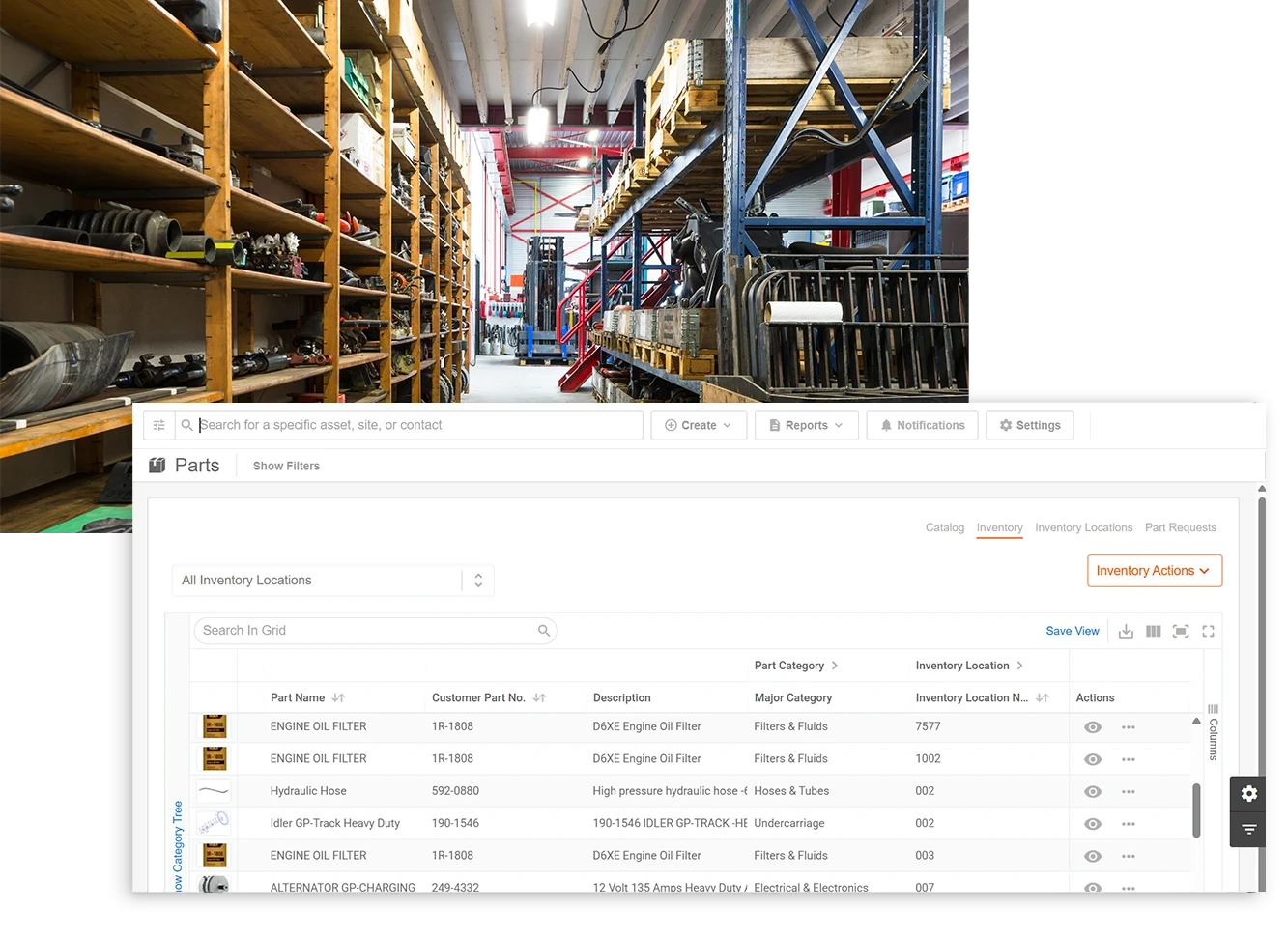

Track every part, kit, and supply. Easily request parts from the field, get real-time visibility into parts inventory across locations, configure restocking alerts, and link usage to service tasks for quality and cost control.

