Mechanic Time Card Software for the Construction Industry

Track and Manage Mechanic Time with Accuracy and Ease

Tenna’s flexible mechanic time card is product is purpose-built to help contractors streamline how mechanic labor is recorded, tracked, approved and reported across their fleet. Construction companies rely on their shop technicians to keep equipment operational and projects on schedule — and need to know exactly how mechanic time is being spent against major cost centers.

With Tenna’s complete platform, mechanic time cards are captured digitally and directly linked to the work performed, equipment serviced, and cost codes used. Contractors gain clarity over this typical gray zone with full visibility into wrench time, labor costs, and productivity, while your mechanics get a simple, intuitive tool to log tasks on the go from the field or shop.

Benefits of Tenna’s Mechanic Time Card

Real-Time Digital Time Tracking

Technicians can log time against activities directly from their mobile devices or shop terminals. Time is captured and linked to specific equipment maintenance tasks or work orders, eliminating guesswork and late entries.

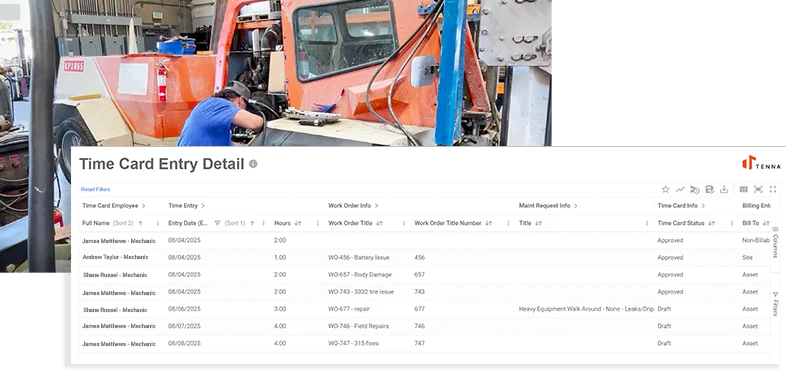

Labor Linked to Equipment and Work Orders

Every minute recorded is automatically associated with a piece of equipment, job number, or cost code. This gives you granular visibility into where mechanic time is being spent on particular machines, tasks or jobs and what it's producing.

Improved Payroll Accuracy

Mechanic hours can be reviewed, approved, and exported for payroll with confidence. No more deciphering handwriting or reconciling paper slips. Tenna streamlines mechanic labor reporting and reduces the risk of over- or underpaying.

Track Overhead vs. Time Worked on an Asset

Distinguish between working time on specific assets and jobs, overtime, lunch breaks, and other overhead hours. Use this data to optimize busy workloads, balance technician assignments, and boost efficiency in your

shop's operations.

Streamlined Maintenance and Cost Tracking

Tenna is a unified platform. This means mechanic time cards connect directly to maintenance logs, cost codes, and equipment utilization reports so labor is accurately recorded under individual costs and can be streamlined into the

payroll system.

Designed for Construction Technicians and Shop Managers

Tenna understands the realities and complexities of construction maintenance operations. Our mechanic time card solution is:

Flexible for unique mechanic labor classes and pools

Fast and easy to use in

high-paced environments

Mobile-ready for

field service techs

Customizable to your

cost centers and

maintenance workflows

Built with job costing and payroll export in mind

One Tool for Tracking Overhead vs. Productive Time

Whether your technicians are performing preventive maintenance, field repairs, inspections, or diagnostics, Tenna gives them a simple tool to log time — and gives you the powerful data behind it.

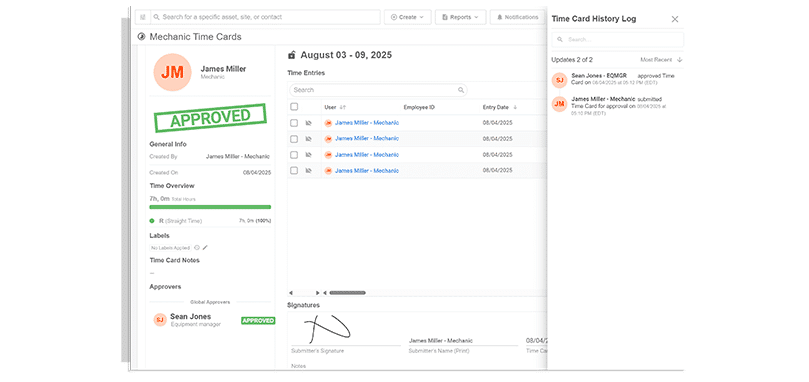

Improve Shop Visibility and Accountability

Construction companies need visibility — not just into equipment availability, but into the people keeping that equipment running. Tenna’s mechanic time card solution provides better oversight of labor productivity for frequent tasks and confidence in your maintenance reporting.

