Smarter Construction Inventory Management for Mixed Fleets

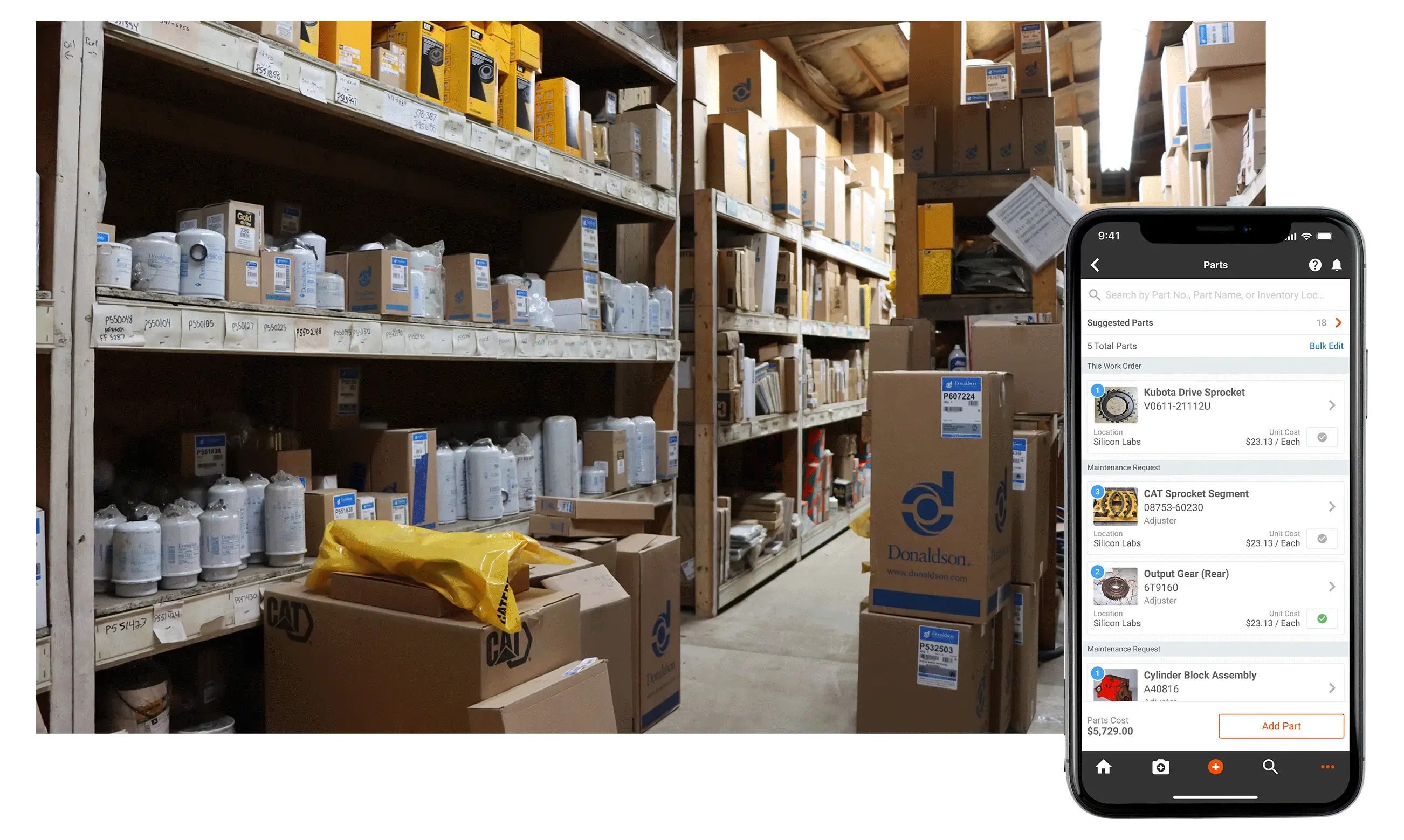

Keep your fleet running and your projects on track with complete visibility and control over your parts inventory

Manage Your Parts Inventory

Managing parts inventory is a critical but often overlooked component of construction operations. Between juggling jobsite needs, maintenance schedules, and procurement, construction businesses face significant challenges tracking the parts they have, the parts they need, and where everything is located.

With Tenna’s construction inventory management solution, you gain real-time visibility and control over your parts inventory—ensuring that the right components are available at the right time in the right place to keep your equipment and projects running smoothly.

