Construction Equipment Utilization Tracking

Track and Measure the True Use of Your Construction Equipment

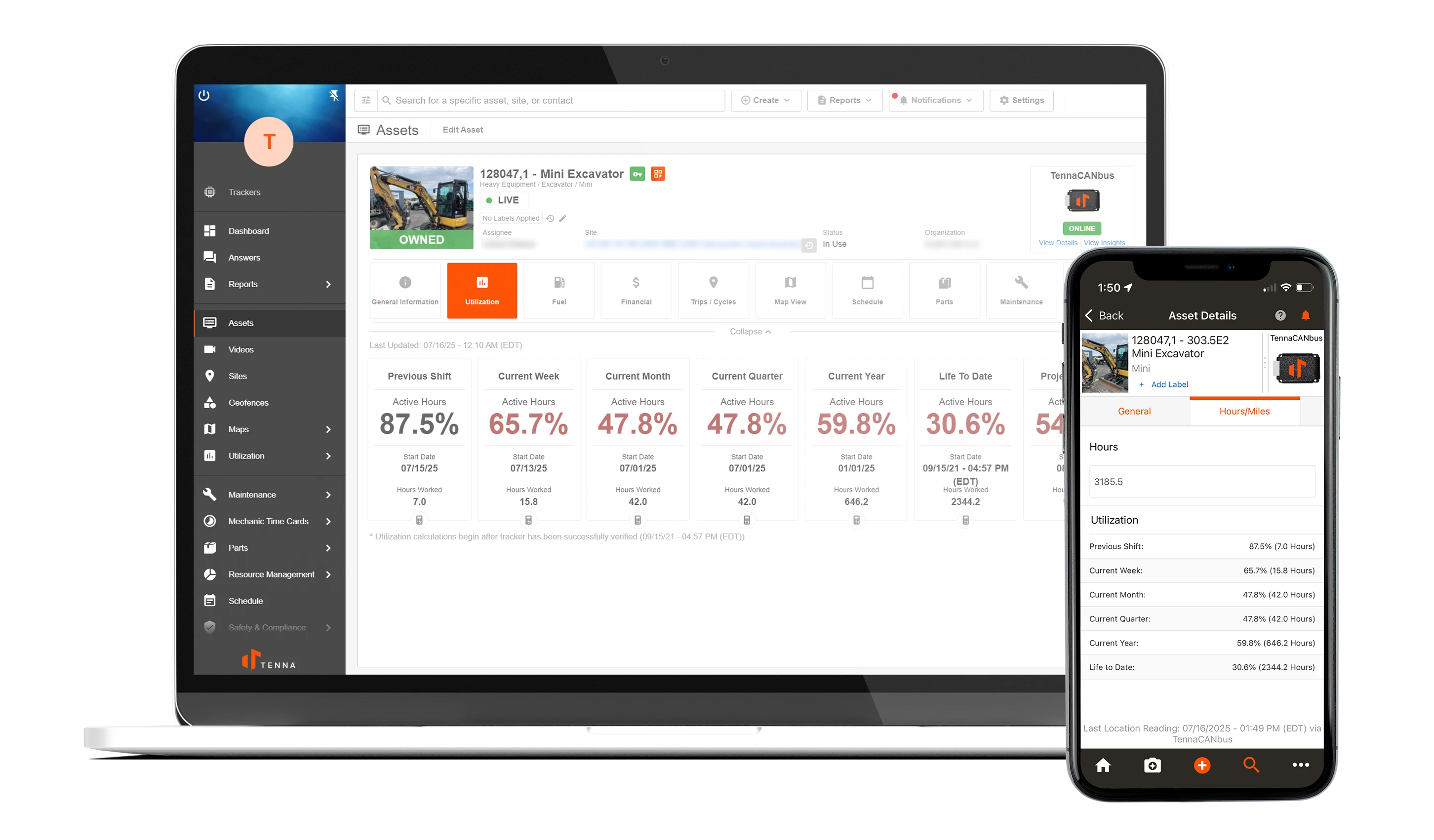

For construction companies, knowing how your machines are actually used can make or break project profitability and your overall bottom line. Tenna’s equipment utilization tracking provides a clear, real-time picture of how every asset in your fleet is performing—whether it’s running or sitting idle for days—both individually and collectively across sites. Tenna helps you cut waste, redeploy equipment where you need it most, and make better buy-move-or-rent decisions.

