Tenna Customer Story

One Solution for Heavy Civil Equipment Management

From excavators to attachments and pumps, RP Constructors needed one connected system to manage its growing fleet — and the insight to make faster, smarter decisions across every division.

At a Glance Results

Improved visibility

across all job sites

Faster dispatch

and real-time decision-making

Accurate billing

with verified utilization data

Reduced insurance

losses through video proof

Safer driving

with Driver Scorecards

Lower fuel costs

by identifying idle time

Seamless

Procore and Foundation integration

“We believe we’re on the leading edge of technology in our world, and we’re picking partners that are also pushing for improvements.”

Travis Thom,

Vice President

The Challenge: Disconnected Systems and Limited Visibility

Managing a mixed fleet across multiple job sites was slowing RP Constructors down. With 17 excavators, six loaders, and countless attachments and pumps, visibility was limited — and communication gaps led to wasted time, missed billing, and delayed maintenance.

Without GPS tracking built for construction, field teams relied on calls and guesswork to locate assets. Leadership lacked confidence in utilization data, and billing required manual cross-checks between systems.

The team’s goal was clear: a connected platform that could show where everything is, how it’s being used, and how to bill accurately — in real time.

The Solution: A Connected Platform Built for Heavy Civil

When RP discovered Tenna’s purpose-built platform for heavy civil contractors, they immediately recognized its value.

“Traditional GPS systems for on-road fleets isn’t the same for heavy civil constructors,”

— Travis Thom, Vice President

Now, Tenna connects every team, site, and system:

- Field Foremen track specific units and attachments via mobile app.

- Maintenance Teams rely on automatic work orders and service scheduling.

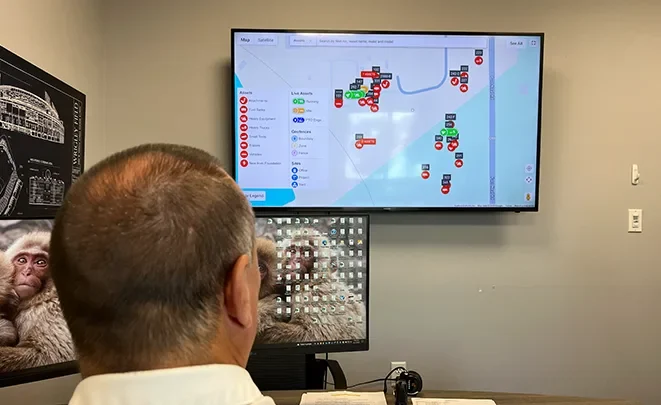

- Leadership monitors live maps, utilization reports, and cost analytics.

“My main TV has Tenna up — typically on the live map. When we want to know where someone is or a piece of equipment is, or I get that call, I pull it up and know exactly where it’s at.”

— Phil Sorenson, Director of Logistics, Overhead & Maintenance

Through integrations with Procore and Foundation, RP’s field data now flows directly into project management and accounting, eliminating duplicate entry and making billing cycles faster and more transparent.

“Tenna has helped us bridge the gap with Procore and Foundation. It’s helped us become more efficient with billings and basically everything that has to do some way, shape or form with running RP and CEC.”

— Phil Sorenson, Director of Logistics, Operations & Maintenance

The Results: Efficiency, Accountability, and Smarter Decisions

Real-Time Asset Visibility and Faster Operations

Live GPS mapping means RP can locate, move, and dispatch equipment instantly.

“We had parts we needed quickly and we were able to use the GPS mapping and figure out who was close to the facility. They swung in and saved us time and effort”

— Travis Thom, Vice President

“Knowing where we leave a bucket is very important to us. Tenna’s attachment piece is second to none.”

— Travis Thom, Vice President

Accurate Billing and Verified Equipment Utilization

With Tenna’s utilization data, RP confidently bills clients for every hour of machine use — backed by proof.

“On design-build jobs, we can pull a report on the hours of each unit being used within the site. We’re able to pull every piece of equipment and show its hours for each month and bill accurately,”

— Phil Sorenson, Director of Logistics, Overhead & Maintenance

“We aren’t just John Wayne-ing some numbers. We’re able to establish good relations with clients and show that we’re organized and have the ability to track our equipment hours.”

— Travis Thom, Vice President

Enhanced Safety and Driver Accountability

AI Dash Cams became essential to protecting both people and assets. “The original push for cameras came from our insurance company, our captive insurance,” said Thom.

“The original push for cameras came from our insurance company, our captive insurance,”

— Travis Thom, Vice President

“The video takes the argument out of the equation. Now that we have them, we feel the cameras are more of an asset towards us, and I think our employees would agree that they’re an asset for them for protection.”

— Travis Thom, Vice President

“Most drivers have been more conscious of what they’re doing behind the wheel. We have seen improved scorecards. It’s just part of their daily routine now.”

— Phil Sorenson, Director of Logistics, Overhead and Maintenance

Streamlined Fleet Compliance and Fuel Efficiency

Paper inspections are gone. Digital DVIRs keep everyone compliant and informed.

“Drivers love that they don’t have to keep these books and turn them in every morning or week,”

— Phil Sorenson, Director of Logistics, Overhead and Maintenance

“The most valuable things for me are the Tenna reports and being able to pull usable hours or look at why are we using more fuel in these certain months versus others.,”

— Phil Sorenson, Director of Logistics, Overhead and Maintenance

Revenue

$1.5–$2.5M

annual profit

Fuel Savings

$9,000 a month

in savings

Theft Recovery

$120k recovered

within an hour

Safety

D/F grades

near zero

Compliance

100% preventive

maintenance on time

A Partnership That Drives Progress

Beyond the technology, RP Constructors values Tenna’s partnership and support.

“They’re constantly improving,” said Sorenson. “I can schedule an appointment and have them come up physically versus just working through emails and phone calls and help chats. But those are all right there and available and that’s been really helpful for me.”

— Mark Marcelli, Logistics Manager

As RP continues to grow, the company uses Tenna to forecast workloads, rentals, and future equipment needs.

“It helps us see the big picture — where each piece of equipment is and when we’ll need it next or when to rent.”

— Travis Thom, Vice President

Explore the Heavy Civil Equipment Management Tools That Power RP’s Success

See How Other Contractors Are Building Efficiency and Safety

with Tenna

Get a Personalized Demo

Book a Demo