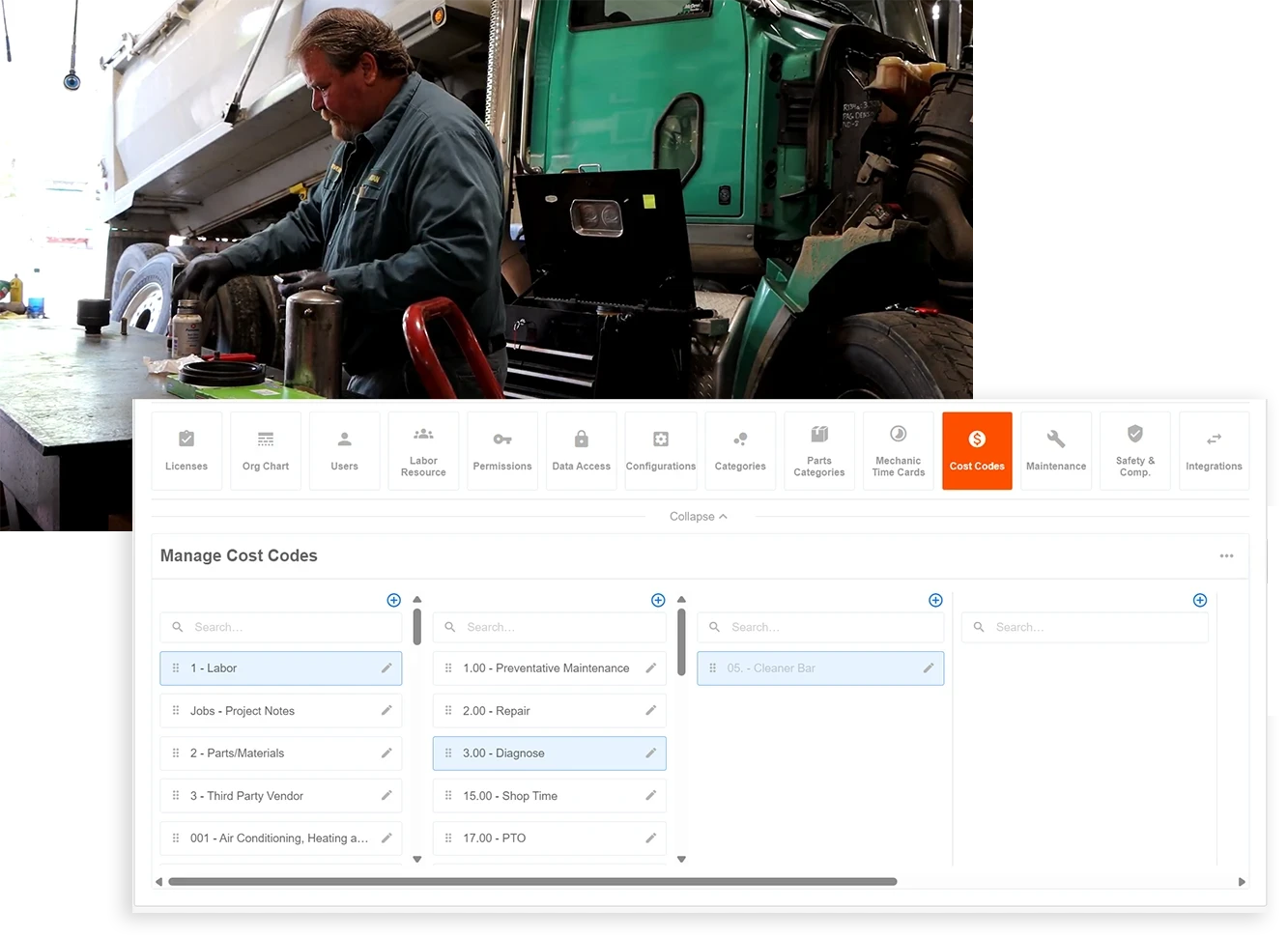

Account for labor and materials to the right job. Assign cost codes to every part and maintenance task and get accurate job costing data across your operations.

Why Contractors Choose Tenna for Maintenance

Tenna’s construction equipment maintenance software is an all-inclusive CMMS for contractors, built into Tenna’s equipment management platform.

Connect maintenance with tracking, utilization, inspections, and more.

Automate preventative maintenance and reduce

costly breakdowns.

Centralize mechanic time and cost codes against

fleet assets.

Keep accurate track of parts inventory across locations.

Maintain fleet health and operational safety standards.

Leverage a single system for visibility, accountability,

and ROI.

The Power of Unified Maintenance Data

Unlike siloed maintenance systems, Tenna’s platform brings every part of your equipment management operation together. With Tenna, you don’t need five different systems to run your shop. You just need one built for construction.

Centralized Equipment Maintenance Records

- Full visibility into service history by asset for greater resale value

- A clean audit trail for fleet compliance

- Clear insights into maintenance trends

- Better coordination between field, shop, and office

Designed for Construction Workflows

- Built for heavy equipment, trucks, vehicles, attachments and tools

- Accessible via mobile for field and shop users

- Connected to utilization, DVIRs, inspections, and GPS data

- Easy to use in fast-paced environments

Ready to Run a More Reliable Fleet?

Take control of your equipment maintenance operations with a system designed for construction. Let Tenna help you boost uptime, reduce costs, and stay on top of your entire fleet.

Ready to See More?

Schedule a Demo