Tenna’s solution gathers many data points to show the complete picture of your assets’ productivity.

- Engine hours and mileage show how long and how far equipment has been working.

- Power Take-Off (PTO) engagement shows when machines are working, even if the engine is idling low.

- Idle vs. active time illustrates patterns of underuse and opportunities to rebalance your fleet.

Benefits of Tenna’s Equipment Utilization Monitoring

Maximize Equipment Utilization & Return

Get real visibility into which machines are working hard, and which are underutilized. With equipment utilization tracking, you can reassign under-used equipment, reduce idle time, and ensure every asset provides its maximum value.

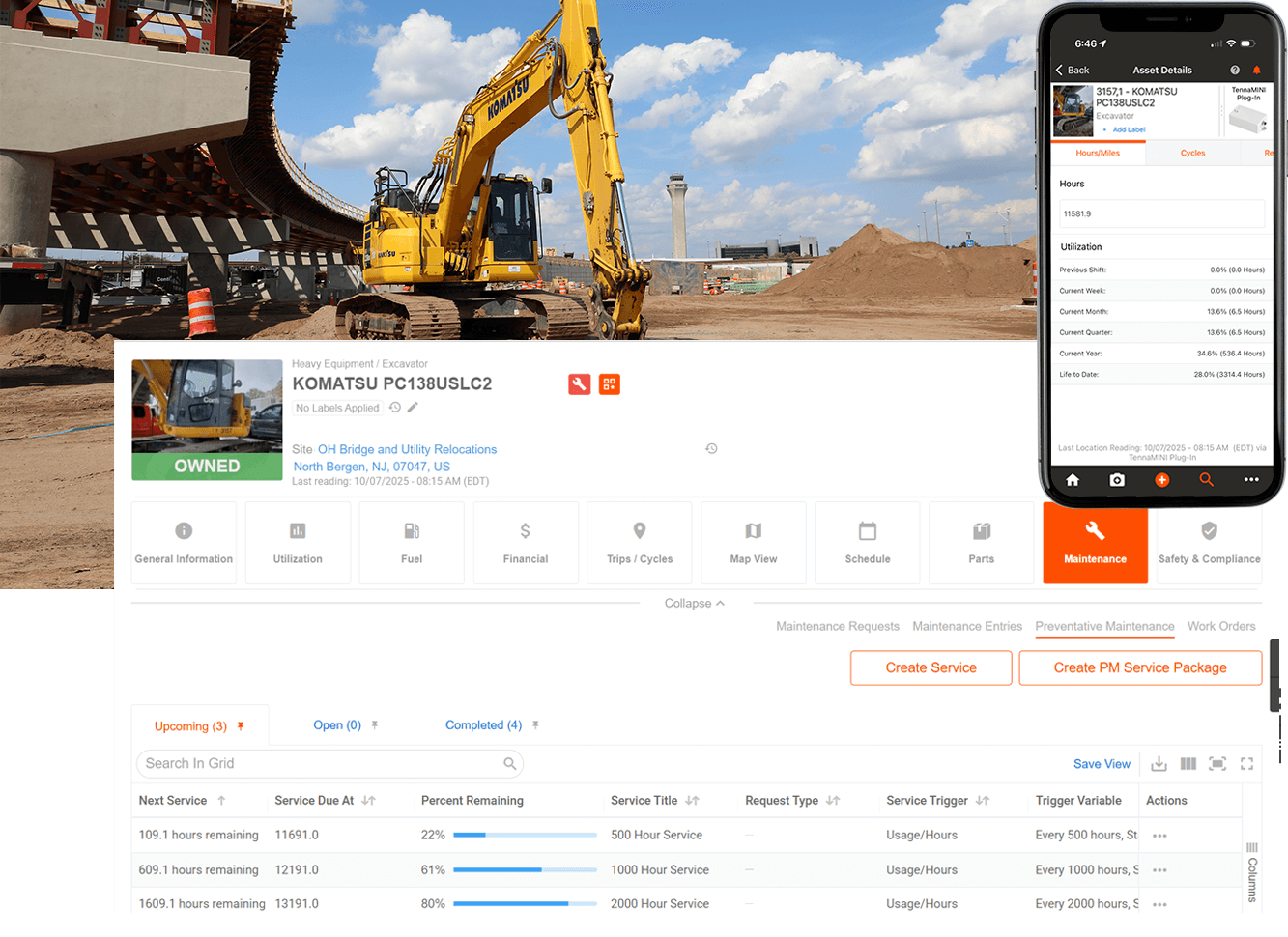

Smarter, Usage-Based Maintenance Scheduling

Move beyond calendar-based service. Trigger maintenance tasks based on actual runtime hours, PTO engagement, or other usage thresholds. Reduce breakdowns and lower total lifecycle costs.

Data-Driven Decision Making & Forecasting

Leverage historical equipment utilization trends to make more accurate purchase, rental, or retirement decisions. Predict replacement timing, avoid over-investing in slack capacity, and build accurate bid rates around real usage metrics.