Why Construction Businesses Need a Parts

Inventory Management Solution

Construction companies manage complex scattered fleets and multiple job sites, making parts inventory difficult to control without a centralized system. Without proper inventory management, teams often face:

Unplanned Downtime

Delays in equipment repairs

because of missing parts

Inaccurate Stock Levels

Overstocking or understocking common parts

Wasted Spend

Buying parts that are already in stock, just in the

wrong place

Inefficient Requests Systems

Inability to reference true parts catalog or exact

part needed

Manual Tracking Errors

Spreadsheet-based or paper systems lead to inaccuracies and inefficiencies

An effective construction inventory management system empowers you to address these issues by creating transparency, accountability, and real-time inventory data access across your operations.

Benefits of Managing Parts Inventory with Tenna

Reduce Equipment Downtime

Ensure that your maintenance teams have the parts they need, when and where they need them. Tenna enables teams to schedule repairs more efficiently and avoid delays caused by missing or mislocated parts.

Optimize Stock Levels

Get insights into usage trends by site or individual machines, part quantities, and reorder thresholds to prevent overstocking or running out of parts. Set minimum quantities and receive alerts when parts fall below those levels.

Eliminate Redundant Purchases

Make sure your purchasing and maintenance teams can see what is already in inventory. This will help avoid accumulating duplicate parts across all your yards and shops.

Improve Operational Efficiency

By using a central digital platform instead of old manual methods, you save time on admin tasks. This also lowers human error and speeds up maintenance workflows.

Centralize Data for Usage Insights

When your parts inventory data is in your equipment management platform, you can track parts usage trends by asset type, class, or jobsite.

Track Parts Costs

Link parts' costs to actual work against individual assets and jobsites for clarity into budgeting, cost reporting, and job performance tracking. Track parts costs per service, maintenance spending per asset, and better forecast projects.

Why Integrated Construction Inventory Management

Is a Game-Changer

Most construction companies use separate systems for inventory, maintenance, and fleet management.

This disjointed approach creates gaps and inefficiencies.

Tenna brings all this data together.

One System, One Source of Truth

With Tenna, parts inventory management is not a separate tool—neither is your CMMS. Maintenance is an integrated feature of your construction equipment management system. This connection ties parts data to specific equipment, maintenance schedules, work orders, and job sites.

Smarter Maintenance Planning

When your mechanics can see what parts are in stock as they receive and plan work orders, they make smarter decisions and avoid delays. Procurement teams can see what parts are moving fast and reorder intelligently.

Streamlined Communication

Reduce back-and-forth between mechanics, operations, and procurement teams. Everyone has access to the same live data about inventory, part usage, and locations.

