How to Master Construction Work Order Management

- Joseph Konkel

- October 2, 2025

When it comes to running construction jobs, it’s not always the big disasters that slow you down. It’s also the little things: a missing signature, a repair request that slips through the cracks, or a crew waiting around because no one told them their task changed.

At the heart of a lot of this chaos? Work orders. Or more specifically, the lack of a solid system for managing them.

If your current setup involves a mix of whiteboards, texts, spreadsheets, and crossed fingers, you’re not alone. Fortunately, the industry has greatly improved this process over recent years. These process improvements have made it easier for mechanics in the field. At the same time, they give management teams better visibility into cost tracking.

Read on to learn how to accomplish these feats.

What is a Construction Work Order?

Think of a construction work order as a play-by-play for a specific task. This tracking mechanism tells your team:

- What needs to get done

- Who is doing it

- What tools, equipment, and parts are needed

- When it should happen

- When it should be complete

- How much it is going to cost

- And any safety or compliance notes to keep in mind

It’s used for everything from managing equipment repairs to keeping up with preventive maintenance and understanding how much a contractor has invested in a piece of equipment.

No matter what the job is, a good work order system keeps everyone on the same page.

Why Poor Work Order Management is a Bigger Deal Than You Think

You have likely felt the pain: crews sitting idle, job delays, and repair requests piling up or disappearing. According to the National Utility Contractors Association and AGC, inefficient workflows and communication breakdowns are some of the biggest productivity killers in the construction industry.

FMI puts the cost of rework due to bad info and miscommunication at over $31 billion annually. So, when every contractor is attempting to reduce the cost of work, the easiest savings to achieve is simply not doing the work again.

Here’s where things usually go off the rails:

- Downtime: If a repair gets missed or a piece of equipment goes down, the ripple effect can stall a job site.

- Wasted Labor: Workers standing around or doubling up on tasks that weren’t clearly assigned.

- Cost Headaches: You can’t improve what you don’t measure, and untracked labor and parts throw your job costing way off.

- Compliance Gaps: If you’re not documenting what got fixed, when, and how, you’re asking for trouble during audits or inspections.

- Slow Cash Flow: Incomplete or missing work orders can delay billing.

The Upside of Getting It Right

When you get your construction work order system dialed in, things start tracking (pun intended):

- Everyone’s working off the same real-time info.

- Tasks and resources are matched up efficiently.

- You know exactly what each maintenance effort is costing you.

- You’re audit-ready with a digital paper trail.

Quick Breakdown: How a Construction Work Order Should Flow

Let’s walk through a typical process for contractors, which doesn’t need to be complicated.

- Request: Someone identifies a task, which could be a repair, a job assignment, or routine maintenance.

- Approval: A supervisor gives it the green light.

- Assignment: The request is matched with the right technician, equipment, and materials.

- Execution: Task gets done in the field.

- Tracking: Progress is updated and visible as work happens.

- Close Out: The work is checked and marked complete.

- Recordkeeping: All the details: costs, hours, materials are logged for reporting and billing.

Want to Get Better at This? Start With These Best Practices

Go Digital

Paper is a bottleneck. Digital work orders save time, help reduce mistakes, and make updates painless.

Use Templates

Don’t reinvent the wheel every time. Standard fields and formats keep things clean and consistent.

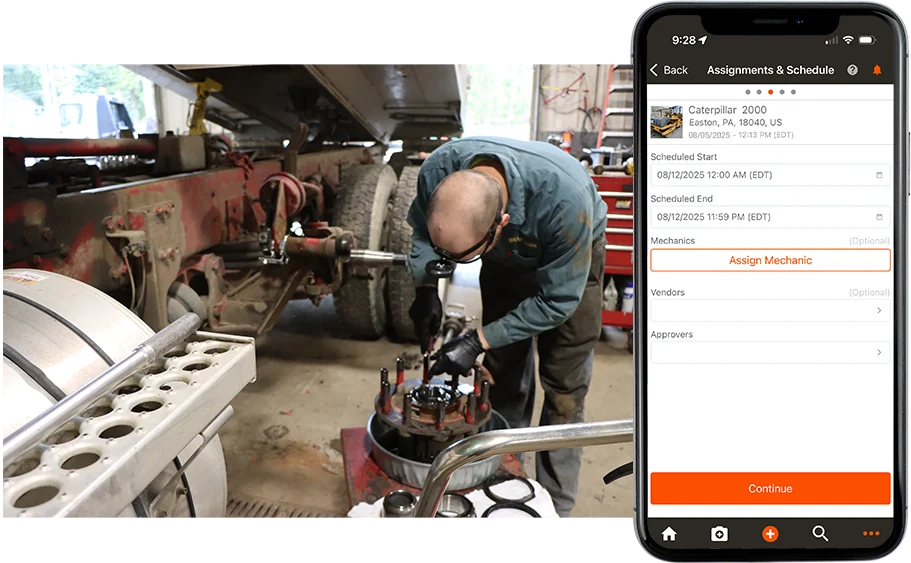

Make it Mobile

Your team is in the field: your system should be too. Real-time updates reduce phone tag and confusion.

Be Clear About Ownership

Everyone should know their role: who’s logging the work, who approves it, who closes it out.

Connect the Dots

Tie work orders to equipment logs, inventory, and service history so you get the full picture.

Track the Right Numbers

Watch metrics like average completion time, equipment downtime, and technician productivity. The data will tell you what’s working—and what’s not.

Where Tech Comes In

The best construction-specific software helps you ditch the guesswork and gives you control over the moving parts. Here’s what you can expect:

- Automation: No more manual chasing. Requests, updates, and notifications happen automatically.

- Live Views: Know where your team stands in real time.

- Inventory Sync: Parts and materials get tracked by job.

- Field-Friendly Tools: Apps your crews actually want to use.

- Smarter Planning: Use historical data to spot trends and stay proactive.

How Tenna Makes Work Orders Work for You

We built Tenna because we saw firsthand how frustrating it is to juggle equipment, crews, and schedules without the right tools. Our construction work order system plugs into your entire operation, so you’re not managing things in silos.

Here’s what that looks like in practice:

- One Platform: Work orders are tied to asset profiles, maintenance records, usage data and scheduling.

- Easy Field Access: Create and update maintenance requests and work orders straight from the job site.

- Parts & Inventory: Track what you use, what you miss, and what you need to restock.

- Mechanic Time Tracking: Keep tabs on mechanic time and directly attribute it to each work order.

- Real-Time Status: Know if something’s pending, in progress, or done. No phone calls needed.

- Actionable Insights: Get reports that actually help you make better decisions.

- ERP Integration: Connect maintenance work order records in Tenna with major ERPs to capture repair and maintenance costs.

Bottom Line: Work Orders Are the Backbone

When your work orders are dialed in, your whole operation runs smoother. Crews stay productive. Equipment uptime stays up. Costs stay accurate. And you stay in control.

If you’re ready to take the guesswork out of construction work order management, Tenna’s here to help.

Want to see it in action? Schedule a demo and we’ll show you how to make the chaos a little more manageable.

About Joseph Konkel

Joseph Konkel is a sales engineer at Tenna, where he leverages hands-on field experience and technical acumen to deliver tailored fleet management solutions that drive jobsite productivity and asset uptime. He cut his teeth in the trades as a laborer on demo and build-out projects for a general contractor in Chicago before spending six years in Health & Safety supporting ENR Top 50 firms—implementing site-safety protocols, mitigating workers’ comp costs and reducing OSHA recordables—before joining Tenna in October 2022.