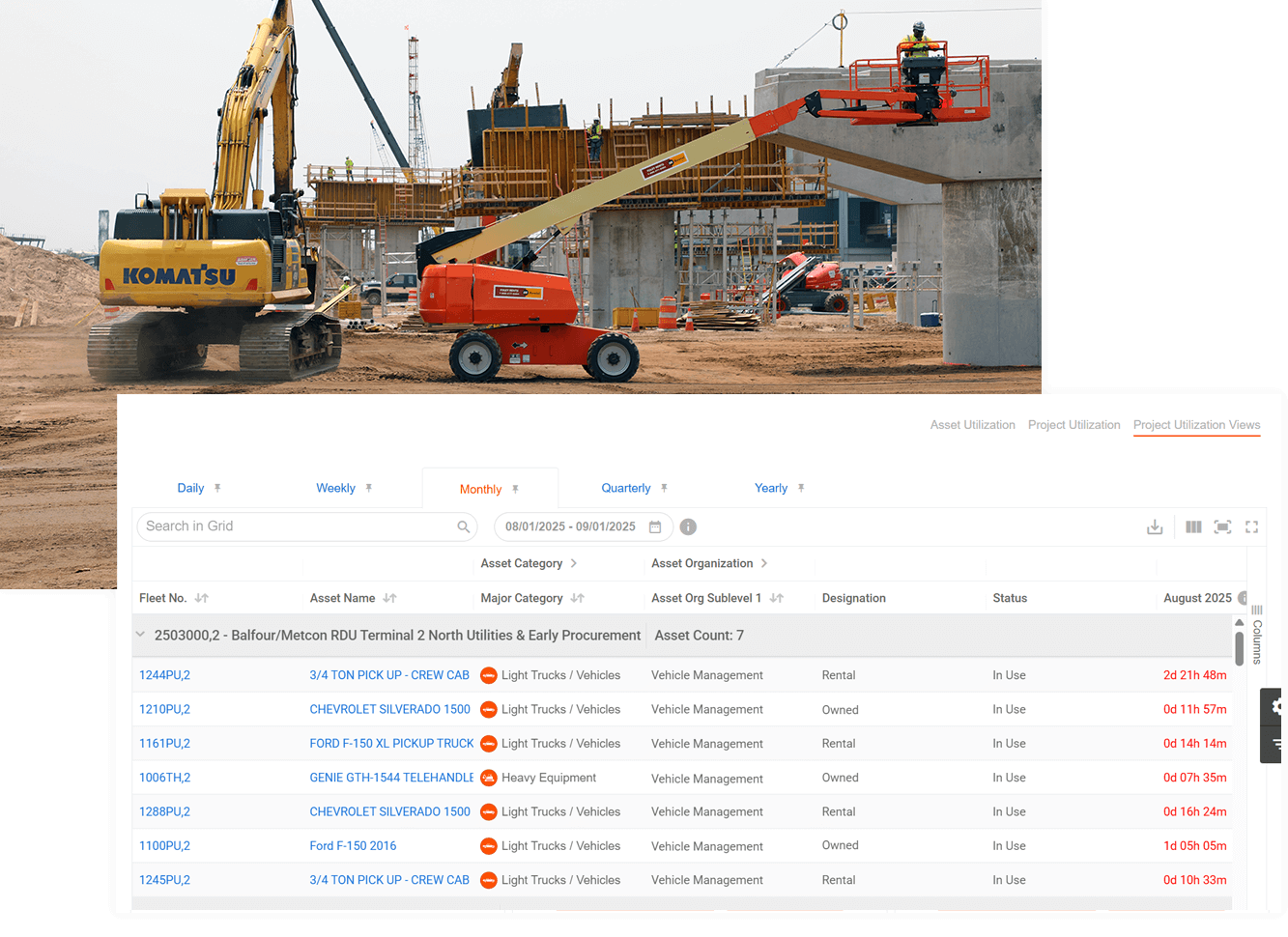

Project & Asset-Level Visibility

Filter equipment utilization by job site, or individual asset to see where inefficiencies lie. Know what machines are ready to run and which have been sitting idle to avoid inaccurate billing and crews wasting time waiting for machines to show up.

Control Costs & Optimize Fleet Size

By knowing how much equipment you really use, you can right-size your fleet and spend more wisely on rentals. This drives down fixed costs everywhere from ownership and financing to insurance and storage.

Enhanced Operational Efficiency

Cut down delays caused by misallocated equipment. Use equipment utilization data to plan deployments. Balance workloads and allocate resources. This way, each job site has exactly what it needs, when it needs it.

More Accurate Project Billing

With accurate utilization data, end-of-project billing and reconciliation is simplified.

For contractors renting out machines, this means easy gathering of utilization hours and proper billing

of clients for equipment usage.