How Tenna’s Parts Inventory Management Works

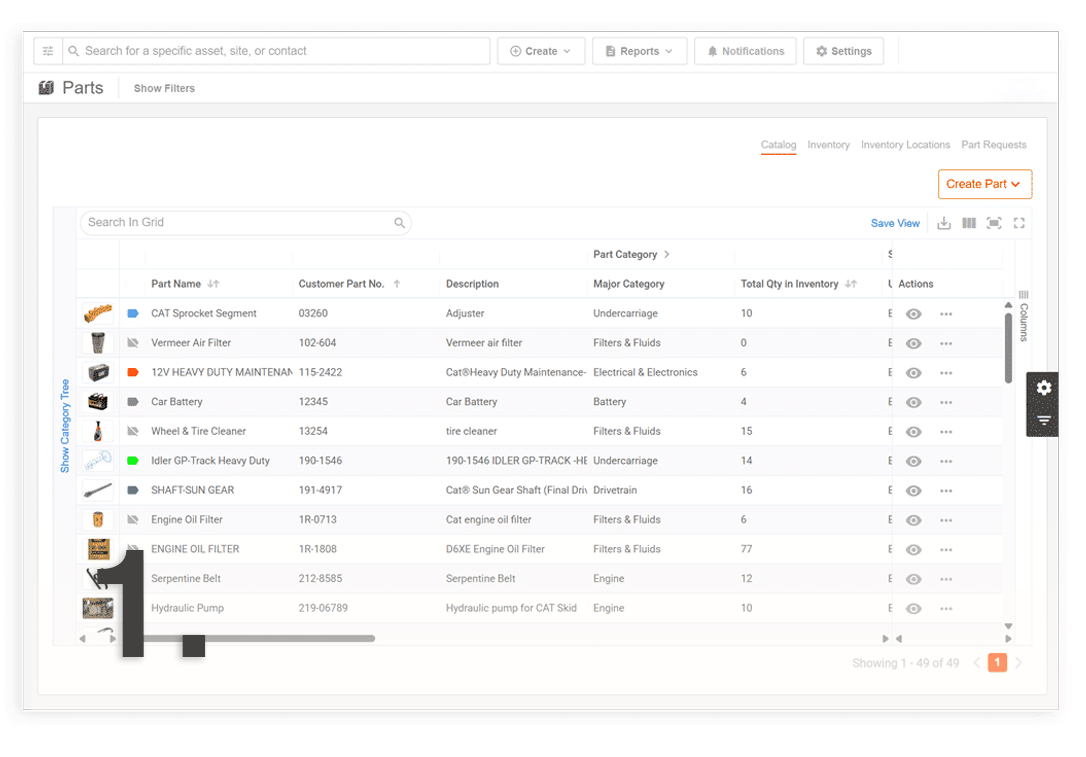

1. Build Your Own Parts Catalog

Build your custom parts catalog filled with inventory parts that apply to all the machines in your fleet as well as the tools required to service them. Assign inventory numbers to each category of item for easy classification and identification.

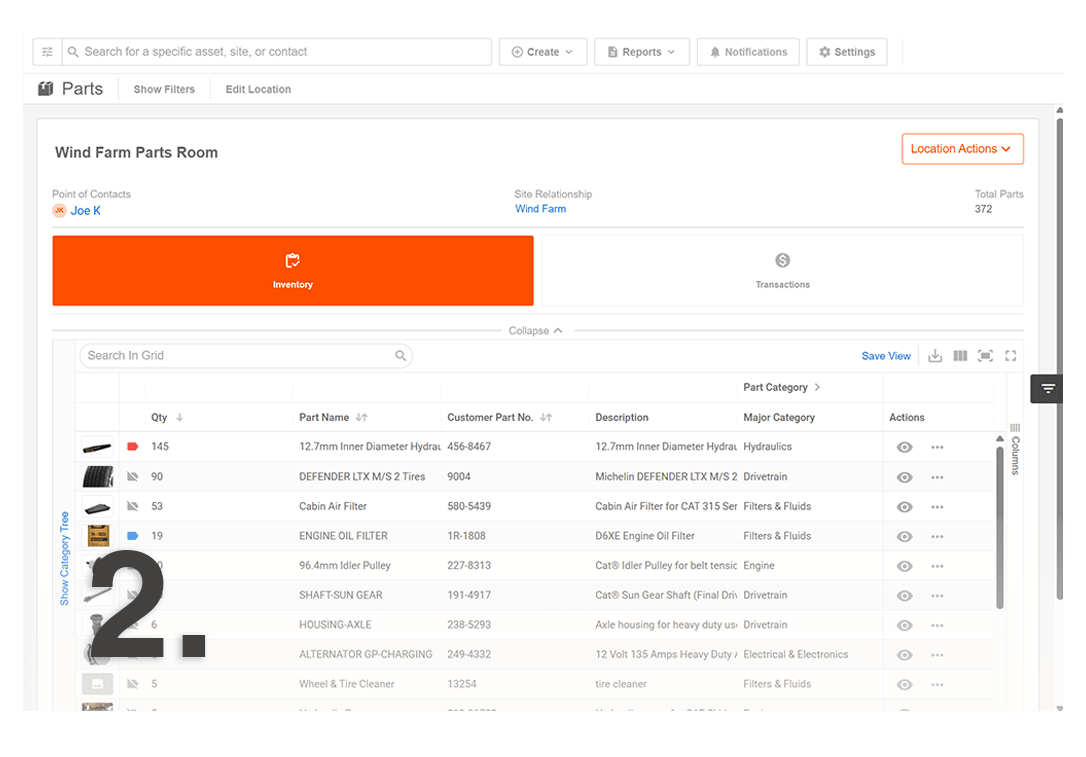

2. Real-Time Inventory Visibility

Track your entire parts inventory across shops, yards, and warehouses with real-time visibility. Each item is associated with data including part number, description, quantity, location,

and status.

