Heavy Equipment Telematics

Why Use Equipment Telematics for Construction?

Equipment, vehicles, and even attachments and tools are an expensive but necessary part of any construction business. They are also full of data that businesses can use to make better purchasing decisions, run job sites more efficiently, extend the life of expensive assets, and improve safety. Equipment telematics systems help construction companies tap into that invaluable data to grow their businesses and their bottom lines.

How Can Tenna Help Improve Your Operations with Telematics?

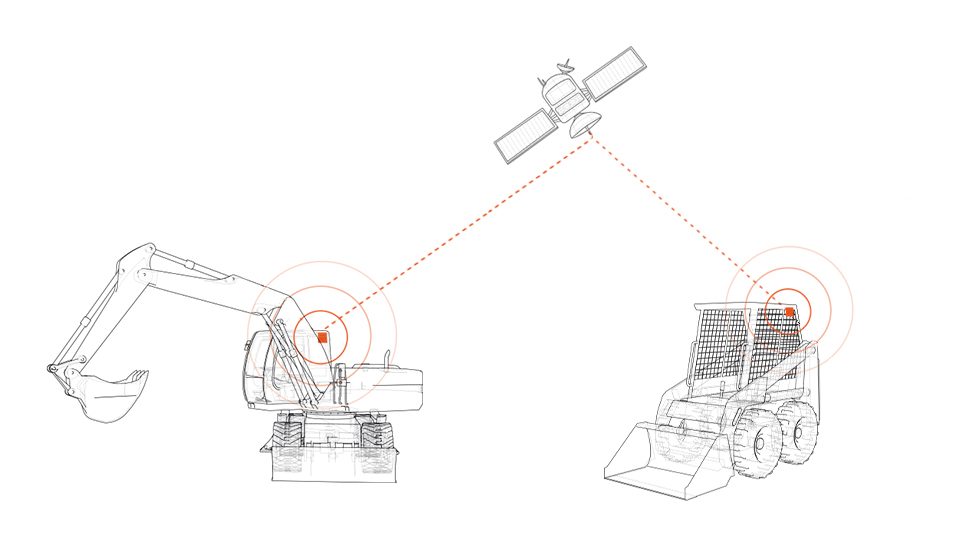

Always Know Where Your Vehicles and Equipment Are

Improving operations starts with knowing where your assets are and what they’re doing - not just when superintendents or drivers report in, but all the time. With Tenna telematics, you can remotely track and monitor your vehicles and assets 24 hours a day, seven days a week. The data gets transmitted to and securely stored in your Tenna software system, and can be used to make informed decisions about where, when and how to deploy your assets and personnel more effectively.

By knowing the exact location of every truck, vehicle, and asset in your fleet, you can streamline operations by:

- Assigning the right vehicles and equipment to the right jobsites at the right time.

- Giving customers accurate work/project completion times.

- Routing vehicles and equipment to the next job more efficiently.

To get a big-picture view of asset utilization, you can track data such as trends for trips taken, days utilized and average and peak use. You can segment the data by specific parameters, including site, location, customer and department. With this information in front of you at all times, you can make informed decisions to improve vehicle utilization and efficiency throughout your fleet.

Reduce Fuel Costs

With gas prices continuing to fluctuate - and often rise - fuel costs still represent a major operational expense for fleet businesses. With its ability to track vehicle performance in real-time, telematics helps reduce fuel costs through:

- Better routing. Telematics allows you to cut down on total miles driven by routing vehicles directly to the next destination. Driving fewer miles reduces the amount of fuel used, which automatically reduces fuel costs.

- Improved maintenance. Telematics can not only tell you when vehicles are due for maintenance, it can also identify engine problems as they occur. Keeping your vehicles in top operating condition can dramatically improve fuel efficiency and lower costs.

- Reduced speeding and idling. When drivers know their vehicles are being tracked, they tend to slow down and shut off their engines when idling isn’t necessary.

Reduced speeding also improves driver safety, and can cut down on the cost of traffic violations and expenses resulting from at-fault accidents. Many insurance companies will lower premiums when they know you use telematics to track driver performance on the road.

At the same time, tracking engine performance to manage and schedule preventative maintenance helps minimize vehicle downtime and reduce repair costs. Keeping your vehicles on the road means you can do a better job of serving customers.

Optimize Fleet and Equipment Inventory

Do you operate more assets than you need, thereby adding unnecessary operational costs? How do you know? With Tenna telematics, you can easily analyze utilization data, identify repeat maintenance issues, react to diagnostic trouble codes (DTC), compare repair costs, and accurately determine candidates for elimination, replacement, or rental.

Prevent Misuse and Theft

Knowing where your assets are and what they’re doing offers a strong deterrent to theft and unauthorized use. With telematics, you can set “geofences” that send alerts when vehicles or equipment move outside designated areas. Similarly, “odd hours” movement alerts can indicate unauthorized movement during off hours.

Fleet Management Telematics Data

Any vehicle or piece of equipment with an OBD II or SAE J1708/J1939 interface/port can get fleet management telematics data.

Engine Operated Equipment

Heavy Trucks and Service Vans

On-Road Vehicles

Benefits of Fleet Management Telematics

- Enhanced Equipment Tracking

- Increased Operational Efficiency

- Improved Maintenance Management

- Enhanced Safety

- Efficient Fuel Management

- Optimal Asset Utilization

- Improved Compliance and Documentation

- Streamlined Fleet Management

- Data-Drive Decision Making

Tenna Heavy Equipment Telematics Technology Summary

Visualize Your Fleet in Action

Schedule a Demo