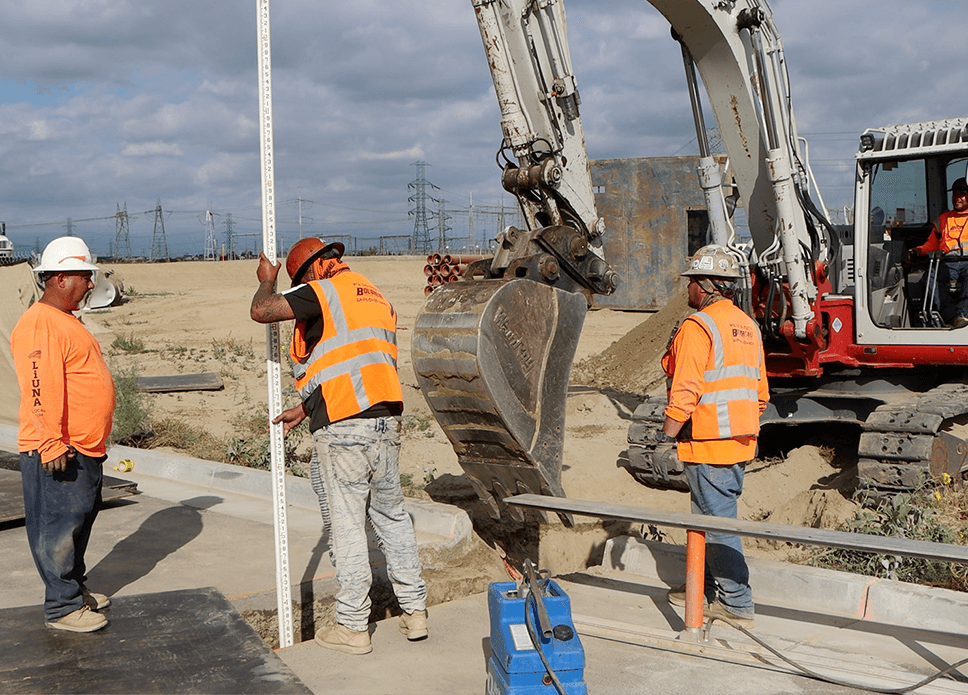

With Tenna, Boudreau Pipeline cut down 397 hours of equipment idle time in just one month. This saved an estimated $15,000 to $19,000 each month.

Why Tenna

Unlike generic GPS or telematics tools, Tenna’s equipment trackers and equipment management platform is purpose-built for the construction industry. We combine rugged tracking hardware, OEM integrations, and powerful analytics tailored to mixed fleets of heavy equipment, vehicles, and specialized machinery on the same platform as your trailers, small tool and ancillary support assets. The result is a single source of truth for fleet productivity, easily accessible from the office on the desktop or in the field on mobile.

