2026 Guide to Fleet Maintenance Management in Construction

- Joe Messing

- July 7, 2025

Updated January 16, 2026

In the construction industry, downtime isn’t just a hassle—it’s expensive. That’s why a strategic approach to fleet maintenance management is essential for operational efficiency, safety, and profitability.

In this 2026 guide, we’ll break down what fleet maintenance management is, the unique challenges construction fleets face, and how modern tools like Tenna’s equipment maintenance software empower contractors to reduce downtime, extend asset life, and keep projects moving.

What is Fleet Maintenance Management?

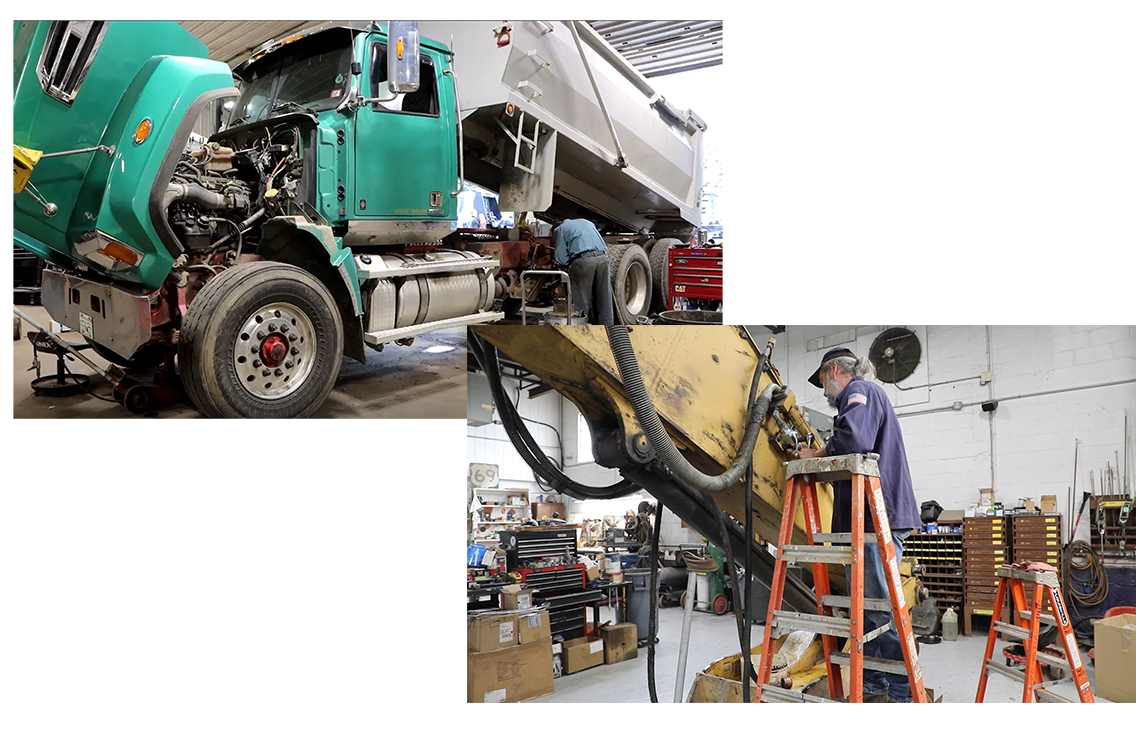

Fleet maintenance management refers to the coordinated processes, systems, and strategies used to keep a fleet of vehicles and equipment operating reliably and safely. In construction, this includes on-road trucks and vehicles, heavy trucks like articulated end dumps, yellow iron equipment like loaders, excavators, and specialized assets like rock crushers or milling machines across multiple job sites and divisions.

The primary goals include:

- Minimize Downtime: Keep equipment available when you need it.

- Extend Asset Lifespan: Reduce wear and tear through proactive care.

- Lower Operating Costs: Avoid emergency repairs and optimize fuel use.

- Enhance Safety: Prevent failures that can cause accidents.

- Ensure Regulatory Compliance: Meet inspection and reporting standards (DOT, OSHA, EPA, etc.).

Why Fleet Maintenance is Critical in Construction

Construction operations hinge on timing and equipment reliability. A single unplanned breakdown can delay crews, impact schedules, and hurt your bottom line. When you use software like Tenna, fleet maintenance becomes a data-driven process. This improves ROI and helps your valuable assets last longer.