By linking all mechanical work to your equipment management platform, contractors are not just tracking time -they are also gaining valuable business insights. Users can view, filter, and customize data into reports directly from Tenna’s reporting engine.

Avoid Costly Labor Errors and Inefficiencies

Without a mechanic time tracking system, you risk inaccurate time entries, lost productivity, misapplied labor costs, disconnected reporting, and inaccurate job costing.

Tenna replaces paper slips, whiteboards, or manual spreadsheets with a reliable, integrated system that improves accuracy, compliance, and control — all while saving time for your mechanics and admins.

You can export reports and time entries from Tenna. You can also access them through an Open API connected to your ERP system. This allows for smooth data flow.

How Mechanic Time Card Works

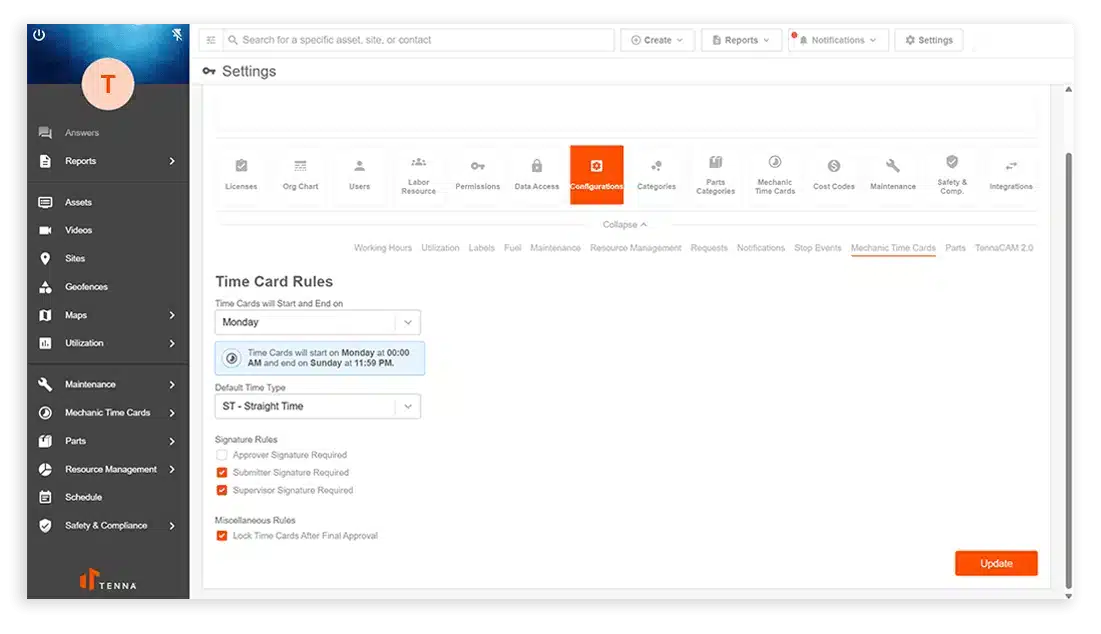

Step 1: Configure Time Cards

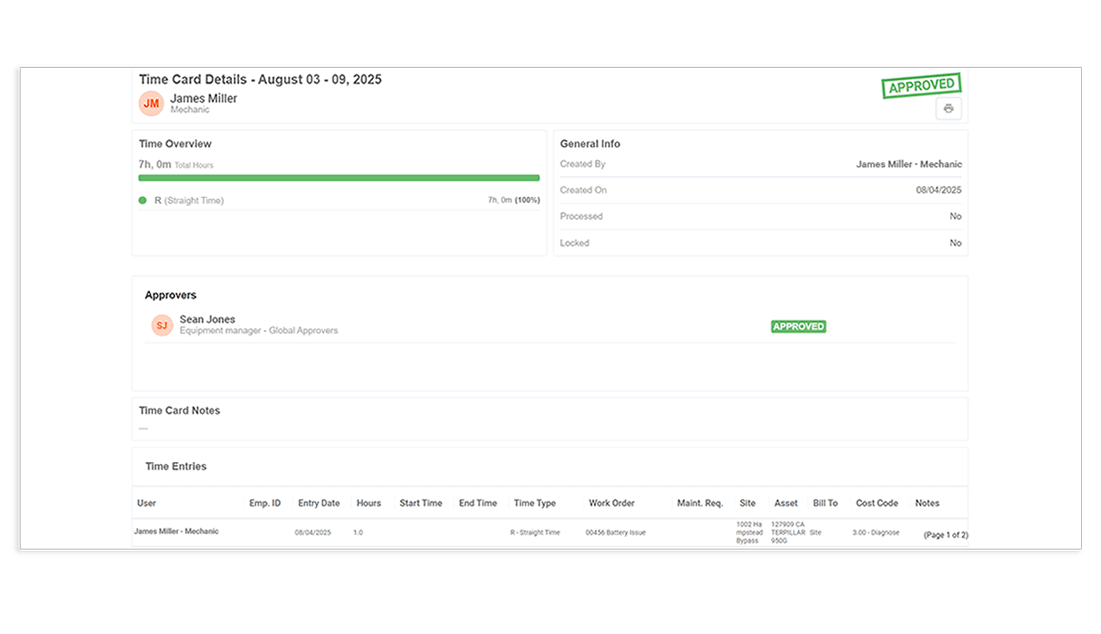

Managers can flexibly create time cards customized to their entire crew. Identify classes of work, set labor cost and billing rates for each, and define intervals and time types. Contractors can also specify and assign multiple levels of approval.