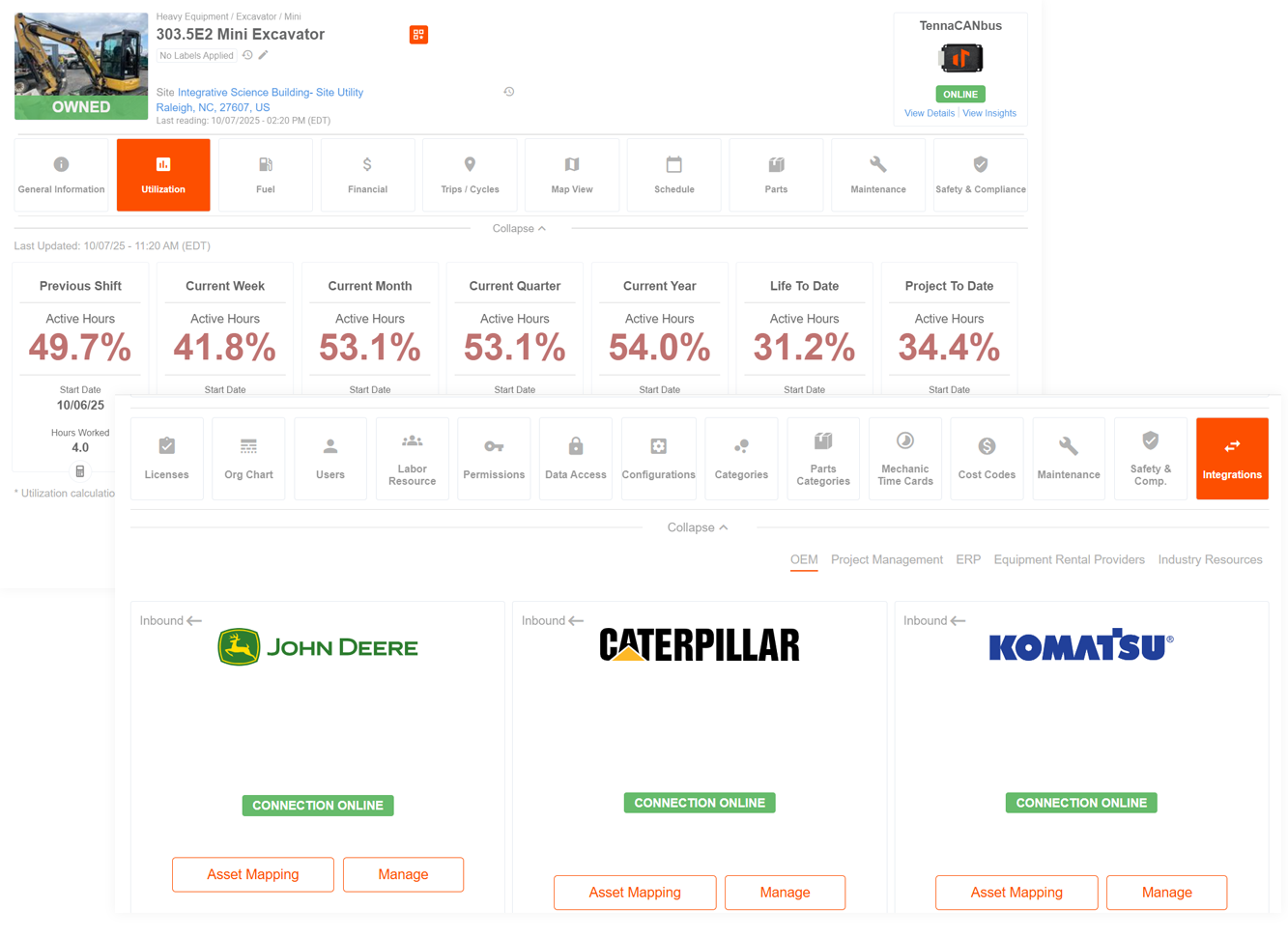

Tenna connects with OEM telematics and third-party sensors. This means all your equipment data enters one easy-to-read dashboard. Managers can track equipment usage across multiple job sites without guesswork or chasing spreadsheets and eliminate double entry.