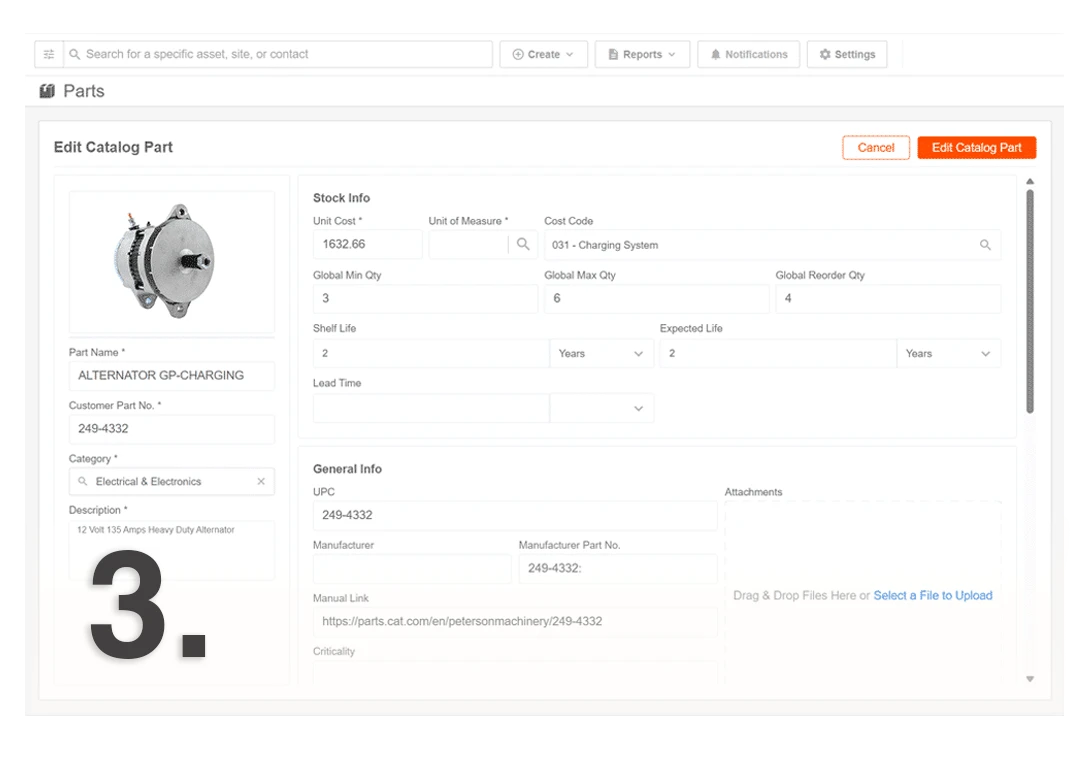

3. Custom Part Profiles

Create detailed records for each part including manufacturer info, compatible equipment, pricing, and reorder thresholds.