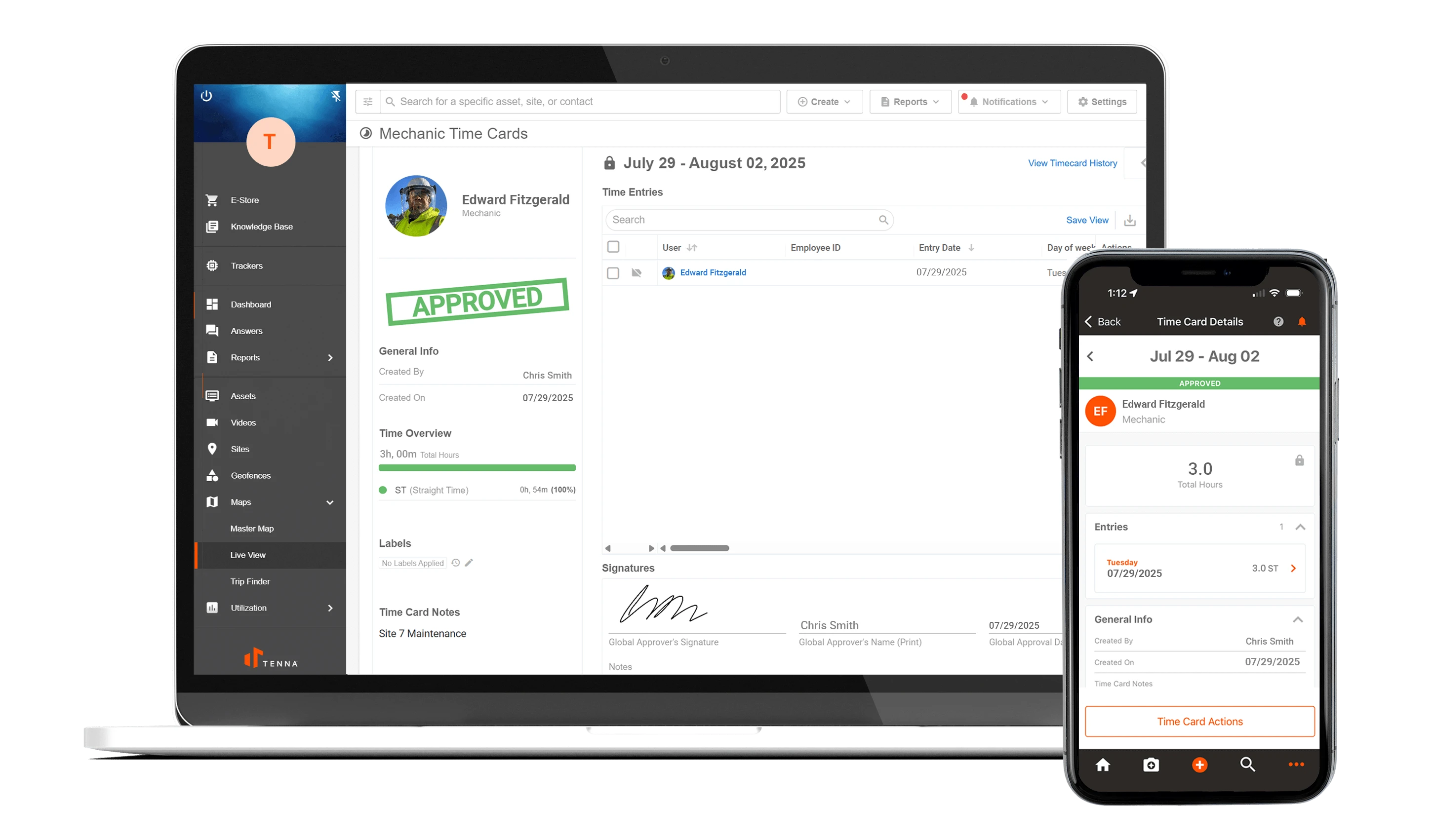

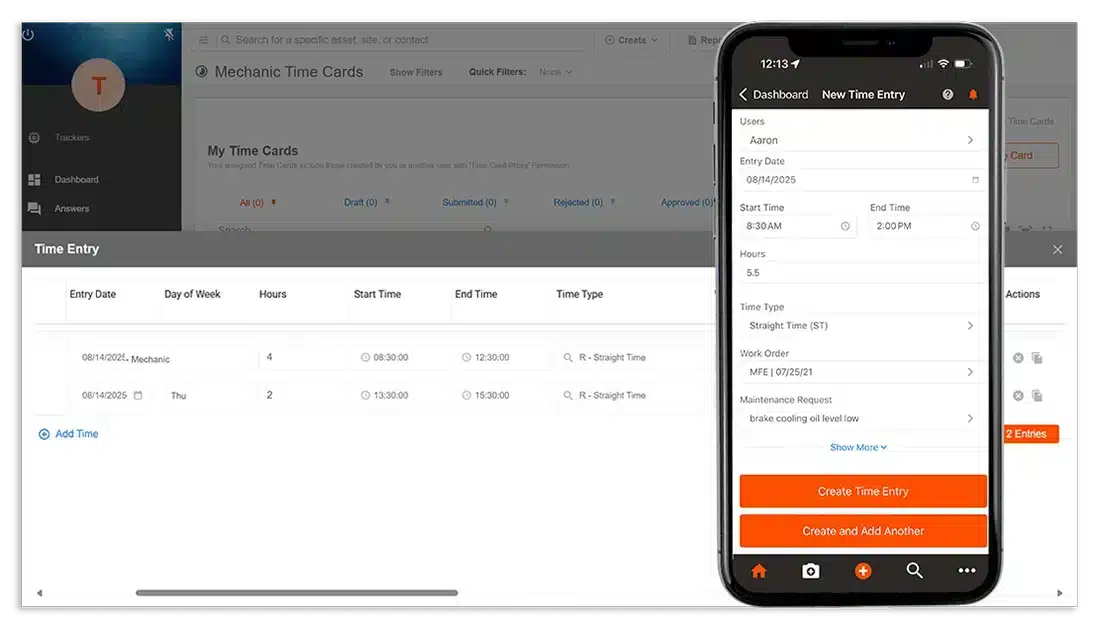

Step 2: Clock In

Mechanics start their day or task by clocking in on the Tenna app via mobile device or tablet. They select the work order or equipment they’re servicing and assign the appropriate cost code.

Step 3: Track Time by Task

As technicians complete work, time is recorded automatically in the system. They can switch tasks, pause for breaks, or add notes to provide context about repairs or delays. This makes it easy to capture and submit time on the fly and bill to appropriate cost codes.

Step 4: Review and Export

Shop managers or admins review time cards, approve hours, and export records to payroll or accounting. Time ties directly to maintenance history. This makes it easier than ever to control costs by understanding time and labor associated with tasks and truly capturing how much something costs to repair and maintain.

Want to learn more about the real cost of your equipment repairs? Hint: It goes beyond your maintenance expenses.

Get Started with Tenna’s

Mechanic Time Card Tool

Learn more about how to manage mechanic labor more efficiently with Tenna's digital time cards.

Frequently Asked Questions

What is a mechanic time card?

equipment serviced.

Why are mechanic time cards important in construction?

Mechanic time cards accurately record technician labor hours for payroll, cost tracking, and job costing. In construction, understanding how maintenance resources get used across the fleet is essential.

How do technicians use Tenna’s time card feature?

Technicians clock in and out using a mobile device or tablet. They select the work order or equipment they’re working on and log time directly to that task.

Can contractors link mechanic time to specific pieces of equipment?

Yes. With Tenna, mechanic work is linked to the specific asset being serviced. This gives detailed R&M cost and productivity insights for each machine.

Does Tenna support payroll exports?

Absolutely. You can review, approve, and export time card data in formats compatible with your payroll provider.

Can I track field mechanic time as well as shop time?

Yes. Tenna supports both in-shop and field service mechanics. Field techs can log time remotely using the mobile app.

Is mechanic time tracking integrated with cost codes?

Yes. Technicians can add cost codes to their time entries. This helps track labor costs for specific jobs, departments, or equipment.

Tell Us Your Specs!

Book a Demo