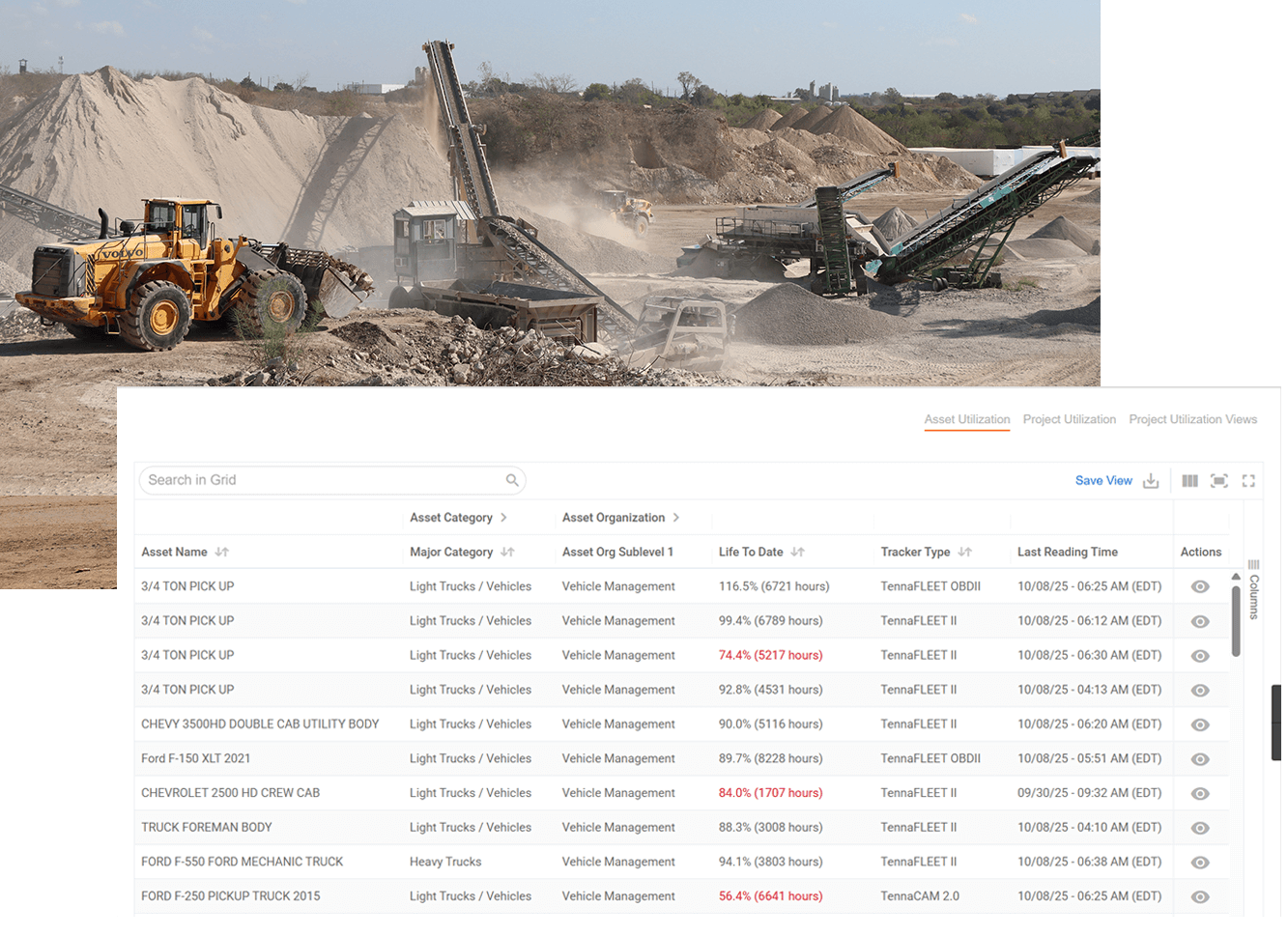

Tenna turns complex utilization data into clear, visual insights. Real-time dashboards provide a fleet-wide snapshot of which assets are busy, which are idling, and which could be moved to a different job.

Drill down into individual assets or filter by category or project to see trends and spot bottlenecks early. For deeper analyzing, build custom reports by equipment type, project, or date range.

High utilization can be a double-edged sword: it signals productivity but can also accelerate wear and tear. Tenna helps you find the right balance. It triggers preventive maintenance and routinely required inspections based on actual usage, not only time on the calendar. Tying utilization to service intervals prevents costly breakdowns in the middle of active operations causing significant schedule disruptions.

With automated alerts, your team will know when an asset hits a certain number of hours or PTO activations. This helps you schedule service at the right time, reduce downtime and extend the life of the equipment.

Estimators can bid more accurately and competitively by understanding true past usage rates. This helps them determine how long they need machines on site. This leads to stronger margins and fewer unexpected costs.

Long-term trends captured by Tenna also feed into lifecycle planning. With time, you will know when to retire, replace, or reallocate equipment. This will help you get the best return on your investments.