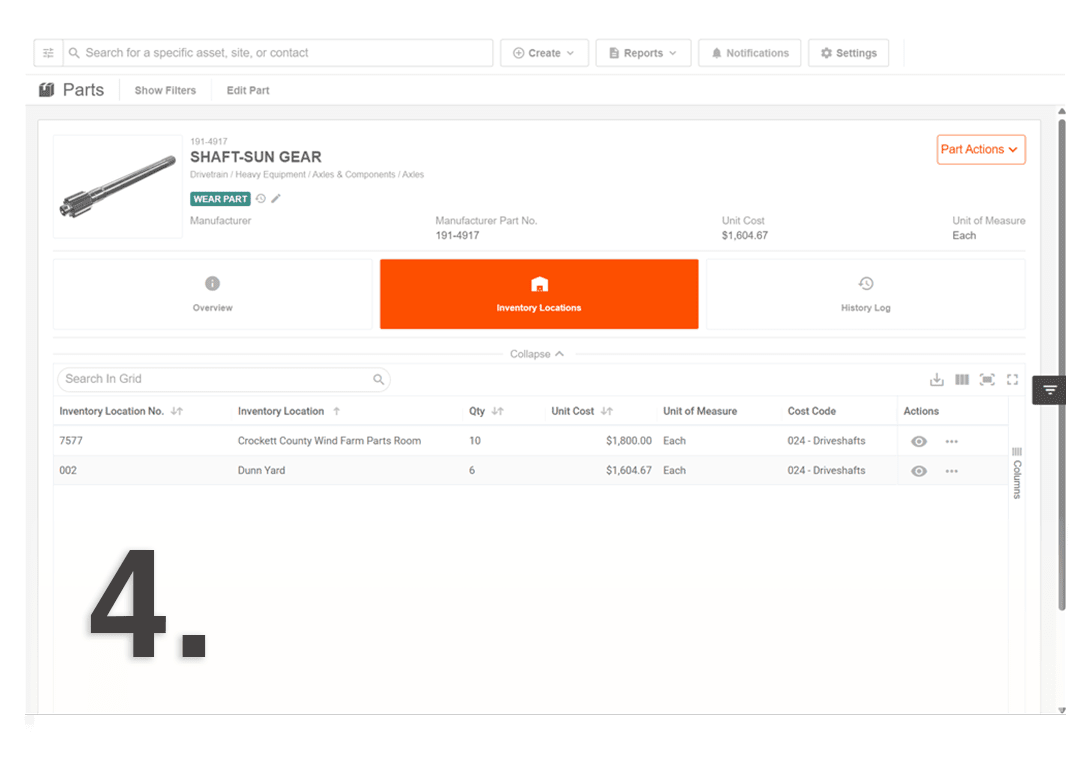

4. Location-Based Tracking

Know exactly where your parts are—down to the building and shelf—so that your crews don’t waste time searching or guessing.

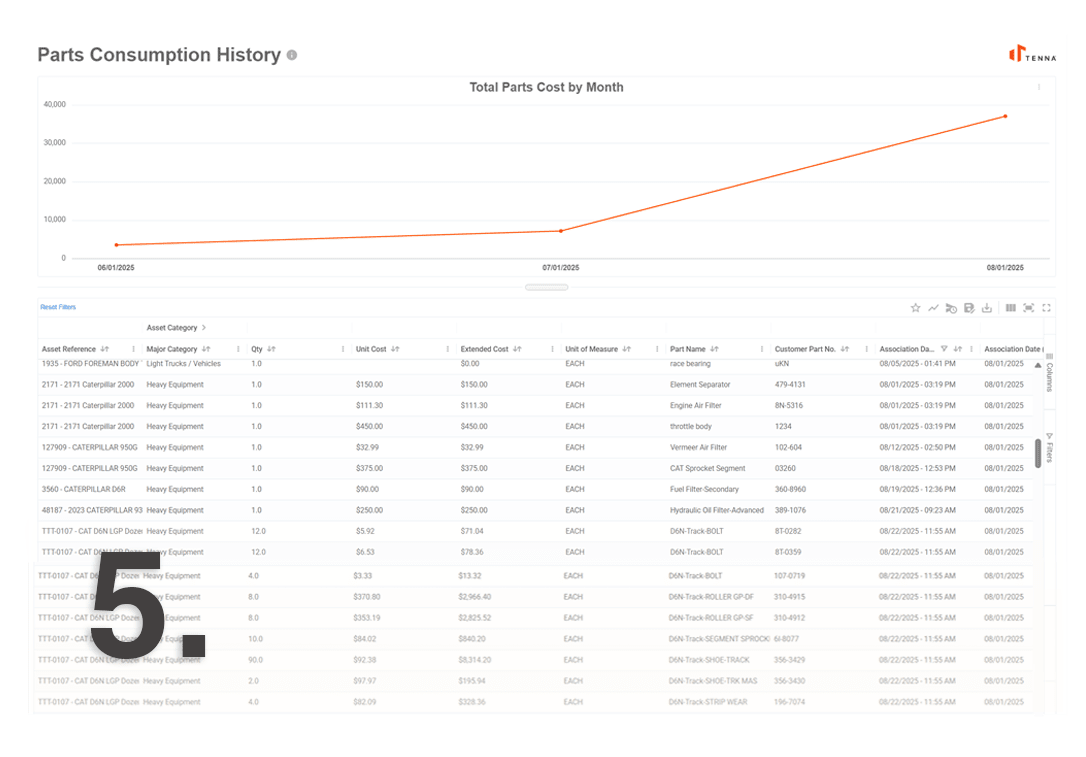

5. Parts Usage and History Logs

Track how often parts are used, when they were last installed, and on what machines. Analyze part lifecycles and make data-driven decisions about quality and purchasing.