Unlike other industries, construction fleets face:

- Continuously harsh environments (dust, mud, ice, off-road terrain)

- High-load utilization

- Variable usage across multiple job sites

- Complex regulatory requirements for both on-road and off-road assets

Common Fleet Maintenance Challenges in Construction

Even with the best intentions, maintenance can fall through the cracks. Here’s where most construction fleets struggle:

Driver/Operator Negligence or Poor Reporting

- Problem: Equipment misuse or failure to report early issues.

- Impact: Minor problems escalate to costly failures and breakdowns.

- Cause: Lack of driver/operator training or performance standards, accountability, and clear communication channels.

Unplanned Downtime

- Problem: Sudden equipment failures stop operations.

- Impact: Project delays, missed deadlines, costly emergency fixes and/or rentals.

- Cause: Inadequate preventive maintenance or aging fleets.

Inconsistent Preventive Maintenance Scheduling

- Problem: Missed service intervals or irregular inspections and lack of visibility into performance and condition.

- Impact: Reduced equipment life and increased breakdowns.

- Cause: Manual tracking or limited software automation.

Poor Maintenance Recordkeeping

- Problem: Disorganized, incomplete service and inspection histories.

- Impact: Audit risks, regulatory fines, reduced resale value and poor decision-making.

- Cause: Paper-based logs, no centralized system, human error.

Parts and Inventory Shortages

- Problem: Repairs delayed because of unavailable parts.

- Impact: Increased downtime and inflated repair costs.

- Cause: Poor inventory management, no real-time visibility, supplier delays.

|

Read more about the common challenges solved with fleet maintenance software . |

Key Components of an Effective Fleet Maintenance Program

To address these issues, a modern construction fleet maintenance program includes the following elements:

Fleet Maintenance Software

The most effective maintenance programs leverage technology, which allows contractors to do more than they ever could manually. This helps them define an effective maintenance program and track and measure success.

Tools like Tenna’s platform enable:

- Centralized service histories

- Asset-specific maintenance checklists

- Preventative maintenance scheduling and alerts (based on mileage, engine hours, or time) to avoid failures before they occur

- Ability to quickly log, track, and resolve corrective maintenance using digital work orders

- Reporting for cost analysis and forecasting

- Parts and inventory management to maintain stock levels at different locations and automate reordering and requests

- Mechanic time tracking for proper cost allocation against sites, assets, work orders and maintenance requests

Predictive Maintenance Using Telematics

Sensors and diagnostic data from Tenna’s telematics can detect:

- Engine overheating

- Battery issues

- Fluid level irregularities

- And more

This enables proactive maintenance before failure occurs.

|

Read more about what the top maintenance management systems for construction include. |

Benefits of Fleet Maintenance Management for Construction Companies

To address these issues, a modern construction fleet maintenance program includes the following elements:

Why Choose Tenna for Fleet Maintenance Management?

Tenna’s construction-specific platform is optimized for construction workflows and purpose-built for contractors with mixed fleets and in-house fleet maintenance management needs, including:

- Automated preventive maintenance scheduling

- Digital work orders and repair logs

- Integrated telematics for real-time diagnostics

- Inventory and parts tracking

- Mechanic time cards

- Integrated safety and compliance tools

- Mobile-first tools for drivers, mechanics, and fleet managers

Result: Greater visibility, lower costs, safer operations, and stronger ROI.

Fleet maintenance management isn’t just about fixing what’s broken—it’s a strategic discipline that powers construction success. With tools like Tenna, you can manage your entire maintenance ecosystem, from preventive scheduling to compliance reporting, all in one place.

|

Curious to learn more about what should be included in your fleet maintenance program? Check out Tenna’s Fleet Maintenance Checklist for both heavy equipment and on-road vehicles. Then, fill out this form for a demo, and we’ll show you how you can digitize and automate this process to keep your entire fleet running smoothly this year. |

About Joe Messing

Joe Messing is a Territory Sales Manager at Tenna, helping construction and industrial companies improve efficiency, visibility, and ROI through innovative technology solutions. With a strong background in sales, business development, and product strategy, Joe builds lasting relationships and empowers teams to succeed.