Want to learn more about how to measure and improve construction equipment utilization across your mixed fleet? Learn practical methods for transforming utilization data into operational improvements.

Ready to save costs with better equipment utilization tracking?

Learn more about how to track and measure equipment utilization.

Frequently Asked Questions

What is equipment utilization?

Equipment utilization is the measurement of how effectively construction equipment is used—tracking run time, idle time, and workload to show the percentage of time an asset is performing productive work.

Why is equipment utilization important?

Utilization data uncovers hidden costs. Idle or underused assets still generate depreciation, financing, and insurance expenses. Tracking utilization helps you right-size your fleet and reduce unnecessary spending.

Read more about how construction equipment data can help fuel profitability.

How do I measure utilization?

Tenna uses a mix of GPS location, engine hours, PTO activity, and telematics data. All metrics feed into dynamic dashboards and reports that reveal how, when, and where each machine works.

Learn more about Tenna’s asset tracking and management.

Can Tenna integrate with my existing systems?

Yes. Tenna works with OEM telematics, ERP systems, project management systems and other data sources. This helps you combine usage insights without entering data twice.

How does utilization tracking impact maintenance?

Maintenance schedules become usage-based rather than just date-based, preventing both premature servicing and unexpected breakdowns.

Want to See Tenna in Action?

Book a Demo