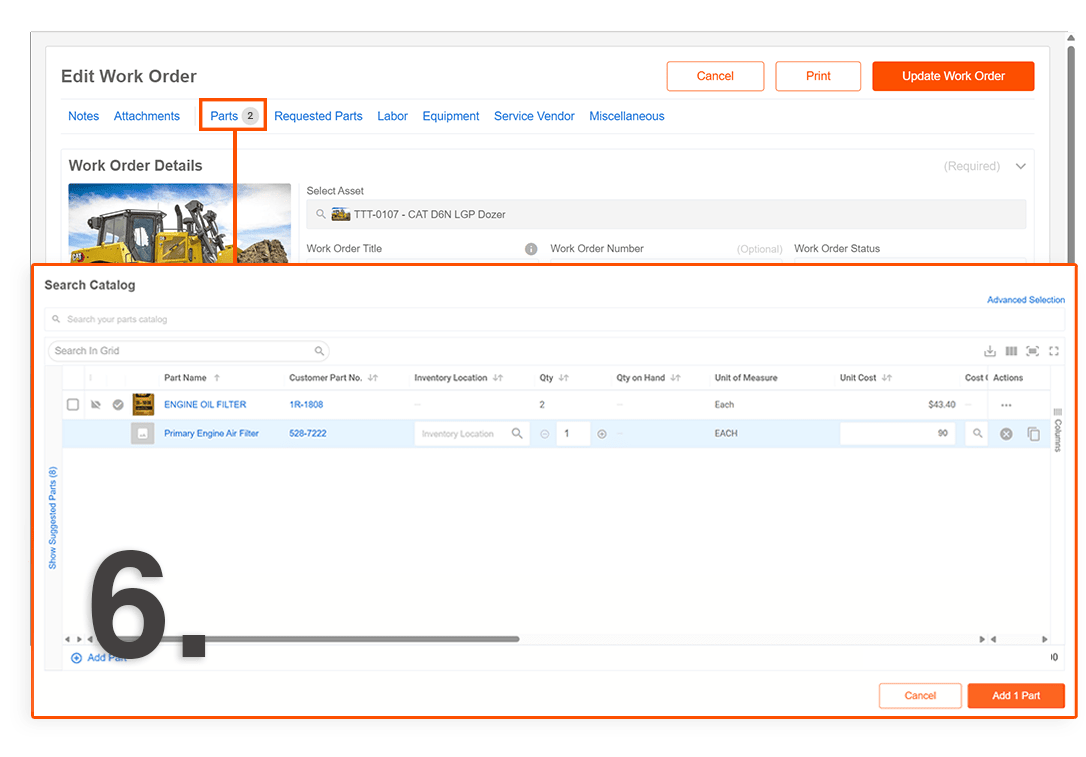

6. Seamless Work Order Integration

Connect parts to maintenance tasks or work orders. This way, when the schedule sets the service, mechanics will know what they need and what is available. Tenna integrates with Viewpoint® Vista™ ERP to accurately capture repair costs.

Ready to streamline your parts inventory process?

Tenna's Parts Inventory Overview

Frequently Asked Questions

What is construction inventory management?

Construction inventory management refers to the tracking, storing, and managing of parts, tools, and materials used in construction operations. This includes maintaining optimal inventory levels, monitoring usage, and ensuring timely availability of parts to support maintenance and project execution.

Why is inventory management important in construction?

Effective inventory management helps reduce equipment downtime, prevent overspending, eliminate redundant purchases, and improve project timelines. It ensures the right parts are available at the right time and location.

How does Tenna’s parts inventory system differ from generic inventory tools?

Tenna’s system is purpose-built for construction and integrates directly with your equipment and maintenance workflows. Unlike regular inventory tools, it provides location tracking, work order integration, and real-time visibility for construction fleets.

Can Tenna track parts across multiple locations?

Yes. Tenna allows you to manage parts inventory across shops, warehouses, and yards. You’ll know exactly what you have, where you have it, and how you use it.

Does Tenna help with maintenance scheduling?

Absolutely. Tenna combines parts inventory with equipment maintenance and work orders. This helps mechanics plan repairs with the right parts available.

Can we set alerts for low inventory?

Yes. You can set minimum quantity levels for each part. You will get alerts when stock goes below these levels. This helps prevent delays and stockouts.

Ready to See More?

Schedule a Demo